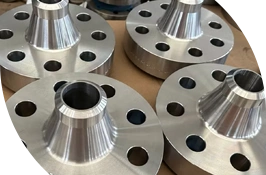

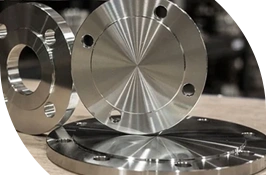

USA Piping Solution is a U.S. based carbon steel flanges manufacturer that offers project-ready carbon steel pipe flanges for high pressure and high temperature service applications.The flanges made of carbon steel are popular in the industrial piping systems because they are very strong, durable and cost effective. These flanges are made of high quality carbon steel and can withstand high pressure and temperature thereby being suitable in an oil and gas industry, power plants and petrochemicals industries. We have plenty of varieties of flanges at USA Piping Solution which is a reputable brand in the carbon steel flanges industry and deals with carbon steel plate flanges, carbon steel slip-on flanges, and carbon steel forged flanges. We sell products between 1/2 inch and 48 inches and pressure classes of 150#, 300# and 600 #, in accordance with standard specifications such as ASTM A105 Carbon Steel Flanges, ASTM A350 LF2 flanges, and ASME B16.5.

Being one of the manufacturers of carbon steel flanges in the United States, we are proud to offer flanges that are of good performance and are also durable. CS flanges have been known to provide extreme conditions and possess great mechanical properties including tensile and impact resistance. Flanges such as the carbon steel forged flanges are engineered to be used in heavy-duty applications which have high structural integrity. On the other hand, carbon steel slip-on flanges are used when the pressure is lower and therefore are easily installed. The carbon and manganese alloy of these flanges make them tough and corrosive so that they have a long life in even the most demanding conditions.

USA Piping Solution is aware of precision and reliability. This is why our carbon steel flanges are strictly checked in terms of quality to comply with such standards as ASME B16.47 and MSS SP-44. You may require lightweight carbon steel plate flanges daily use or you may require hardy forged ones when on the high stress systems, we offer you the solution in accordance with your needs. USA Piping Solutions has a high level of concentration in terms of quality and customer satisfaction and this has made it remain the best manufacturer of carbon steel flanges to be trusted. Go with us to have superior quality flanges that perform and be economical.

Specifications for Carbon Steel Flanges

| Category | Specification / Range | Buyer Notes (Installation, Compliance, Availability) |

|---|---|---|

| Materials / Grades | ASTM A105, ASTM A350 LF2 (LTCS), ASTM A694 (F42, F46, F52, F60, F65, F70), ASTM A36, ASTM A516 Gr. 70/60 |

Covers mainstream carbon steel flange needs from ambient to low-temp and high-yield pipeline service. MTRs available (EN 10204 3.1). |

| Dimensional Standards | ANSI/ASME B16.5, ASME B16.47 (Series A & B), MSS SP-44, ASA, API-605 (legacy → B16.47), AWWA, custom drawings |

U.S. projects typically call out ASME; API-605 references map to B16.47. Custom “carbon steel flange dimensions” supported on request. |

| Governing Standards | ASTM, ASME (ASME Flanges), ANSI (ANSI Flanges), DIN, EN, BS |

Cross-standard supply available; we prioritize ASME/ANSI for U.S. code compliance. |

| Size Range | 1/2" NB to 48" NB |

Common stock: 1/2"–24" (B16.5); 26"–48" (B16.47). Larger/bespoke sizes via forged carbon steel flanges program. |

| Pressure Class / Rating | Class 150, 300, 600, 900, 1500, 2500; DIN PN 6/10/16/25/40 |

Pressure–temperature ratings per ASME. We can advise conversion between ASME Classes and DIN PN for mixed specs. |

| Types | carbon steel weld neck flange, carbon steel slip-on flange, carbon steel blind flange, socket weld, threaded, lap joint, orifice, spectacle blinds |

