The A694 F65 Carbon Steel Flanges of USA piping solution are made to be highly strong, durable and reliable in pressure and temperature demanding conditions. These forged flanges are made of high-yield carbon steel that provides them with high toughness, weldability, and crack and corrosion resistance. The flanges are designed to have the correct dimensions and a long service life and each flange is carefully engineered and tested according to ASME B16.5 and B16.47. We have an extensive range of our A694 Gr F65 flanges that are used in oil and gas pipelines, refineries, power plants, and offshore platforms. Being a dependable producer of carbon steel flanges in the USA, we also provide a variety of weld neck, blind, slip-on, and socket weld flanges designed to suit various requirements of the industry, which provide reliable working and quality in any project.

ASTM A694 F65 Flanges

High-quality ASTM A694 F65 Flanges manufactured for high-pressure piping systems in the USA

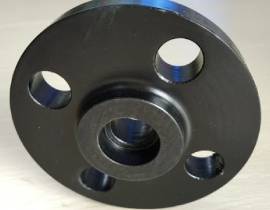

A694 Gr F65 Forged Flanges

A694 Gr F65 Forged Flanges with precision machining and superior yield strength for oil and gas pipelines

ASTM A694 F65 Material Specification

ASTM A694 F65 Material Specification showcasing chemical and mechanical properties of high-yield carbon steel

ASTM A694 F65 Flanges Manufacturer in USA, Supplying A694 F65 Flanges, ASME SA694 F65 Forged Flanges, and High Yield F65 Pipe Flanges to Global Industries

ASTM A694 F65 Carbon Steel Flanges are used in projects of pipeline and transmission in high-pressure situations where the high strength, weldability, and reliability of the product are vital. The F65 grade is manufactured using high-yield carbon steel and it is characterized by good mechanical properties which allow safe and efficient flow of oil, gas, steam, and water across pressurized systems. All the A694 F65 Forged Flange manufactured by USA Piping Solution is machined and inspected to the requirements of the ASME B16.5 and B16.47 in terms of dimensional and quality requirements.

We are a major ASME SA694 F65 Flanges Manufacturer in the USA with full capability to offer the complete variety of weld neck, blind, slip-on, socket weld flanges to be used in the refineries, petrochemical plants and power generation plants. Our A694 Grade F65 Pipe Flanges has a controlled chemical composition and refined grain structure that make it fatigue-resistant and to remain strong in an environment of fluctuating pressures.

Due to active innovation and process management, USA Piping Solution has created the image of a reliable supplier of ASTM A694 F65 Flanges to its customers throughout the USA and the global market to guarantee reliable performance and cost-efficiency over time in the harsh industrial setting.

Technical Specifications and Material Details of ASTM A694 F65 Flanges

| Category | Specification | Technical Notes |

|---|---|---|

| Standards | ASTM A694 / ASME SA694, ANSI / ASME B16.5, B16.47 A & B, EN 1092, DIN, BS4504, JIS, GOST | Compliant with international dimensional and pressure standards for high-performance flange connections |

| Pressure Rating & Classes | Class 150, 300, 600, 900, 1500, 2500 LB | Suitable for high-yield and high-pressure applications in energy and process industries |

| Manufacturing Process | Forged, Heat Treated, and Machined | Ensures enhanced strength, tight dimensional tolerance, and surface integrity |

| Material Grade | High Yield Carbon Steel ASTM A694 Grade F65 | Provides exceptional toughness, weldability, and resistance to stress and fatigue |

| Size Range (Nominal Bore) | ½″ (15 NB) to 48″ (1200 NB) / DN10 to DN5000 | Available in standard and custom dimensions as per project requirements |

| Bore Type Options | Standard, Equal, and Reducing Bore | Enables accurate alignment and consistent flow control |

| Flange Face Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Lap Joint (LJF), Tongue & Groove, Male-Female (SMF/LMF) | Compatible with a variety of gasket and sealing configurations |

| Connection Types | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Orifice, Long Weld Neck, Spectacle Blind | Designed for robust and leak-proof connections in critical pressure systems |

| Surface Finish | Smooth, Serrated, or Custom Machined Finish | Improves gasket grip and ensures long-term sealing reliability |

| Testing & Inspection | Ultrasonic, Radiography, Hydrostatic, and Dimensional Testing | Conducted under strict QA/QC protocols and third-party supervision |

| Certificates Provided | EN 10204 / 3.1B, Raw Material Test Certificate, Third-Party Inspection | Full traceability and verification for material quality and performance |

| Applicable Standards (JIS / EN) | JIS 5K–63K, EN 6Bar–40Bar | Aligns with global flange design and pressure norms |

| Manufacturing & Supply Regions | United States, Europe, Asia | Sourced and manufactured through globally approved mills ensuring consistent material quality |

| Applications | Oil & Gas, Petrochemical, Power Generation, Metallurgy, Marine, Construction | Used in high-pressure systems requiring yield strength and reliability |

| Quality Assurance | Heat Code Traceable, Fully Tested & Certified | Ensures compliance with ASTM and ASME standards for critical applications |

| Optional Customization | Drilling Patterns, Coating, Packaging, Surface Finish | Available upon request for tailored engineering solutions |

