Effective thermal management is fundamental in industry, often relying on crucial components like Heat Exchanger Tubes & Pipes. These aren't just conduits; they dictate system efficiency and lifespan. At USA Piping Solution, we specialize in these vital parts. We know quality tubing underpins reliable operations. This drives our commitment: extensive inventory, precision manufacturing, and diverse configurations. For HVAC, power, chemical, or oil & gas needs, USA Piping Solution is your knowledgeable partner for Heat Exchanger Tubes & Pipes.

What are Heat Exchanger Tubes & Pipes?

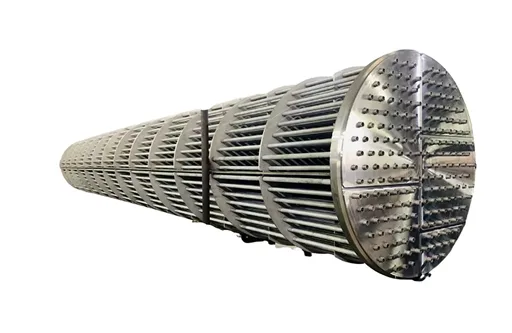

Their core job? Heat Exchanger Tubes & Pipes create pathways for heat transfer between different fluids within an exchanger, acting as a solid barrier. This separation allows heat conduction through the tube wall without fluids mixing. Good design maximizes surface area while ensuring the tubes withstand pressure, temperature, and corrosion. Whether bundled in shells or meeting airflow, from basic Heat Exchanger Boiler Pipes to complex U Tube Heat Exchangers, tube quality dictates system success.

Heat Exchanger Tubes & Pipes Specifications

Choosing the right specifications for Heat Exchanger Tubes & Pipes impacts performance, safety, and cost. The optimal choice depends on the application: fluids, temperatures, pressures, flow rates, and exchanger design. USA Piping Solution offers the necessary range to meet these technical needs.

Materials (SS 304/316, Alloy Steel, Copper, Titanium)

Material selection governs heat transfer, corrosion resistance, strength (especially when hot), and budget. We supply key industry materials:

- Stainless Steels (SS): Balance corrosion defense, strength, and value.

- SS 304/304L: Versatile standard for general use; 'L' grade aids welding.

- SS 316/316L: Molybdenum boosts resistance to chlorides/acids. Stainless Steel Heat Exchanger Pipes in 316L handle tougher jobs (marine, chemical).

- Duplex SS: Higher strength and specific corrosion resistance for demanding oil & gas or chemical applications.

- Carbon Steel: Economical for non-corrosive fluids at moderate temps (e.g., Seamless Heat Exchanger Tubes per ASTM A179).

- Alloy Steel: Enhanced with Cr/Mo for high-temp strength and creep resistance. Vital for power plants (Heat Exchanger Boiler Pipes) and refineries (often ASTM A213 Tubes).

- Copper & Alloys: Excellent heat conductors, resist biofouling. Ideal for seawater cooling (ASTM B111).

- Titanium: High strength-to-weight, exceptional corrosion resistance. Top performance where cost is justified.

- Nickel Alloys: Peak performance for extreme heat/corrosion where other metals fail.

Forms (Seamless, Welded, U-Bend, Fin Tubes)

How the tube is made affects its properties

- Seamless Heat Exchanger Tubes: No weld seam, uniform strength. Best for high pressure/temperature or critical integrity needs.

- Welded Tubes (ERW/TIG): Reliable, often tighter tolerances, cost-effective for many moderate applications.

- U-Bend Tubes (for U Tube Heat Exchangers): Accommodate thermal expansion, can simplify design, often ease maintenance.

- Fin Tubes: Increased surface area (external/internal fins) boosts heat transfer, especially between liquids and gases.

Chemical Composition and Mechanical Properties

Accurate chemical and mechanical data is crucial for design and safety. USA Piping Solution provides full traceability via certified Mill Test Reports (MTRs).

(Note: Values are typical; refer to specific standards and MTRs.)