WN for cyclic/high-pressure lines; SO for lower-pressure utility; BL for line isolation. Full set of carbon steel pipe flanges for plant standardization. |

| Facing Options | RF (Raised Face), RTJ (Ring Type Joint), FF (Flat Face) |

RTJ is favored in high-pressure services (Class ≥600); RF is the U.S. default for most Class 150–300 systems. |

| Bore / Schedule | Matches pipe Sch 10–XXS, custom bores and drilling |

We machine to your piping schedule and gasket compatibility ask for a carbon steel flange dimensions sheet. |

| Manufacturing Route | Forged, plate (per drawing) |

Forged carbon steel flanges recommended for shock/cyclic duty and critical services. |

| Coatings / Finishes | Black oxide, light oil, hot-dip galvanizing, epoxy/PTFE, FBE (project-based) |

Corrosion protection tailored to service and storage; coating certs on request. |

| Testing & Docs | MTRs, PMI, NDT (UT/MT/PT), hydrotest (when specified), heat-number traceability |

Standard QA pack for U.S. compliance; additional project dossiers available. |

| Compliance Add-Ons | Buy American / BAA / DFARS (when specified); country of origin traceability |

Provided for U.S. federal or defense-linked projects—confirm at RFQ stage. |

| Gasket Compatibility | Spiral wound, RTJ (R/RX/BX), sheet gaskets per ASME |

We can kit gaskets/bolting with flanges for a single-line item per flange size/class. |

Carbon Steel Flange Price List and Stock Check (USA).

Request the latest carbon steel flange pricing, lead times, and stock status. Email sales@usapipingsolution.com with your size, class, material (e.g., ASTM A105, A350 LF2, A694), facing (RF/RTJ/FF), and quantity for a fast quote and nationwide delivery.

Carbon Steel Flanges in Stock

Carbon Steel Blind Flanges

CS Blind Flanges Carbon Steel BLRF Flanges

ANSI B16.5 CS Blind Flange

Carbon Steel Threaded Flanges

CS Threaded Flanges

ANSI B16.5 CS Threaded Flange

CS Socket weld Flanges

CS SWRF Flanges

ANSI B16.5 CS Socket weld Flanges

Carbon Steel Lap Joint Flanges

CS Lap Joint Flanges

ANSI B16.5 CS Lapped Joint Flange

Carbon Steel RTJ Flanges

CS RTJ Flanges

ANSI B16.5 CS RTJ Flange

Carbon Steel Orifice Flanges

CS Orifice Flanges

ANSI B16.36 CS Orifice Flange

Carbon Steel Long Weld Neck

Flanges

CS Long Weld Neck Flanges

ANSI B16.5 CS Long Weld Neck Flange

CS Spectacle Blind Flanges

Carbon Steel Spectacle Blind Flange

ANSI B16.5 CS Spectacle Blind Flange

Carbon Steel Forged Flanges

CS Forged Flanges

ANSI B16.5 CS Forged Flange

Carbon Steel Plate Flanges

CS Plate Flanges

ANSI B16.5 CS Plate Flange

CS Slip on Flange Mechanical Properties

| Yield Strength min. | Tensile Strength min. | Reduction of Area, min. | Elongation min. | Hardness | ||||

|---|---|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | % | % | % | HBW |

| 250 | 36 | 485 | 70 | 30 | 22 | 137-187 | ||

Carbon Steel Pipe Flange Physical Properties

| Density (lb / cu. in.) | 0.284 |

|---|---|

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.107 |

| Modulus of Elasticity Torsion | 11 |

| Specific Gravity | 7.9 |

| Thermal Conductivity | 360 |

| Melting Point (Deg F) | 2740 |

| Modulus of Elasticity Tension | 30 |

| Mean Coeff Thermal Expansion | 6.7 |

Carbon Steel Lap Joint Flange Chemical Composition

| Elements | Composition, % |

|---|---|

| Phosphorus [P] | ≤0.35 |

| Carbon [C] | ≤0.35 |

| Sulfur [S] | ≤0.40 |

| Manganese [Mn] | 0.60-1.05 |

| Copper [Cu] | ≤0.40 |

| Silicon [Si] | 0.10-0.35 |

| Chromium [Cr] | ≤0.30 |

| Nickel [Ni] | ≤0.40 |

| Vanadium [V] | ≤0.08 |

| Molybdenum [Mo] | ≤0.12 |

Carbon Steel Flanges Industrial Applications

- Sea Water Equipment

- Power Generation Industry

- Oil and Gas Industry

- Food Industry

- Pharmaceuticals

- Chemical Industry

- Petrochemical Industry

- Heavy Pressure Applications

- Heat Exchangers

Carbon Steel Flanges Dimensions

| Nominal Pipe Size | Thickness of Flange (B) | OD of Flange (D) | Dia of Bolt Circle (K) | Dia of Bolt Holes (L) | Dia of Raised Face (G) | Dia of Bolt (inches) | Approx Weight (kg) | No of Bolt Holes |