Types of ASTM A694 F65 Flanges Manufactured and Supplied by USA Piping Solution

A694 Carbon Steel F65 BLRF Flanges

SA 694 F65 Square Flanges

Carbon Steel ASTM A694 Grade F65 Spectacle Blind Flanges

A694 CS Gr F65 SORF Flanges

Carbon Steel ASME SA694 F65 Forged Flanges

ASTM A694 Grade F65 Reducing Flanges

SA694 F65 Socket Weld Flanges

ASME SA694 F65 SWRF Flanges

Carbon Steel ASME SA694 F65 Ring Type Joint Flanges

ASTM A694 Grade F65 High Hub Blind Flanges

Grade F65 Carbon Steel Orifice Flanges

ASTM A694 Gr F65 Screwed Flanges

ASME SA694 gr F65 Lapped joint Flanges

A694 Grade F65 Expander Flanges

ASTM A694 gr F65 Weld Neck Flanges Series A or B

A694 Gr F65 WNRF Flanges

Carbon Steel F65 RTJ Flanges

F65 Carbon Steel Threaded Flanges

ASTM A694 F65 Groove & Tongue Flanges

SA 694 F65 Nipo Flange

ASTM A694 Grade F65 Weldo Flange

ASTM A694 F65 Flanges Chemical Composition and Elemental Properties

| Grade | C | Mn | P | S | Si |

|---|---|---|---|---|---|

| F65 | ≤0.30 | ≤1.60 | ≤0.025 | ≤0.025 | 0.15-0.35 |

ANSI B16.5 ASTM A694 F65 Flanges Mechanical Properties and Strength Values

| ASTM A694 Grade | Yield Strength min. | Tensile Strength min. | Elongation min. | ||

|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | |

| F65 | 450 | 65 | 530 | 77 | 20 |

ASTM A694 F65 Flanges Weight Chart and Size Reference

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Industrial Applications and Service Areas of ASTM A694 F65 Flanges

- Widely used in oil and gas transmission lines for high-pressure flow systems

- Essential component in refineries and petrochemical plants for safe pipeline connectivity

- Applied in power generation and thermal plants for high-temperature piping assemblies

- Commonly installed in offshore and onshore drilling platforms for pressure control systems

- Used in chemical and fertilizer industries for corrosion-resistant flow handling

- Preferred in shipbuilding and marine engineering for strong welded joint performance

- Integrated into water treatment and desalination facilities for long-term reliability

- Employed in metallurgical and steel processing plants for durable fluid transport systems

- Utilized in infrastructure and construction piping projects requiring strength and endurance

- Trusted by EPC contractors and industrial fabricators for customized flange solutions

Key Features and Performance Advantages of ASTM A694 F65 Flanges

Features & Advantages

- Manufactured from high-yield carbon steel ensuring superior tensile and yield strength

- Offers excellent pressure resistance suitable for critical pipeline systems

- Provides high impact toughness even under fluctuating temperature and stress conditions

- Ensures tight dimensional tolerance through precision forging and machining processes

- Delivers enhanced weldability and crack-resistant joint performance

- Compatible with multiple standards including ASME B16.5 and B16.47

- Available in weld neck, blind, slip-on, socket weld, and threaded types

- Features corrosion-resistant properties suitable for oil, gas, and marine environments

- Designed for long service life and reduced maintenance downtime

- Fully tested and certified with traceable documentation as per ASTM and EN requirements

Frequently Asked Questions (FAQs) on ASTM A694 F65 Flanges

What is ASTM A694 Grade F65 material?

ASTM A694 Grade F65 is a high-grade carbon steel which is made into fittings and flanges used in high pressure pipelines. It is very tough, weldable, and reliable in the work of oil, gas, and petrochemicals.

What is the difference between ASTM A694 F65 and A105?

ASTM A694 Grade F65 is a high-grade carbon steel which is made into fittings and flanges used in high pressure pipelines. It is very tough, weldable, and reliable in the work of oil, gas, and petrochemicals.

What is the ASTM standard for carbon steel flanges?

The carbon steel flanges standard of ASTM encompasses ASTM A105, ASTM A350 and ASTM A694. A694 is one of them dealing with high-yield strength flanges in high-pressure pipeline systems.

What is ASTM A694?

ASTM A694 is a standard specification of carbon and alloy steel forgings applicable to high pressure systems of piping particularly in the transmission of oil and gas, with grades ranging between F42 and F70.

What is the chemical composition of ASTM A694 F65?

ASTM A694 F65 primarily contains Carbon, Manganese, Phosphorus, Sulfur, Silicon, and small quantities of Chromium, Nickel, and Molybdenum to enhance strength and corrosion resistance.

What is the equivalent material for ASTM A694 F65?

The closest equivalent materials include EN 10222-2 Grade P355QH1, DIN 1.0566, and ISO 2604-2 Grade 355-490. These materials offer similar yield strength and pressure performance characteristics suitable for forged components.