Chemical Makeup (Typical %)

| Material Identifier | C (max) | Mn (max) | Si (max) | Cr Range | Ni Range | Mo Range |

|---|---|---|---|---|---|---|

| Base Carbon (A179) | 0.18 | 0.63 | - | - | - | - |

| Standard SS (304) | 0.08 | 2.00 | 0.75 | 18.0-20.0 | 8.0-10.5 | - |

| Moly SS (316) | 0.08 | 2.00 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Cr-Mo Alloy (T11) | 0.15 | 0.60 | 1.00 | 1.0-1.5 | - | 0.44-0.65 |

| Copper-Nickel (90/10) | - | 1.0 | - | - | 9.0-11.0 | - |

Mechanical Strength (Typical Minimums)

| Material Identifier | Tensile (ksi/MPa) | Yield (ksi/MPa) | Elong. (%) | Hardness (max) |

|---|---|---|---|---|

| Base Carbon (A179) | 47 / 325 | 26 / 180 | 35 | 72 HRB |

| Standard SS (304) | 75 / 515 | 30 / 205 | 40 | 92 HRB |

| Moly SS (316) | 75 / 515 | 30 / 205 | 40 | 95 HRB |

| Cr-Mo Alloy (T11) | 60 / 415 | 30 / 205 | 30 | 85 HRB |

| Copper-Nickel (Ann.) | 40 / 276 | 15 / 103 | 35 | Varies |

Applications and Industries Served

Quality Heat Exchanger Tubes & Pipes are vital across diverse sectors:

- Power Generation: Condensers, feedwater heaters, boilers.

- Chemical Processing: Reactors, coolers, heaters handling various chemicals.

- Oil & Gas: Upstream, midstream, and downstream thermal management.

- HVAC & Refrigeration: Chillers, air conditioning, industrial cooling.

- Food & Beverage: Hygienic heating/cooling (Stainless Steel Heat Exchanger Pipes common).

- Petrochemicals: Supporting production of plastics, fertilizers, etc.

- Pharmaceuticals: High-purity temperature control.

- Marine & Desalination: Seawater cooling, freshwater production.

- Pulp & Paper: Handling demanding process conditions

Heat Exchanger Tubes & Pipes Size Chart

We stock common sizes and assist with sourcing custom dimensions.

(Note: Availability varies by material/form. Please inquire.)

| Parameter | Common Imperial Specs | Common Metric Specs | Notes |

|---|---|---|---|

| Outer Diameter | 0.250" thru 4.000"+ | 6.35 mm thru 101.6 mm+ | Wide range covered. |

| Wall Thickness | BWG 22 up to 7 (~.5") | 0.71 mm up to 12.7 mm | Light to heavy wall avail. |

| Length | Standard up to 60 ft+ | Standard up to 18 m+ | Custom cuts standard. |

| U-Bend Radius | Per Design/Standard | Per Design/Standard | Dictated by project needs. |

Manufacturing Standards & Certifications

Adherence to international standards (ASTM, ASME, EN/DIN) is fundamental for quality and safety.

We supply tubes manufactured and tested accordingly, covering key specs like:

- ASTM A179 / ASME SA179 (Seamless Carbon)

- ASTM A213 / ASME SA213 (Seamless Alloy/Stainless, includes ASTM A213 Tubes)

- ASTM A249 / ASME SA249 (Welded Austenitic)

- ASTM B111 / ASME SB111 (Seamless Copper Alloy)

Our quality systems ensure compliance. Full documentation, including Mill Test Reports (MTRs) verifying chemical/mechanical properties and testing, is provided.

Why Choose USA Piping Solution for Heat Exchanger Tubes & Pipes?

Partnering with us offers clear advantages:

- Responsive Inventory: Faster access to diverse materials (Seamless Heat Exchanger Tubes, Welded, U Tube Heat Exchangers) and sizes.

- Verified Quality: Strict adherence to standards and rigorous testing mean reliable performance.

- Informed Guidance: Technical expertise to help you select the optimal tubing solution.

- Tailored Capabilities: Custom cutting, U-bending, and end preps to meet exact design needs.

- Reliable Logistics: Focused on accurate, on-time delivery to keep projects moving.

- Partnership Approach: Responsive communication and commitment to finding effective solutions.

Related Products

Explore our wider range of piping essentials:

Final Call to Action

For dependable, high-quality Heat Exchanger Tubes & Pipes designed for demanding industrial service, trust USA Piping Solution. Leverage our inventory, quality commitment, and expertise for efficient, long-lasting thermal systems.

Contact USA Piping Solution today to discuss your requirements, request a competitive quote, and secure the optimal Heat Exchanger Tubes & Pipes for your application's success.

Request Your Heat Exchanger Tubes & Pipes Quote Today!