SAE 1020 is a low-carbon steel alloy characterized by low hardness and tensile strength with a typical Brinell hardness of 119 -235 and tensile strength of 410 Mpa -790 Mpa. Even with these reduced values, the SAE 1020 Steel Tube has the most crucial industrial benefits such as high ductility, machinability, and high weldability although the low carbon content renders it immune to induction or flame hardening. The material is mainly iron and carbon with small quantities of manganese, phosphorus and sulfur, the chemistry of the material is confirmed through heat analysis in ASTM A519 specifications. Although such low-alloyed seamless tubings are typically nitriding insensitive in their normal form, when the alloy is treated to carburizing, it is possible to produce surface hardness in excess of Rc65 without reducing the strength of cold-drawn tubing in the core. Available in hot-finished or cold-finished conditions and produced through strand or ingot casting, ASTM A519 Grade 1020 Steel Pipe is a staple in automated sectors and mechanical applications, where it is often oil-coated to enhance corrosion resistance.

AISI 1020 Tubes & Pipes, AISI 1020 Seamless Pipes and SAE 1020 Seamless Tubing Supplier in USA

USA Piping Solution is an ISO-certified manufacturer, supplier, and exporter of AISI 1020 Seamless Pipes and SAE 1020 Steel Tubes. Our commitment to excellence has earned us a significant domestic and international clientele. We have successfully supplied Carbon steel AISI 1020 to customers in USA & globally. We provide these pipes at competitive, economical prices. The AISI 1020 Seamless Pipes AND SAE 1020 Seamless Tubing are widely applied across numerous industries, including sugar, nuclear, marine, defense, and general fabrication.

