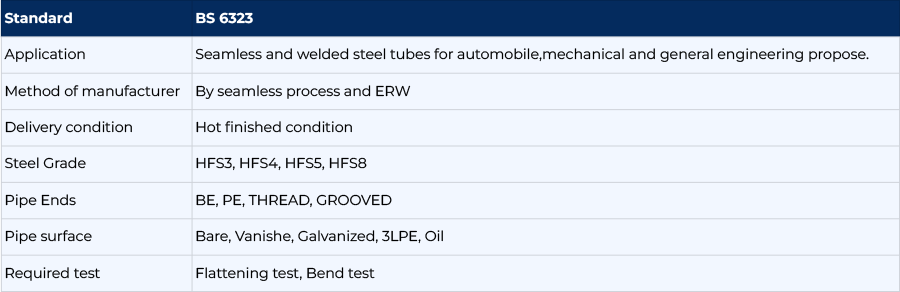

The BS 6323 is a British Standard created by the British Standards Institution (BSI) which provides guidelines and specifications of seamless and welded steel tubes to be used in the mechanical, structural and the general engineering applications. This standard covers various tube types, with a specific emphasis on cold-worked seamless steel tubes, alongside cold drawn and standard welded tubes.

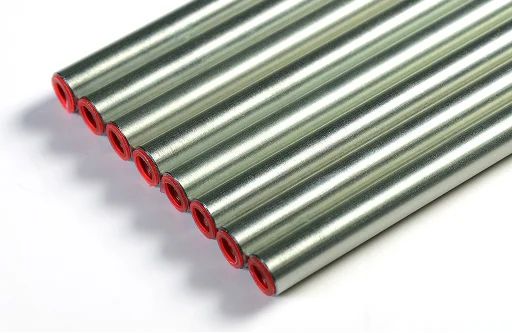

Our BS 6323 Carbon Steel tubes are manufactured in strict adherence to this standard, guaranteeing high-quality, cold-finished seamless tubes suitable for the automobile, mechanical, and general engineering sectors. By strictly following the stringent BS 6323 guidelines in our manufacturing process, we ensure the precision, robustness, and reliability of our products, which possess excellent properties that make them an ideal bs 6323 equivalent for certain international standards.

Table of Contents

BS 6323 Steel Grades

We offer BS 6323 steel tubes in a wide variety of grades, including: 3, 3A, 4, 5, 6, 7, 8, 9, 10, and 11.

Each of these grades is tailored to specific applications to ensure optimal performance. For instance, common grades often associated with different manufacturing routes include:

HFS3 (Hot-Finished Seamless Grade 3)

HFS4 (Hot-Finished Seamless Grade 4)

HFS5 (Hot-Finished Seamless Grade 5)

HFS8 (Hot-Finished Seamless Grade 8)

By specifying your desired grade during the enquiry, you can be assured of a product that aligns perfectly with your project’s requirements.

