ASTM A423 Grade

ASTM A423 is a specialized low-alloy carbon steel grade, which is mainly used in atmospheric corrosion resistance. It is also called Corten Steel and is unique because it develops a stable, oxidic, surface layer also called a patina when left in the natural weather conditions. This patina functions as an insoluble protective coating, and greatly increases the life of the piping in hostile atmospheres or helps to minimize maintenance in harsh conditions.

Looking to buy Alloy Steel Seamless Pipes & Tubes? Contact us for a custom quote today!

ASTM A423 Grade 1 Corten Steel Seamless Tube, Corten Steel ASTM A423 Gr 1 Welded Pipe, A423 GR A ERW Tube & ASTM A 423 Gr 1 Supplier in USA

USA Piping Solution is a premier manufacturer, stockist and global exporter of high-quality Corten Steel ASTM A423 Grade 1 tubes, offering both seamless and welded configurations. Specifically engineered for environments with highly corrosive atmospheres.

To meet the diverse needs of global infrastructure, these tubes are available in various geometries, including round, square, rectangular, hydraulic, and honed profiles. They can be customized in terms of length (single random, double random, or cut-to-length) and end finishes, such as plain or beveled. As a trusted dealer and supplier adhering to international standards like ASME, AISI, JIS, and DIN, We ensure every product undergoes rigorous quality assurance. This includes specialized evaluations such as Positive Material Identification (PMI), intergranular corrosion testing, pitting resistance analysis, and flattening/flaring tests, providing buyers with reliable, industrial-grade solutions at competitive rates.

Looking to buy Corten Steel Pipes & Tubes?

Check price of ASTM A106 Grade B Seamless Pipe & ASTM A847 Tubes

Table of Contents

- Types of ASME SA423 Tubes

- ASTM A423 Tube Specifications

- ASTM A423 Grade 1 Tube Equivalent Grades

- Mechanical Properties of ASTM A423 Gr 1 Corten Steel Seamless Pipes

- Chemical Composition of ASTM A423 Grade 1 Seamless Pipes

- Size range of ASTM A423 Tubes

- Application on ASTM A423 Corten Steel Pipes

- How to Choose the Right ASTM A423 Tube for Your Needs

- Related Products

- Frequently Asked Questions About ASTM A423 Gr 1 Tubes

Types of ASME SA423 Tubes

Corten Steel ASME SA423 pipe

- OD: ½ – 16 inch

- Grade: gr 1 and 3

- Thickness: 2 to 100mm

ASTM A423 Grade 1 tube

- Square

- Round

- Rectangle

ASTM A210 / ASME SA 210 Grade A1/C:

- Square

- Round

- Rectangle

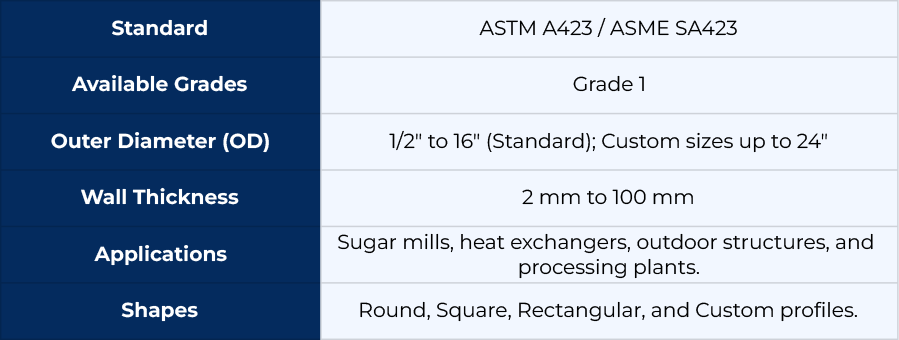

ASTM A423 Tube Specifications

For high-quality and versatile Corten steel ASTM A423 tubes for structural applications, request a quote today.

