Stainless Steel 304 Seamless Pipe & Tube Supplier in USA

Stainless Steel 304 Seamless Pipes & Tubes made of stainless steel are designed to work in harsh industrial conditions where high strength of pressure, resistance to temperatures and structural integrity is required. Manufactured with no welded joint, SS 304 seamless pipes have a consistent wall thickness and good mechanical run which makes it suitable in the pressure bearing systems and on-going service applications.

As the manufacturer of seamless pipes and tubes, USA Piping Solution offers a wide variety of diameters, wall thicknesses, and finishes to provide the same quality, complete traceability, and dependable delivery over the USA and the rest of the world.

What is Stainless Steel 304 Seamless Pipe?

A stainless steel 304 seamless pipe is produced through hot extrusion or cold drawing of solid stainless steel billets which produces a pipe without longitudinal weld seam. This smooth construction gives it a better load-bearing capacity, better fatigue properties, and better behavior in varying pressure and temperature environments.

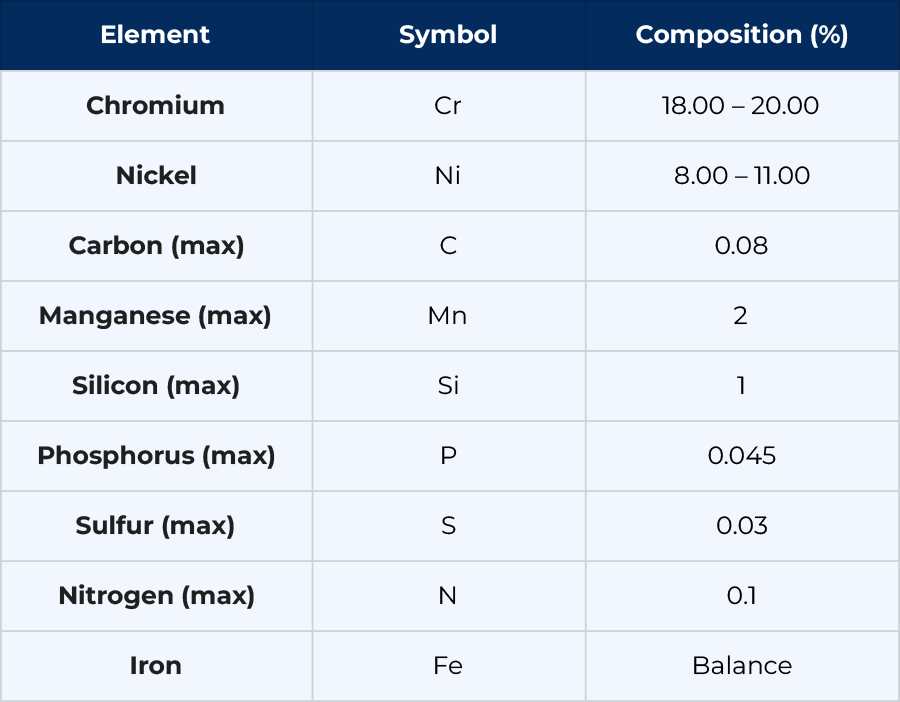

Being an austenitic stainless steel alloy, which is characterized by the presence of chromium and nickel, SS 304 seamless pipes are highly resistant to oxidation and overall corrosion and, therefore, are a safe bet to consider in terms of the general industrial and commercial use with minimum risks associated with the corrosion effect of the welding.

Looking to buy Stainless Steel Seamless Pipes and Tubes?

Check price of Stainless Steel 304L Seamless & Stainless Steel 316 Seamless Pipe

Table of Contents

- Stainless Steel 304 Seamless Pipe vs Welded Pipe

- ASTM A312 TP304 Seamless Pipe Specifications

- Chemical Composition of SS 304 Seamless Pipes

- Mechanical Properties of Stainless Steel 304 Seamless Tubes

- Manufacturing Process of SS 304 Seamless Pipes

- Applications of Stainless Steel 304 Seamless Pipes & Tubes

- Why Choose USA Piping Solution for SS 304 Seamless Pipes?

- Related Products

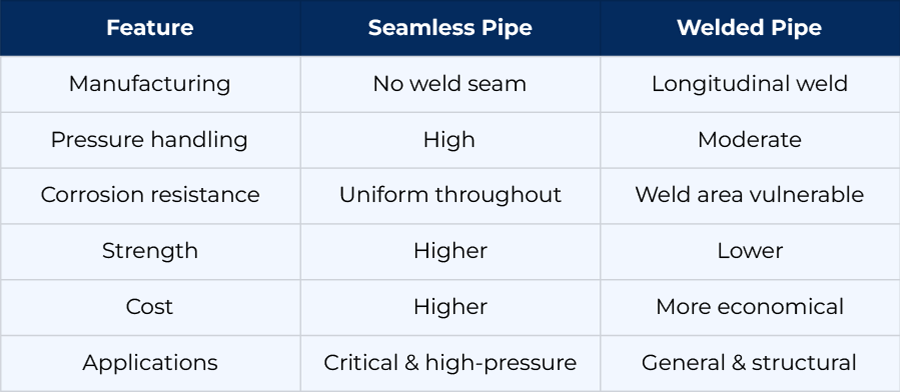

Stainless Steel 304 Seamless Pipe vs Welded Pipe

SS 304 seamless pipes are recommended for critical services, while welded pipes are suitable for non-critical and cost-sensitive applications.