Table of Contents

- Types of AISI 1020 Seamless Pipes

- SAE 1020 Steel Tube Specifications

- SAE 1020 Steel Pipes Chemical Composition

- AISI 1020 Seamless Pipe Mechanical Properties

- Equivalent grades of AISI 1020 Tubes & Pipes

- Dimensions Chart of SAE 1020 Tubes

- AISI 1020 Steel Seamless Pipe Testing

- Applications of AISI 1020 Tubes & Pipes

Types of AISI 1020 Seamless Pipes

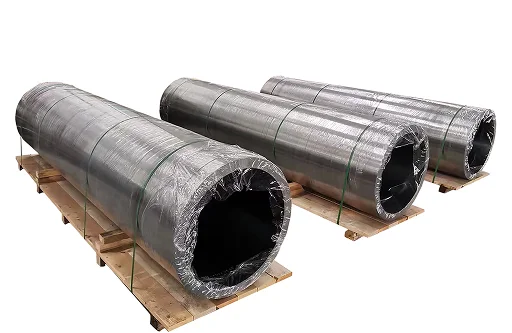

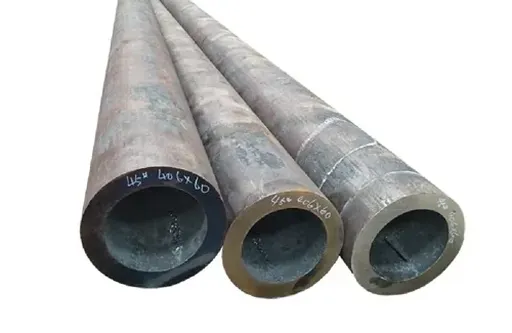

SAE 1020/20# carbon steel seamless pipe/seamless steel tube

SAE 1020 Cold Drawn Round Carbon Seamless Steel Pipe

cold drawn seamless tubes sae 1020

sae 1020 seamless pipe and tube

sae 1020 precision cold rolled seamless carbon steel tube

Carbon Steel Seamless Tube ASTM A106 SCH40 sae 1020

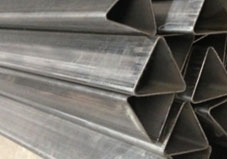

SAE 1020 Cold Drawn Triangle Seamless Steel Tube

SAE 1010/1020/1045 cold rolled seamless carbon steel tube

Standard SAE 1020 Seamless Carbon Steel Tube

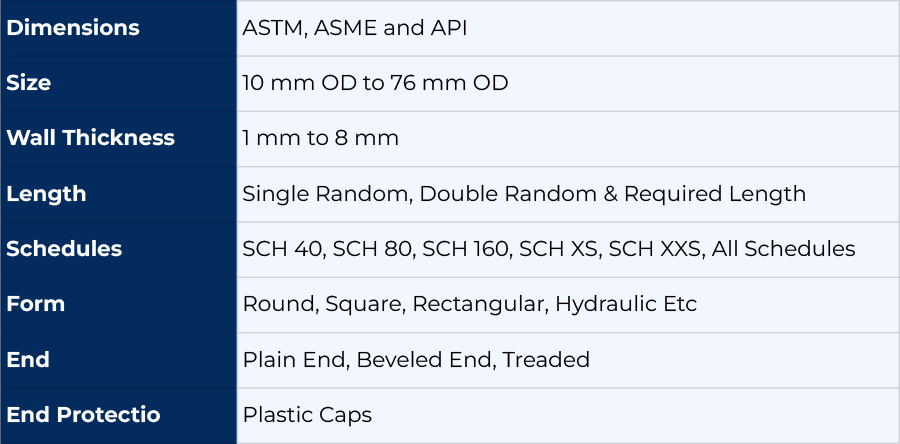

SAE 1020 Steel Tube Specifications

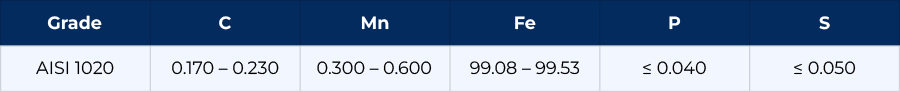

SAE 1020 Steel Pipes Chemical Composition

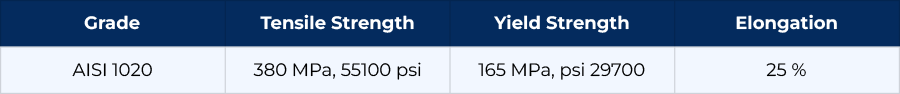

AISI 1020 Seamless Pipe Mechanical Properties

Equivalent grades of AISI 1020 Tubes & Pipes

| Grade | UNS |

|---|---|

| AISI 1020/ SAE 1020 | G10200 |

Dimensions Chart of SAE 1020 Tubes

AISI 1020 Steel Seamless Pipe Testing

To ensure dimensional accuracy, mechanical integrity, and compliance with international standards, AISI 1020 seamless pipes undergo the following testing and inspection procedures:

- Sulfide Stress Corrosion Cracking

- Reduction of Area

- Elongation

- Radiography Test

- Macro Test

- Hydrogen-Induced Cracking Test

- Pitting Resistance Test

- Spectro Analysis

- Flattening Test

- Flaring Test Bend Test

- Mechanical Testing Such as Tensile

- Micro Test

- Dye Penetrant Test

- Eddy Current Testing

- Impact Test

- Hardness Test

- Hydrostatic Test

- NACE TM 0177

- PMI Testing

- Intergranular Corrosion Test

- Ultra Sonic Test

This comprehensive inspection regime guarantees that AISI 1020 steel seamless pipes meet stringent quality, safety, and performance requirements for structural, mechanical, and pressure applications.

Applications of AISI 1020 Tubes & Pipes

- Case-Hardened Structural Applications

- Cold-Headed Bolts and Fasteners

- Axle Manufacturing

- General Engineering Components

- Machinery Parts

- Shafts and Camshafts

- Gudgeon Pins

- Ratchets

- Light-Duty Gears

- Spindles

Related Products

Request Your AISI 1020 Tubes Quote Today!

Frequently Asked Questions About AISI 1020 Tubes & Pipes

What is AISI 1020 material?

AISI 1020 is a common type of plain carbon steel. It provides a good balance of strength and flexibility and can be hardened using processes like carburizing.

What is the equivalent grade of AISI 1020?

AISI 1020 equivalent materials include SAE 1020, ASTM A36, AISI 1018, and international grades like EN3B or S20C. These are similar low-carbon steels used in general manufacturing, offering good workability and weldability.

What is the difference between AISI 1018 and 1020?

1020 steel is typically used for general parts like construction structures and mechanical components due to its balanced strength. 1018 steel is used for applications requiring higher strength and toughness, such as gears, shafts, and fasteners.

How much carbon is in AISI 1020 steel?

AISI 1020 is a low-carbon steel, containing only 0.17% – 0.23% carbon. This low carbon content gives the steel its notable ductility, malleability, and ease of welding.