USA Piping Solution is one of the suppliers of ASTM A335 P91 Pipes. It is a special ASTM A335 P91 Alloy Steel Seamless Pipe, which is engineered to serve in the harsh high temperature operating conditions and high corrosion resistance. Being categorized in the type of Creep Strength Enhanced Ferritic (CSEF) steel, the special chemistry of the product comprises high amounts of 8.00%-9.50% Chromium and 0.85%-1.05% Molybdenum. The material offers a high creep strength, oxidation resistance and long-term metallurgical stability even at extremely high temperatures thus with respect to other conventional carbon steels this material renders a better performance.

.webp)

ASTM A335 P91 Chrome Moly Alloy Pipes for High Temperature

ASTM A335 P91 Seamless Pipe has excellent mechanical properties with the lowest tensile strength of 415 Mpa and the lowest yield strength of 205 Mpa. To a large extent, this strength and durability is attributed to the fact that this process has involved a very tight heat treatment: the metal is normalized at 1050 degree C, air-cooled at 200 degree C, and then tempered at 760 degree C. This is essential in obtaining the high creep strength, non-deteriorating nature of the UNS K21590 material coupled with the long term stability. The alloy is commonly reduced to 9 percent chrome and 1 percent molybdenum as well as vanadium.

This is due to the special blend of high toughness, wear resistance and high weldability that makes ASTM A335 P91 Chrome Moly Alloy Pipe essential in high-stress serious systems. It is currently extensively used in pipelines of oil and gas, power plants (particularly ultra-supercritical and steam lines boilers), refineries, and petrochemical plants where thinner component thickness and extended service life are imperative.

The USA Piping Solution holds a large stock of the ASME SA335 Grade P91 Pipe, of Type 2, which is built to the advanced industry directions. We deliver every type of component, including high-energy pipes and fittings, as well as valves and flanges all of high quality. It is also made in several international standards, such as GOST 550-75, ASTM A213, ASME SA213, EN 10216-2 and NBR 5603. We will provide quality ASTM A335 P91 Pipes and tailor-made Alloy Steel Seamless Pipes.

Table of Contents

- ASTM A335 P91 Seamless Pipe Specifications

- Chemical Composition of ASTM A335 P91 Chrome Moly Alloy Pipe

- Mechanical Properties of ASME SA335 Grade P91 Pipe

- Equivalent Grades for ASTM A335 P91 Pipes

- Heat Treatment for ASTM A335 P91 Seamless Pipe

- Dimensions of ASTM A335 P91 Alloy Steel Seamless Pipe

- ASTM A335 P91 Pipes Weight Chart

- Types and Forms of ASTM A335 P91 Pipes

- Applications of ASTM A335 P91 Alloy Steel Seamless Pipes

- ASTM A335 P91 Pipe Price in USA

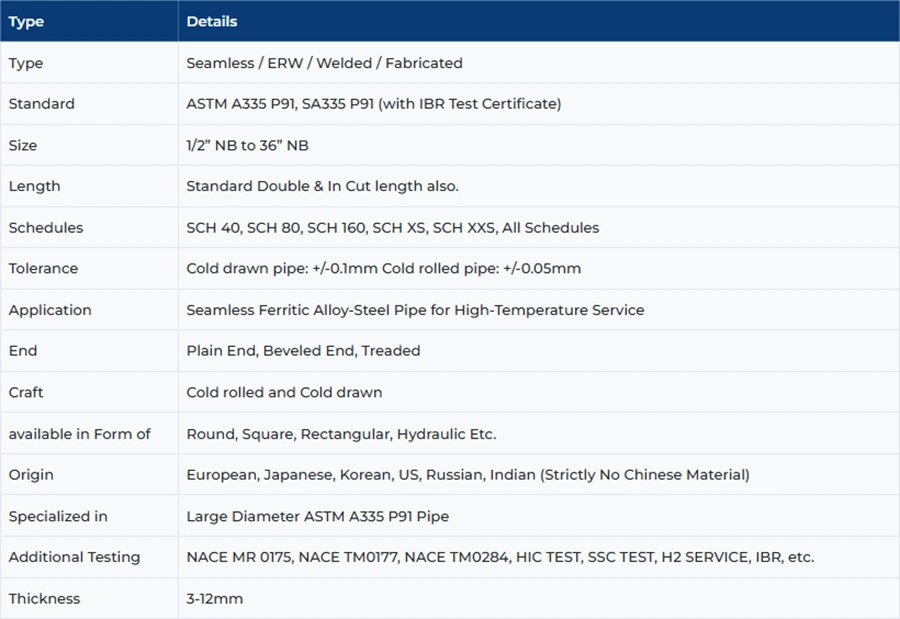

ASTM A335 P91 Seamless Pipe Specifications

This table outlines the primary standards and classifications for the advanced P91 grade pipe.

