ASTM A335 P11 High Pressure Steel Pipes Manufacturer and Supplier

The USA Piping Solution is a large manufacturer and dealer in India of the ASME SA335 Grade P11 High-Pressure Steel Pipes. We are able to offer the ASTM A335 P11 seamless and ASTM A335 P11 ERW Pipe based on the requirements of various projects. The ASTM A335 P11 Pipe is constructed using high quality alloy steel and the mechanical property is of good quality as the tensile strength is minimum of 415 Mpa and the yield strength is 205 Mpa. It contains excellent toughness, wear resistance, heat strength, and corrosion resistance as it contains carbon, manganese, silicon, chromium, and molybdenum.

Its high chromium content also contributes greatly to resistance against oxidation which makes the ASME SA335 Grade P11 Chrome Pipe to be used under extreme oxidizing and high-temperature conditions. Molybdenum also increases wear resistance, elasticity and strength. The resultant ASM SA335 Grade P11 Pipe is used in high-pressure types of utilization like spacecraft, jet engine turbine blades, and nuclear reactors. Also, the material can be utilized in electric motors and transformers because of the magnetic qualities inherent in the material.

We sell the full line of products, such as Alloy Steel Seamless Pipes & Tubes. This consists of all dimensions and types, including P11 Alloy Steel Welded Pipe. We also supply any size and quantity of ASME SA335 Grade P11 Chrome Pipe. Call us with any questions about the products, and our price catalog.