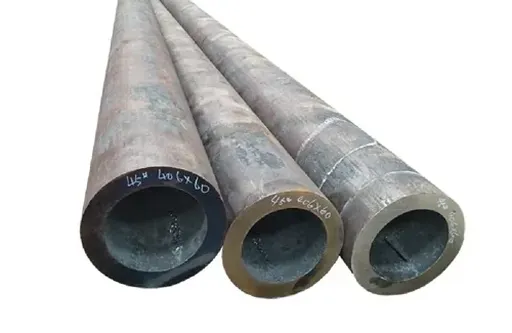

BS 6323 Specifications

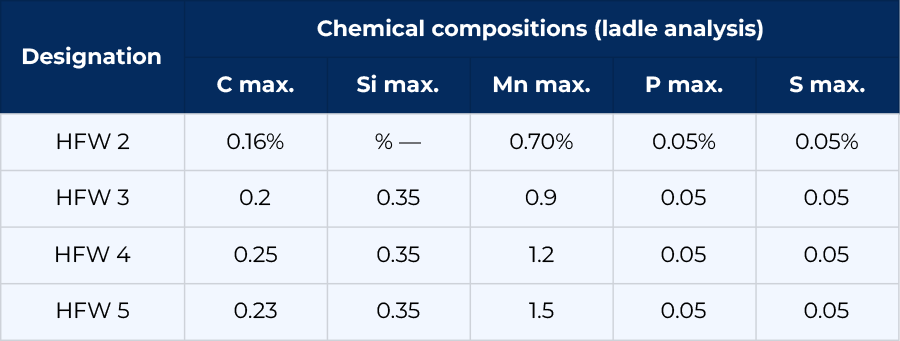

Chemical Composition of BS 6323 Carbon Steel Tubes

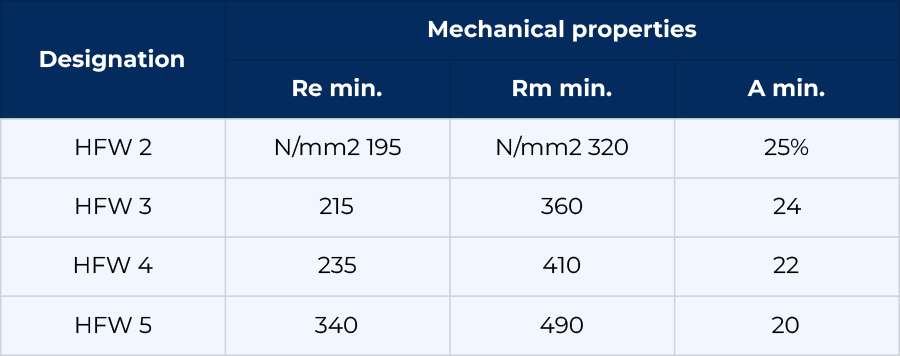

BS 6323 Seamless Tubes Mechanical Properties

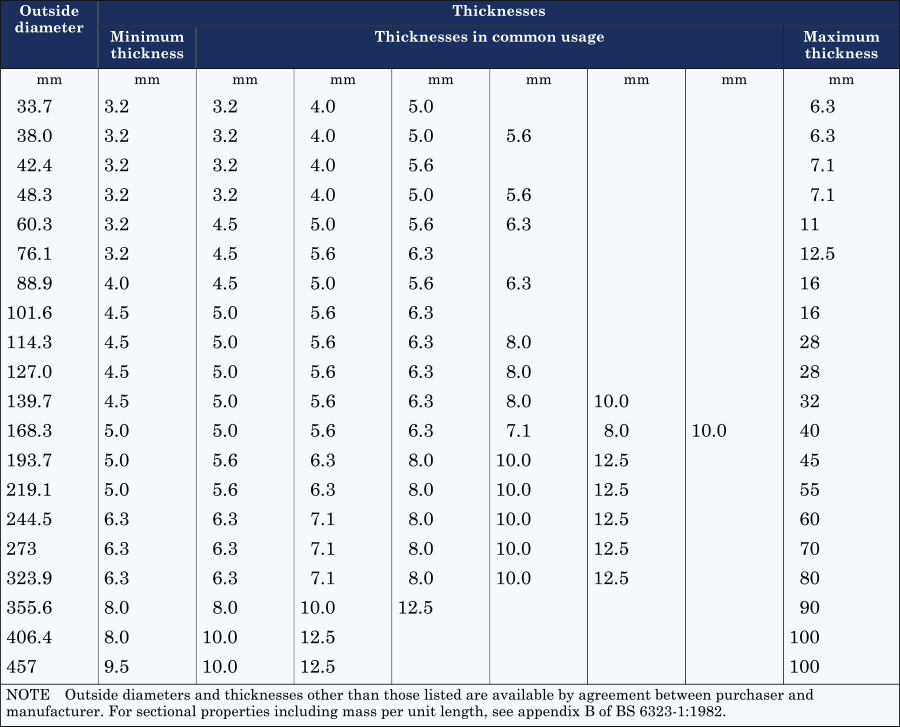

Dimensions of BS 6323 Hot Finished Seamless Tubes

Applications of BS 6323 Carbon Steel Seamless Tubes

Our BS 6323 Seamless Tubes are engineered for highly demanding applications, particularly in the petrochemical industry. These tubes are built to withstand severe operating conditions, including high temperatures, corrosive environments, and varying pressures, ensuring maximum reliability and safety in complex petrochemical processes.

Whether the task involves transferring crude oil, natural gas, or chemical intermediates, the exceptional robustness and versatility of these BS 6323 Carbon Steel tubes make them indispensable components of plant infrastructure. Their use contributes significantly to efficient production and helps maintain the stringent safety standards required across the entire petrochemical sector.

.webp)

Related Products

Are you looking for high-quality Carbon Steel Pipes & Tubes that meet the stringent BS 6323 specification? For competitive pricing and to discuss your exact project requirements, Contact us today.

Request Your BS 6323 CFS 3 Tubing Quote Now!