|---|---|---|---|---|---|---|---|---|

| 1-1/4 | 15.7 | 117.3 | 88.9 | 15.7 | 63.5 | 1/2 | 1 | 4 |

| 1/2 | 11.2 | 88.9 | 60.5 | 15.7 | 35.1 | 1/2 | 0.5 | 4 |

| 1-1/2 | 17.5 | 127 | 98.6 | 15.7 | 73.2 | 1/2 | 2 | 4 |

| 3/4 | 12.7 | 98.6 | 69.9 | 15.7 | 42.9 | 1/2 | 1 | 4 |

| 2-1/2 | 22.4 | 177.8 | 139.7 | 19.1 | 104.6 | 5/8 | 3 | 4 |

| 1 | 14.2 | 108 | 79.2 | 15.7 | 50.8 | 1/2 | 1 | 4 |

| 3-1/2 | 23.9 | 215.9 | 177.8 | 19.1 | 139.7 | 5/8 | 6 | 8 |

| 2 | 19.1 | 152.4 | 120.7 | 19.1 | 91.9 | 5/8 | 2 | 4 |

| 4 | 23.9 | 228.6 | 190.5 | 19.1 | 157.2 | 5/8 | 8 | 8 |

| 3 | 23.9 | 190.5 | 152.4 | 19.1 | 127 | 5/8 | 4 | 4 |

| 6 | 25.4 | 279.4 | 241.3 | 22.4 | 215.9 | 3/4 | 12 | 8 |

| 5 | 23.9 | 254 | 215.9 | 22.4 | 185.7 | 3/4 | 9 | 8 |

| 12 | 31.8 | 482.6 | 431.8 | 25.4 | 381 | 7/8 | 50 | 12 |

| 8 | 28.4 | 342.9 | 298.5 | 22.4 | 269.7 | 3/4 | 20 | 8 |

| 14 | 35.1 | 533.4 | 476.3 | 28.4 | 412.8 | 1 | 64 | 12 |

| 10 | 30.2 | 406.4 | 362 | 25.4 | 323.9 | 7/8 | 32 | 12 |

| 18 | 39.6 | 635 | 577.9 | 31.8 | 533.4 | 1-1/8 | 100 | 16 |

| 16 | 36.6 | 596.9 | 539.8 | 28.4 | 469.9 | 1 | 82 | 16 |

| 24 | 47.8 | 812.8 | 749.3 | 35.1 | 692.2 | 1-1/4 | 195 | 20 |

| 20 | 42.9 | 698.5 | 635 | 31.8 | 584.2 | 1-1/8 | 129 | 20 |

Blind Flange Carbon Steel Schedule Chart

| Pipe Size | 300 # | 150 # | 1500 # | 600 # | 2500 # | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1" | 4 | 3 | 3 | 3 | 2 | 2 | 9 | 8 | 8 | 4 | 4 | 4 | 12 | 11 | 11 |

| 1/2" | 2 | 1 | 1 | 2 | 1 | 1 | 5 | 4 | 4 | 2 | 2 | 2 | 7 | 7 | 7 |

| 1 1/2" | 7 | 6 | 6 | 4 | 3 | 3 | 13 | 12 | 13 | 8 | 7 | 8 | 25 | 22 | 23 |

| 3/4" | 3 | 3 | 3 | 2 | 2 | 2 | 6 | 5 | 6 | 4 | 3 | 3 | 8 | 8 | 8 |

| 2 1/2" | 12 | 10 | 12 | 8 | 7 | 7 | 36 | 36 | 35 | 18 | 13 | 15 | 52 | 55 | 56 |