Table of Contents

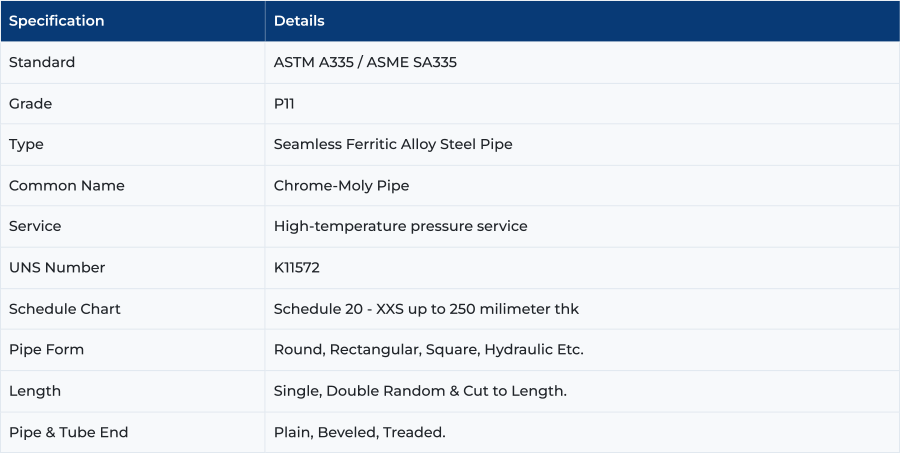

- ASTM A335 P11 Seamless Pipe Specifications

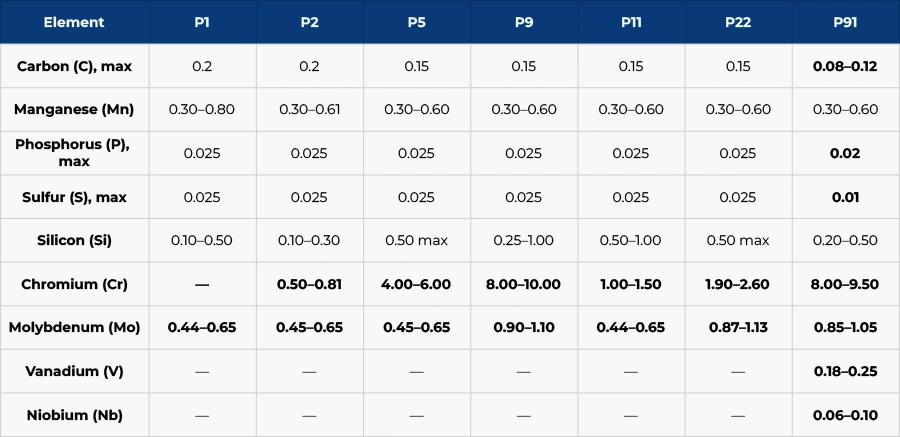

- Chemical Composition of ASTM A335 P11 Pipes

- Mechanical Properties of ASME SA335 Grade P11 High Pressure Steel Pipe

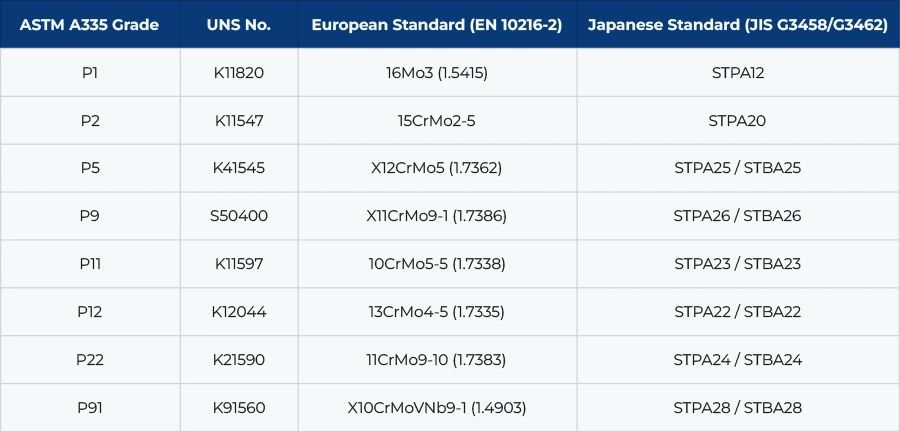

- Equivalent Grades of ASME SA335 Grade P11 Chrome Pipe

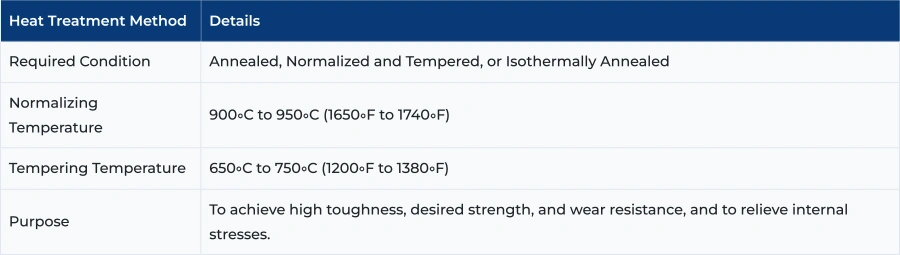

- Heat Treatment of ASTM A335 P11 Alloy Steel Pipe

- Dimensions of ASTM A335 P11 Alloy Steel Seamless Pipes

- Applications of ASTM A335 P11 Seamless Pipes

ASTM A335 P11 Seamless Pipe Specifications

This table outlines the primary standards and characteristics of the Grade P11 pipe.

Chemical Composition of ASTM A335 P11 Pipes

Mechanical Properties of ASME SA335 Grade P11 High Pressure Steel Pipe

Equivalent Grades of ASME SA335 Grade P11 Chrome Pipe

Heat Treatment of ASTM A335 P11 Alloy Steel Pipe

Proper heat treatment is applied to the A335 P11 Alloy Steel Pipe to achieve the specified mechanical properties and enhance the overall structure.