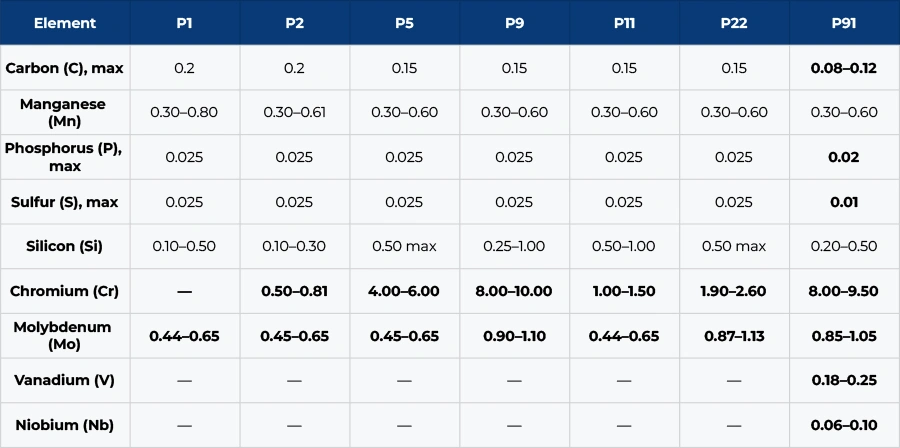

Chemical Composition of ASTM A335 P91 Chrome Moly Alloy Pipe

The precise composition, including Vanadium and Niobium (or Columbium), is critical for P91's exceptional creep strength and stability.

Mechanical Properties of ASME SA335 Grade P91 Pipe

The P91 grade exhibits superior strength characteristics compared to lower-alloy Cr−Mo steels due to its heat treatment.

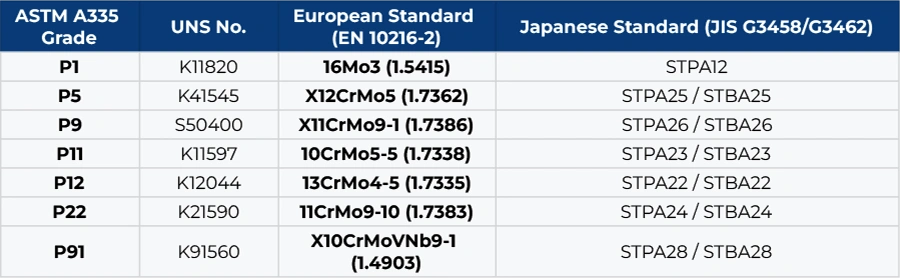

Equivalent Grades for ASTM A335 P91 Pipes

Heat Treatment for ASTM A335 P91 Seamless Pipe

| Heat Treatment Method | Temperature Range |

|---|---|

| Normalizing | 1040∘C to 1080∘C (1900∘F to 1975∘F) - Air cool or accelerated cooling |

| Tempering | 730∘C to 780∘C (1350∘F to 1430∘F) - Must be held for a minimum of 1 hour |

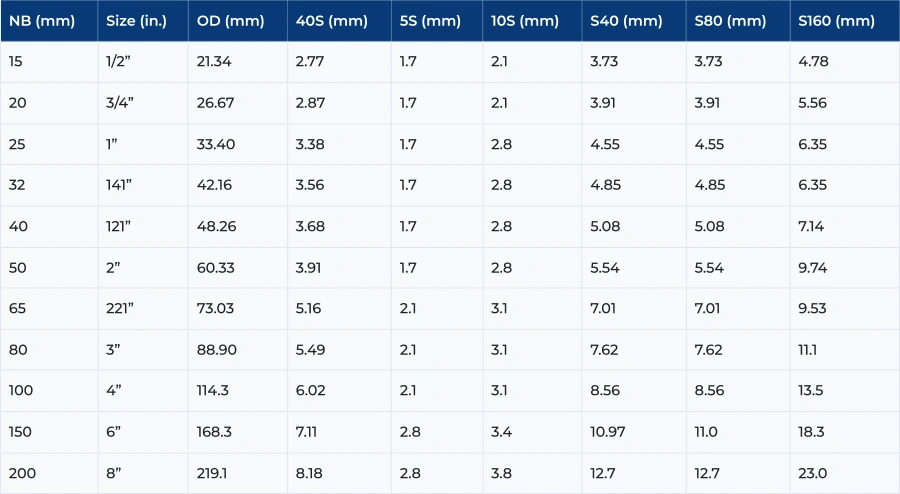

Dimensions of ASTM A335 P91 Alloy Steel Seamless Pipe

This chart provides the Outer Diameter (OD) and corresponding Wall Thickness (WT) in millimeters for various Nominal Bore (NB) sizes and Schedules.

Note: WT columns represent approximate thickness for the corresponding Schedule (e.g., Sch 40S, Sch S160).

