ASTM A192 / ASME SA192 tubes are seamless carbon steel boiler tubes that have been developed with a high pressure that are used in boilers, superheaters and heat exchangers. SA192 tubes are also popular in power plants, refineries, fertilizer units, and thermal processing systems with high pressure requirements because of their low carbon composition, and good strength to ductility ratio.

USA Piping Solution supplies boiler tubes made according to the ASME standards, ASTM A192, with the necessary uniform quality, precision of dimensions, and long working conditions in harsh industrial conditions.

What is ASTM A192 / ASME SA192?

ASTM A192 is a material specification covering seamless carbon steel tubes intended for high-pressure boiler applications. The ASME equivalent is designated as SA192, used extensively in pressure vessel and boiler code construction.

These tubes are produced from low carbon steel (0.06–0.18%), providing excellent formability, weldability, and resistance to thermal stress. ASTM A192 tubes are commonly classified as boiler tubes rather than general-purpose heat exchanger tubes, due to their pressure-handling capability.

Looking to buy Boiler & Heat Exchanger Tubes?

Check price of ASME SA214 Boiler Tubes & SA178 Boiler Tubes

Why ASTM A192 is Preferred for High-Pressure Boilers

ASTM A192 tubes are preferred in boiler systems because they offer:

- High tensile strength suitable for elevated pressure

- Low carbon content for thermal stability

- Excellent resistance to stress cracking

- Uniform wall thickness for consistent heat transfer

- Proven performance in continuous high-temperature operation

Compared to other carbon steel tubes, A192 strikes an ideal balance between strength and ductility, making it suitable for water walls, economizers, and steam generation units.

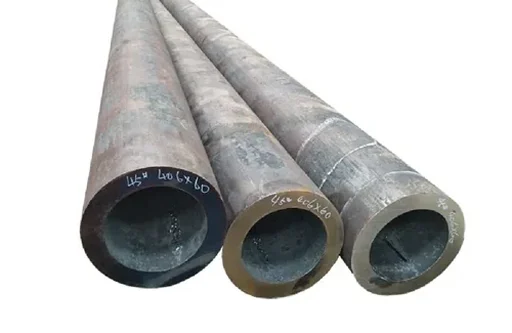

Manufacturing Process of ASTM A192 Tubes

ASTM A192 / SA192 tubes are manufactured using seamless tube production methods:

Hot Finished Seamless Tubes

- Suitable for thicker wall requirements

- Uniform grain structure

- High mechanical strength

Cold Drawn Seamless Tubes

- Tighter dimensional tolerances

- Smooth internal surface finish

- Improved heat transfer efficiency

All tubes are subjected to heat treatment as per ASTM standards to achieve the required mechanical properties.

ASME SA 192 / ASTM A192 Tube Specification

| Parameter | Specification |

|---|---|

| Standard | ASME SA 192 / ASTM A192 |

| Product Type | Carbon Steel Seamless Boiler & Heat Exchanger Tubes |

| Manufacturing Process | Hot Finished / Cold Drawn |

| Outer Diameter (O.D.) | 6.0 mm – 114.0 mm |

| Wall Thickness (W.T.) | 1.0 mm – 15.0 mm |

| Length | Up to 27,000 mm |

| Size Range | O.D.: 6.0 – 114.0 mm, W.T.: 1 – 15 mm, Length: Max 12,000 mm |

| End Finish | Plain End / Bevelled End |

| Surface Finish | Black, Pickled, Shot Blasted |

| Form | Round |

| Heat Treatment | As per ASME SA 192 |

| Testing | Hydrostatic / Eddy Current / Ultrasonic |

| Application | High-Pressure Boilers, Heat Exchangers, Steam Lines |

Chemical Composition of ASTM A192

| Element | Percentage (%) | Role in Performance |

|---|---|---|

| Carbon | 0.06 – 0.18 | Controls strength & ductility |

| Manganese | 0.27 – 0.63 | Improves toughness |

| Silicon | Max 0.25 | Enhances oxidation resistance |

| Phosphorus | Max 0.035 | Controlled to prevent brittleness |

| Sulphur | Max 0.035 | Improves machinability |

Low carbon ensures thermal stability, while controlled manganese improves pressure resistance without compromising weldability.

Mechanical Properties of ASME SA192 Tubes

| Property | Value |

|---|---|

| Tensile Strength | 325 MPa (min) |

| Yield Strength | Not specified |

| Elongation | 35% (min) |

High elongation allows the tube to absorb thermal expansion and pressure fluctuations without failure — a critical requirement in boiler operations.

Equivalent Standards & Designations of ASME SA 192

| Standard Body | Equivalent Grade |

|---|---|

| DIN (Germany) | DIN 17175 St 35.8 |

| EN (European) | EN 10216-2 P235GH |

| NFA (France) | NFA A 49-219 TU 37 F |

| UNI (Italy) | UNI C14 |

| ASTM | ASTM A192 |

| ASME | ASME SA 192 |

ASTM A192 vs A179 vs A210 Comparison

| Property | ASTM A192 | ASTM A179 | ASTM A210 |

|---|---|---|---|

| Application | High-pressure boilers | Heat exchangers | Boilers & superheaters |

| Pressure Handling | High | Low–Medium | High |

| Carbon Content | Low | Very low | Medium |

| Temperature Resistance | High | Moderate | Very High |

| Cost | Moderate | Lower | Higher |

ASTM A192 is ideal when pressure performance is required without upgrading to alloy steel

Applications of ASTM A192 / SA192 Tubes

- Power plant boilers

- Steam generation units

- Oil & gas refineries

- Fertilizer plants

- Heat recovery systems

- Industrial heat exchangers

ASTM A192 tubes undergo strict quality checks to ensure reliable performance in high-pressure boiler applications, including hydrostatic or non-destructive testing, flattening and flaring tests, detailed chemical analysis, mechanical property verification, and precise dimensional inspection; all supplied tubes fully comply with applicable ASTM and ASME code requirements.

Looking to buy Boiler & Heat Exchanger Tubes?

Check price of SA192 Boiler Tubes & SA178 Boiler Tubes

Explore our full range of carbon steel boiler and heat exchanger tubes engineered for high-performance industrial applications.

Request Your A192 Tubes / SA192 Tubes Tubing Quote Today!Related Products

Frequently Asked Questions About SA192 Tubes

What pressure can ASTM A192 tubes handle?

ASTM A192 tubes are designed for high-pressure boiler service and are commonly used in steam and water circulation systems.

What is the maximum temperature for SA192 tubes?

SA192 tubes perform reliably in elevated-temperature boiler environments, typically up to approximately 540°C, depending on system design and operating conditions.

Can ASTM A192 be replaced with A179?

ASTM A179 is primarily used for heat exchangers and is not recommended for high-pressure boiler applications where ASTM A192 is required.

Is SA192 suitable for welding?

Yes, due to its low carbon content, SA192 offers excellent weldability and is well-suited for boiler fabrication.

.webp)