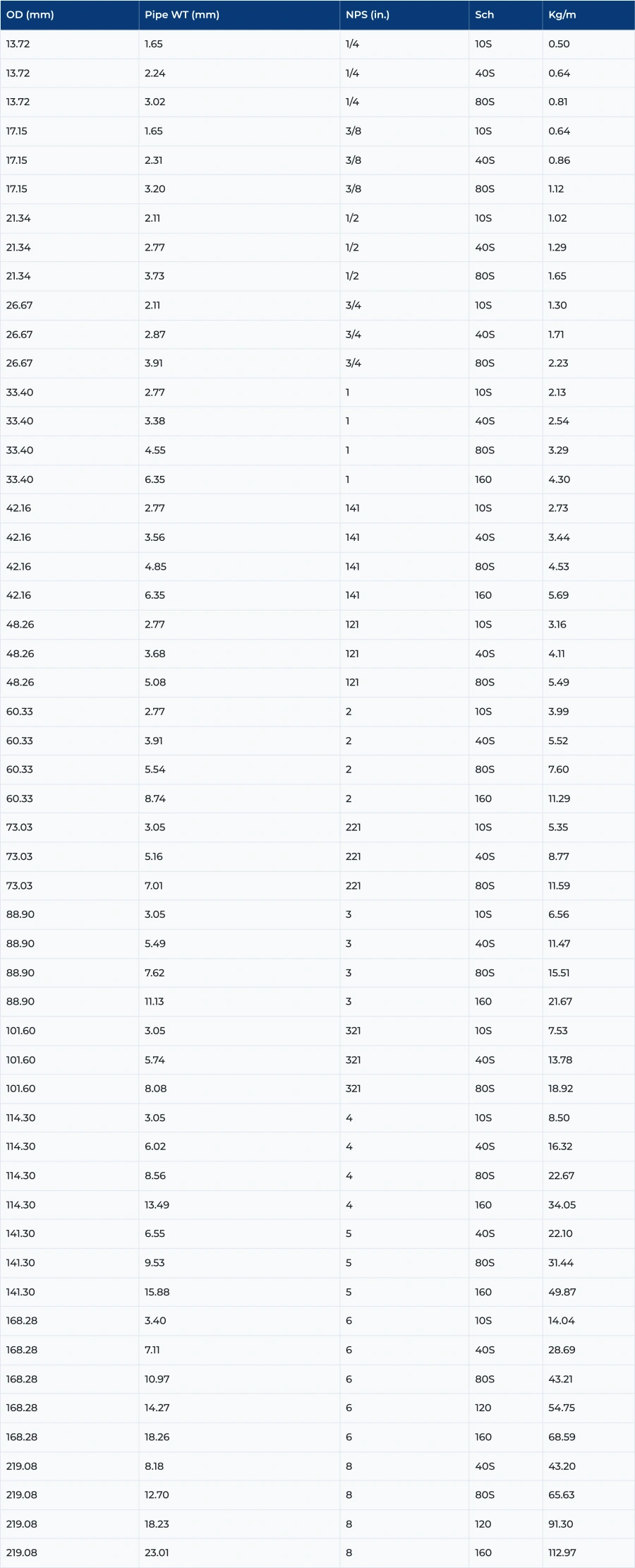

ASTM A335 P11 Alloy Steel Seamless Pipes Dimensions

The dimensional standards of the ASTM A335 Grade P11 Seamless Pipes (AS P11 Grade Material) are mainly determined by the Nominal Pipe Size (NPS) and Schedule (Sch) types. The table below will give the Outer Diameter (OD) and Wall Thickness (WT) in millimeters, and the weight per meter (Kg/m) which is approximately.

Applications of ASTM A335 P11 Seamless Pipes

- Medium-pressure boiler systems: Including steam lines and headers operating at up to 540°C.

- Petrochemical facilities: For process piping carrying steam, oil, and corrosive media.

- Fossil fuel and thermal power plants: Used in reheater tubes and economizers.

- Refinery process piping: In systems requiring moderate heat resistance and dimensional stability.

- Heat exchangers and pre-heaters: Where resistance to thermal stress is crucial.

Explore our full catalog of Alloy Steel Pipes & Tubes to uncover their wide range of applications and detailed specifications.

Get a Quote for ASTM A335 P11 Chrome Moly Pipes Today

Require a source of ASTM A335 P11 pipes that are fabricated to be used in a moderate to a high-temperature setting? The P11 seamless pipes provided by USA Piping Solution are highly professional manufactured and can be custom-made according to length and finish. Contact us today to receive a competitive quote and have our team help in supply of materials on time and to the specifications of your project.

Request Your ASTM A335 P11 Pipes Quote Today!