| 2" | 9 | 7 | 8 | 6 | 5 | 5 | 25 | 25 | 25 | 12 | 9 | 10 | 42 | 37 | 39 |

| 4" | 25 | 22 | 27 | 15 | 13 | 17 | 73 | 73 | 73 | 42 | 37 | 41 | 145 | 125 | 130 |

| 6" | 42 | 39 | 50 | 24 | 19 | 26 | 165 | 165 | 160 | 81 | 80 | 86 | 380 | 325 | 345 |

| 3" | 15 | 13 | 16 | 10 | 8 | 9 | 48 | 48 | 48 | 23 | 16 | 20 | 94 | 83 | 86 |

| 8" | 67 | 58 | 81 | 39 | 30 | 45 | 275 | 260 | 300 | 120 | 115 | 140 | 580 | 485 | 530 |

| 5" | 32 | 28 | 35 | 19 | 15 | 20 | 130 | 130 | 140 | 68 | 63 | 68 | 245 | 210 | 225 |

| 12" | 140 | 115 | 185 | 80 | 64 | 110 | 690 | 580 | 690 | 225 | 200 | 295 | 1525 | 1100 | 1300 |

| 10" | 91 | 81 | 124 | 52 | 43 | 70 | 455 | 435 | 510 | 190 | 170 | 230 | 1075 | 930 | 1025 |

| 16" | 250 | 190 | 295 | 140 | 98 | 180 | 1250 | NA | 1300 | 390 | 330 | 495 | NA | NA | NA |

| 14" | 180 | 165 | 250 | 110 | 90 | 140 | 940 | NA | 975 | 280 | 230 | 355 | NA | NA | NA |

| 20" | 400 | 315 | 505 | 180 | 165 | 285 | 2050 | NA | 2225 | 590 | 510 | 810 | NA | NA | NA |

| 18" | 320 | 250 | 395 | 150 | 130 | 220 | 1625 | NA | 1750 | 475 | 400 | 630 | NA | NA | NA |

| 24" | 580 | 475 | 790 | 260 | 220 | 430 | 3325 | NA | 3625 | 830 | 730 | 1250 | NA | NA | NA |

| 22" | 465 | 370 | 640 | 225 | 185 | 355 | NA | NA | NA | 720 | 590 | 1000 | NA | NA | NA |

USA Piping Solution - Trusted CS flange Supplier in USA

When your projects demand Carbon Steel Flanges engineered for lasting performance, connect with USA Piping Solution. Contact us for a detailed Request for Quotation (RFQ), and experience our commitment to rapid turnaround and dependable global support. We are ready to address all your Carbon Steel Flanges and piping component needs.

FAQ on Carbon Steel Flange

What is the HS code of carbon steel flanges?

The majority of carbon steel flanges are shipped as per HS/HTS 7307.91 ( Flanges, of iron or steel). End sub-heading and responsibility may depend on material, facing and country of origin, check with your broker when importing.

Do you possess a price list of carbon steel flanges?

Pricing for carbon steel flanges are based on size, pressure grade, material grade (e.g., ASTM A105, A350 LF2, A694), facing (RF/RTJ/FF), and quantity. Email sales@usapipingsolution.com best price list and inventory, same day quotes, all over the country.

What are the typical flanges of carbon steel?

Weld neck, slip-on, blind, socket weld, threaded, lap joint, orifice and spectacle blinds. When used in high-pressure service with high cyclic rate or on a slipping line, weld neck is to be used and when it is economical to install it, slip-on should be selected.

What are the flange sizes of carbon steel?

Standard range is ½" to 48". ASME B16.5 and ASME B16.47 (Series A/B) have 1/2-24 and 26-48 respectively. Pressure classes include 150, 300, 600, 900, 1500, 2500.

What are the dimensions and specifications of carbon steel flange?

Measures are in accordance with ASME B16.5/B16.47 and MSS SP-44 (OD, thickness, bolt circle, drilling). Ask us to provide you with our carbon steel flange size sheets which are downloadable or add size/class to your RFQ and have us provide you with the matching spec.

What are Carbon Steel Flanges ?

Carbon steel flanges are manufactured using carbon steel, which is a powerful and tough alloy that is mainly a mixture of iron and carbon. Commonly welded types of flanges are used as piping components in the construction.

Related Carbon Steel Products Supplied in USA