ASTM A423 Grade 1 Tube Equivalent Grades

Mechanical Properties of ASTM A423 Gr 1 Corten Steel Seamless Pipes

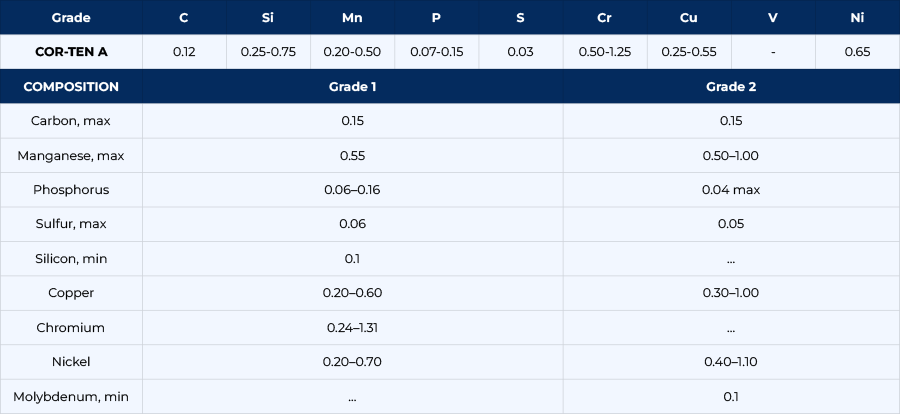

Chemical Composition of ASTM A423 Grade 1 Seamless Pipes

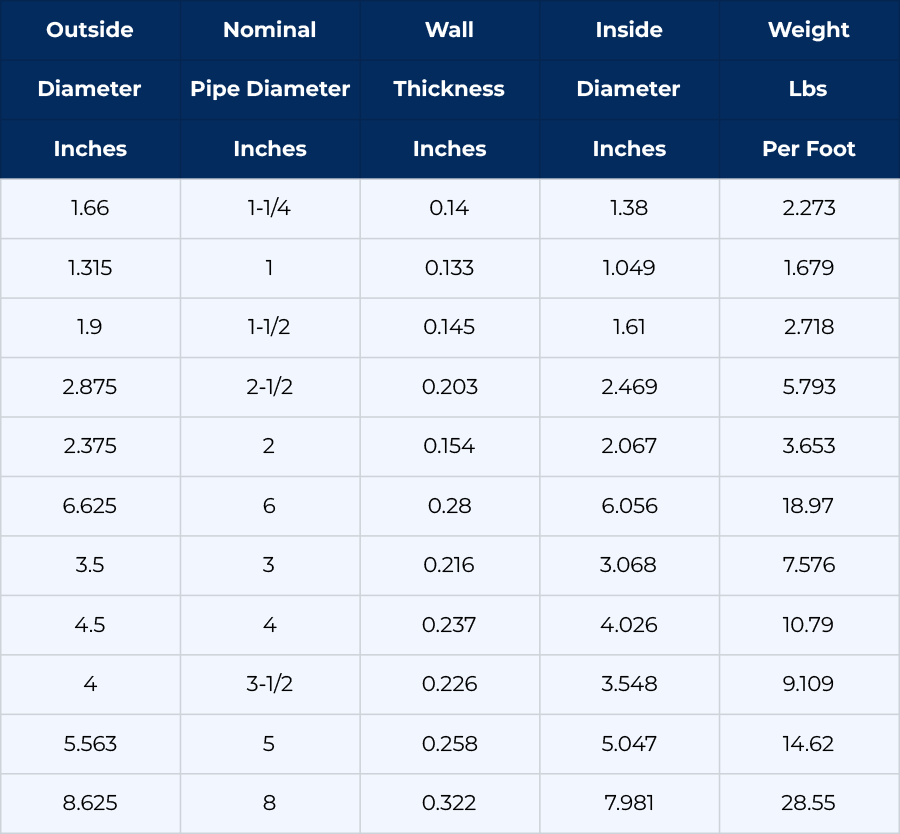

Size range of ASTM A423 Tubes

Request Your A423 Grade 1 Tube Quote Today!

Application on ASTM A423 Corten Steel Pipes

ASTM A423 Grade 1 are the preferred choice for sectors where atmospheric corrosion and high-temperature oxidation are constant threats. Because of their unique "self-healing" patina layer, these pipes provide long-term structural integrity in the following environments:

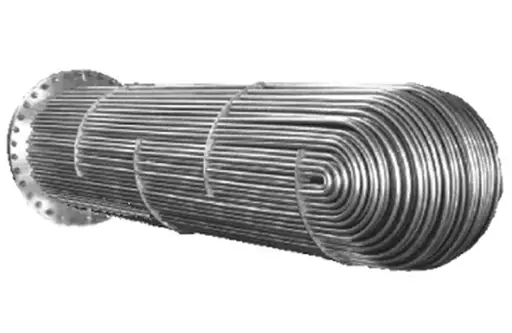

- Power Generation: Widely used in air preheaters and economizers where flue gases cause dew-point corrosion.

- Heat Exchangers & Condensers: Ideal for heat transfer equipment that operates under fluctuating thermal cycles.

- Gas Processing: Utilized in the transport and treatment of natural gas where external weather resistance is mandatory.

- Petrochemicals & Specialty Chemicals: Reliable piping for the transport of volatile compounds and chemical refining processes.

- Pulp and Paper Industry: Resists the aggressive humidity and chemical vapors found in bleaching and pulping units.

- Sugar Mills: Often used in juice heaters and evaporator tubes due to its resistance to organic acids.

- Pharmaceutical Equipment: Employed in the construction of processing vessels and sterilized piping systems.

- Sea Water Equipment: Though not for submerged use, it is excellent for coastal infrastructure exposed to salt-laden air.

- Off-Shore Oil Drilling: Used in top-side structures and piping on rigs where salt spray would quickly degrade standard carbon steel.

How to Choose the Right ASTM A423 Tube for Your Needs

- Begin by understanding the specific application for your project and identifying the material that best suits your requirements. Consider factors such as the operating temperature and environmental conditions involved.

- Next, determine the correct size and dimensions required for your ASTM A423 tube.

- Evaluate whether seamless or ERW pipes are a better fit based on your application needs and budget.

The right ASTM A423 tube should meet all relevant standards and specifications.

Related Products

Request Your A423 Grade 1 Tube Quote Today!

Frequently Asked Questions About ASTM A423 Gr 1 Tubes

What is the difference between ASTM A423 Grade 1 and Grade 3?

ASTM A423 Grade 3 contains all the elements found in Grade 1, but with trace amounts of Molybdenum (Mo) and Antimony (Sb) in its chemical composition. Additionally, ASTM A423 Grade 1 has higher tensile and yield strengths compared to Grade 3.

What is the primary purpose of ASTM A423 tubes?

ASTM A423 tubes are primarily used for corrosive applications. They are commonly found in industries such as sugar mills and various processing units due to their durability and resistance to weathering and corrosion.

Which certifications should I request when purchasing ASTM A423 Grade 1 pipes?

When purchasing ASTM A423 Grade 1 pipes, you should request mill test certificates (MTC) and certification of compliance with the ASTM A423 specification. The MTC will provide critical information about the chemical composition, mechanical properties, and testing of the pipes. Ensuring compliance with the specification guarantees the pipe has all the required properties for your project.

How much does the ASME SA423 tube cost?

The cost of ASME SA423 pipes can vary depending on the supplier, as each may have different pricing strategies based on internal costs and profit margins. Pricing is also influenced by factors such as the quantity ordered, market conditions, required customization, and delivery location.