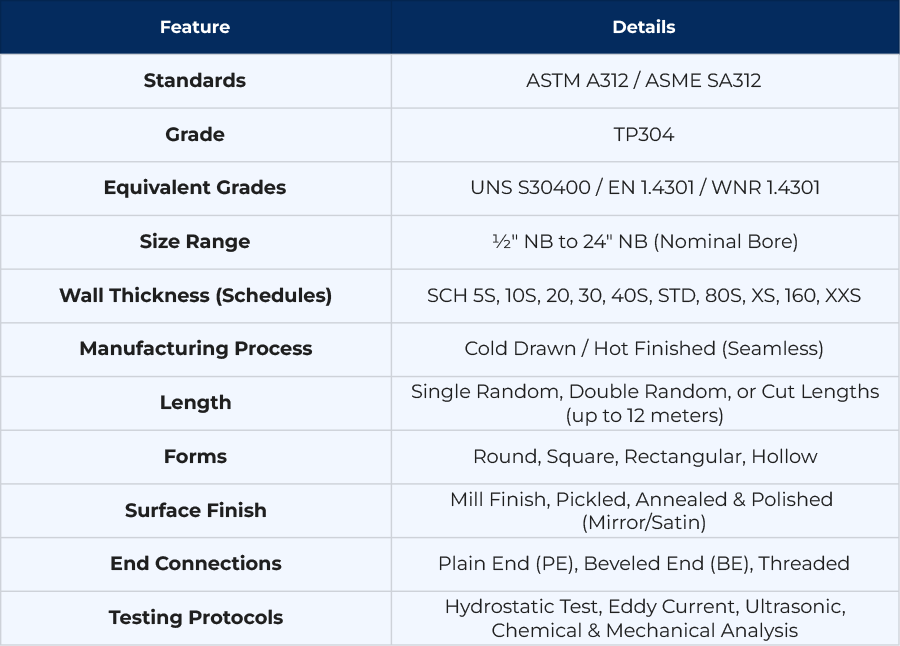

ASTM A312 TP304 Seamless Pipe Specifications

Chemical Composition of Stainless Steel 304 Seamless

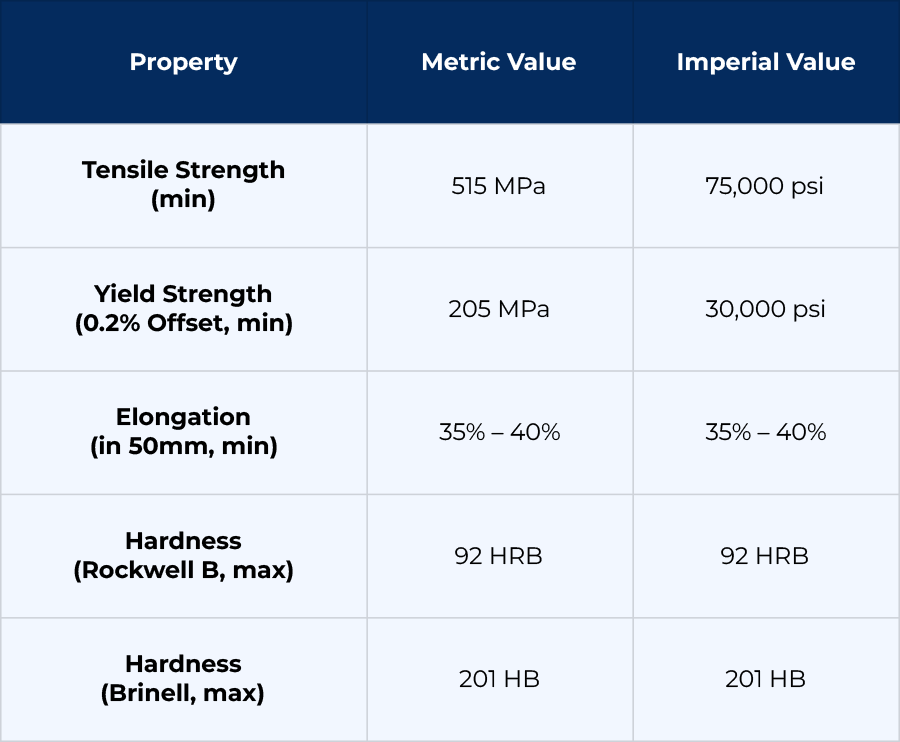

Mechanical Properties of Stainless Steel 304 Seamless

Manufacturing Process of SS 304 Seamless Pipes

The stainless steel seamless pipe manufacturing process ensures superior performance and consistency:

- Heating of stainless steel billets

- Piercing to create a hollow shell

- Hot rolling or cold drawing

- Solution annealing for corrosion resistance

- Pickling and surface finishing

- Hydro testing, NDT, PMI & dimensional inspection

Each stage is carefully controlled to comply with ASTM A312 and ASME SA312 standards.

Applications of Stainless Steel 304 Seamless Pipes & Tubes

Stainless Steel 304 seamless pipes and tubes are widely used in:

- Oil & gas transmission pipelines

- Chemical and petrochemical processing plants

- Heat exchangers and condensers

- Boilers and pressure vessels

- Power generation systems

- Pharmaceutical and food processing industries

- High-pressure fluid and gas piping systems

For applications requiring improved corrosion resistance after welding, low-carbon Stainless Steel 304L Seamless Pipes are typically recommended.

Why Choose USA Piping Solution for SS 304 Seamless Pipes?

- ASTM & ASME certified stainless steel materials

- Third-party inspection available (TPI, SGS, BV, etc.)

- Custom sizes, schedules & cut lengths

- Fast delivery across the USA

- Export experience across multiple industries

- ISO-certified quality management system

Related Products