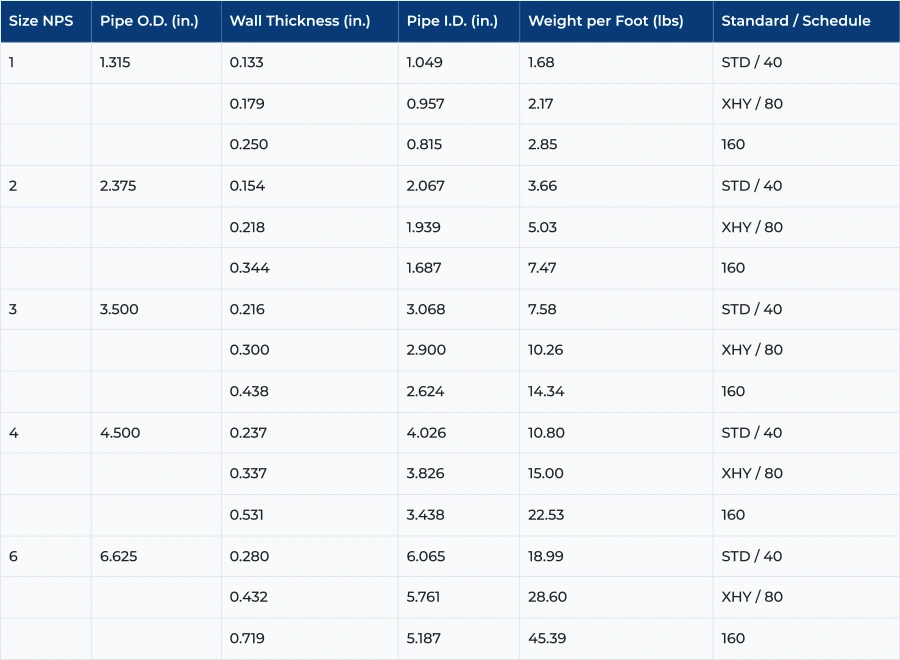

ASTM A335 P91 Pipes Weight Chart

This chart provides dimensional data and calculated weights for standard P91 pipe sizes, which is generally consistent across all ASTM A335 grades. Note that due to the higher density of alloy steel, actual weight may slightly vary from carbon steel calculations, but these values represent the nominal density.

Applications of ASTM A335 P91 Alloy Steel Seamless Pipes

The exceptional high-temperature performance and stability of ASTM A335 P91 Seamless Pipes make them critical for modern, high-efficiency systems.

- Supercritical and ultra-supercritical power generation: Used in steam headers, main steam lines, and reheater circuits where temperatures exceed 600°C.

- High-pressure boilers and heat recovery systems: Valued for its high creep rupture strength under continuous thermal cycling.

- Petrochemical refining: Applied in reactors, steam reformers, and hydrogen service lines exposed to aggressive environments.

- Nuclear plant piping: Suitable for high-temperature nuclear coolant systems due to enhanced oxidation resistance.

- Process piping in oil and gas: Ideal for high-stress environments where mechanical integrity is essential over extended operating lifespans.

Related Products

Find the perfect fit for your project. Our complete catalog details the applications and specifications of all Alloy Steel Pipes & Tubes.

ASTM A335 P91 Pipe Price in USA

| Size (NB) | MSL Make (USD/Ton) | ISMT Make (USD/Ton) | JSL Make (USD/Ton) |

|---|---|---|---|

| 1/2" | $4,264.71 | $4,257.35 | $4,272.06 |

| 3/4" | $4,044.12 | $4,036.76 | $4,051.47 |

| 1" | $3,897.06 | $3,889.71 | $3,904.41 |

| 1.25" | $3,852.94 | $3,845.59 | $3,860.29 |

| 1.5" | $3,750.00 | $3,742.65 | $3,757.35 |

Quick Note: These prices cover SCH 40, 60, 80, & XS pipe specifications. Remember, your final price in the USA will include shipping, duties, and local costs.

Looking for bulk orders or custom solutions? Reach out to USA Piping Solution for a firm, all-in quote delivered to your project site anywhere in the USA.

Request Your ASTM A335 P91 Pipes Quote Today!Frequently Asked Questions About A335 Grade P91 Chrome Moly Alloy Pipe

What is ASTM A335 P91 material?

ASTM A335 P91 is a high-end seamless ferritic chrome-moly alloy steel pipe manufactured to be used in high temperature. It is called 9Cr1Mo steel and it consists of 8.00%-9.50% Chromium and 0.85%-1.05% Molybdenum. It is a Creep Strength Enhanced Ferritic (CSEF) steel, which has better creep resistance and high strength performance in the case of a critical application in a high pressure and high-heat environment with high pressure without wear even after long durations.

What is the hardness of ASTM A335 P91?

The hardness of the ASTM A335 P91 material is highly restricted in nature to allow maximum performance. The pipe will not be more than 250 HB (Brinell Hardness). The material can be continuously used in a temperature up to approximately 650 o C (1202 o F) at the wall temperature typically found in the steam boilers and pressure vessels.

What is ASTM A335 P9 pipe made of?

ASTM A335/SA335 Grade P9 is another seamless ferritic alloy-steel pipe that is applied in high temperatures. It is mostly made up of Chromium and Molybdenum with P9 usually having 8.00%–10.00% Chromium and 0.90%–1.10% Molybdenum. P9 is applied in such environments to carry water, oil, and natural gas, which is of significant precedent to the high-performance P91 type.