IBR Approved Boiler Tubes Manufacturer & Supplier in USA

USA Piping Solution is a company that supplies IBR Approved Boiler Tubes and IBR Pipes and Tubes in the USA. One of the most important independent organizations that determine and control the overall manufacturing regulations of boilers is the Indian Boiler Regulation (IBR), which would guarantee the utmost safety and quality. All IBR Pipes supplied by us are in strict compliance with all the required construction codes including IBR Pipe Material, design, fabrication, and stringent inspection and test requirements. Every manufacturer is obliged to operate in accordance with the most up-to-date IBR code. We are one of the leading IBR Pipes suppliers, and we make sure that all the products are of these strict codes, and the manufacturing process of the product is controlled by an inspecting officer prior to delivery.

Application of IBR Pipes and Tubes offers essential differentiation by comparison to non-IBR items. The major distinction is that IBR Tube Material is obligated and falls under IBR regulation which gives a degree of tested confidence that non-IBR material does not have. One of the products such as IBR Seamless Pipe has reduced chances of accidents due to the fact that it employs certified material and the regulatory control gives the client confidence. Moreover, IBR Tubes and pipes provide extended service life and also less maintenance is required. This implies that a small increase in investment will result in a high savings in the long term. IBR Steam Pipe passes several third-party certified government inspections to ensure safety and performance, which non-IBR pipes never guarantee.

USA Piping Solution is one of the major manufacturers of IBR Pipes and IBR Tubes in the USA which are used in supply to various industries across the world. We employ the most modern technology to make our line of pipes dimensionally correct. Customers are also able to call us to have personal Boiler Tubes as per their specifications, and we ensure fast and reliable doorstep delivery.

Table of Contents

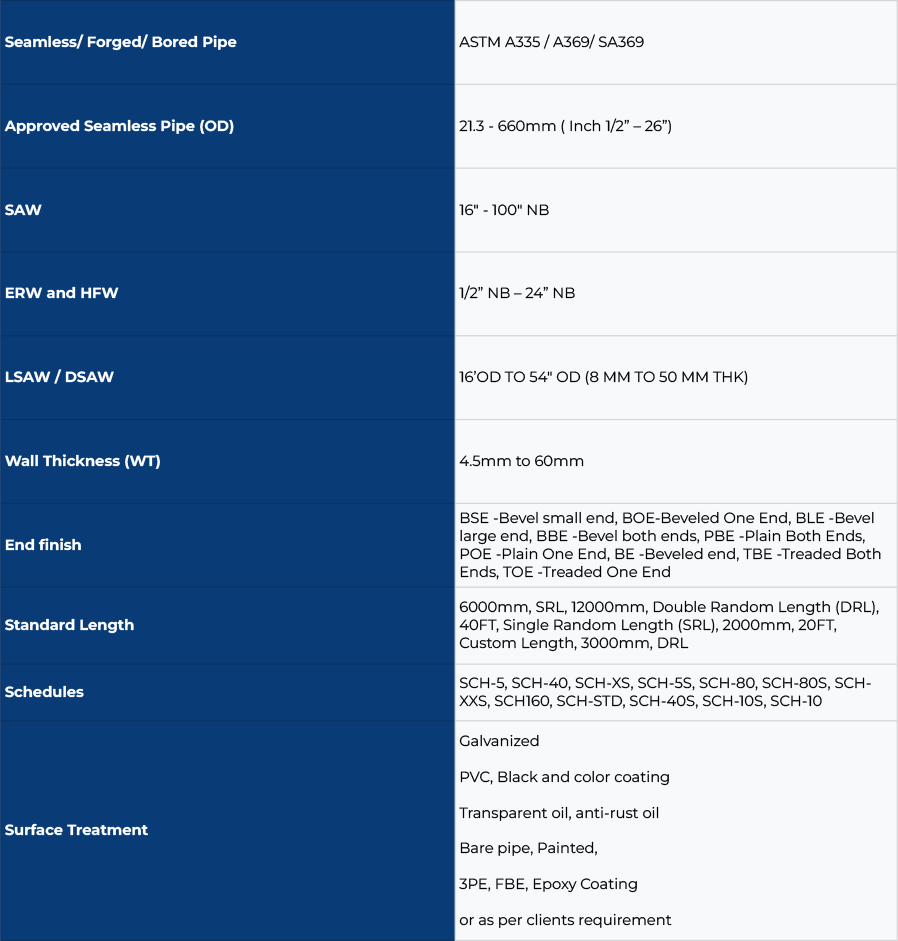

IBR Pipe Material Specification

Request Your IBR Pipes & Tubes Quote Today!

IBR Pipe Types

IBR Seamless Pipe

IBR ERW Pipe

IBR Welded Pipe

IBR Certified Round Pipe For Power Plant

Carbon Steel IBR Thick Wall Seamless Pipe

10inch SCH100 IBR Steel Seamless Pipe

Stainless Steel IBR High Temperature Boiler Pipe

SCH 20 16 inch IBR Seamless Pipe

Cold/ Hot Rolled ASTM A213 IBR Material

A335 Gr IBR Cold Rolled Alloy Steel Seamless Pipe

IBR Approved Boiler Pipe

IBR Approved Cold Drawn Seamless Pipe

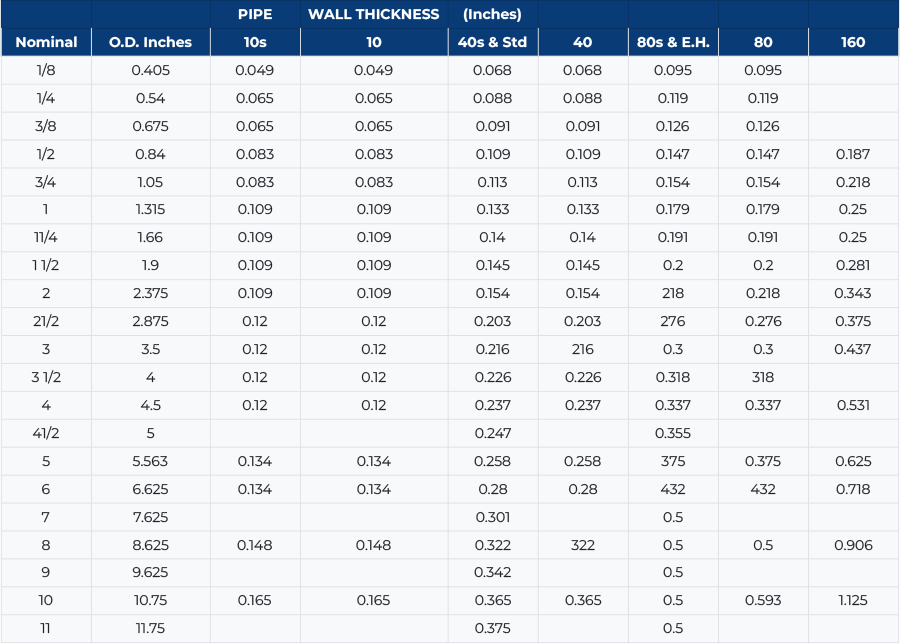

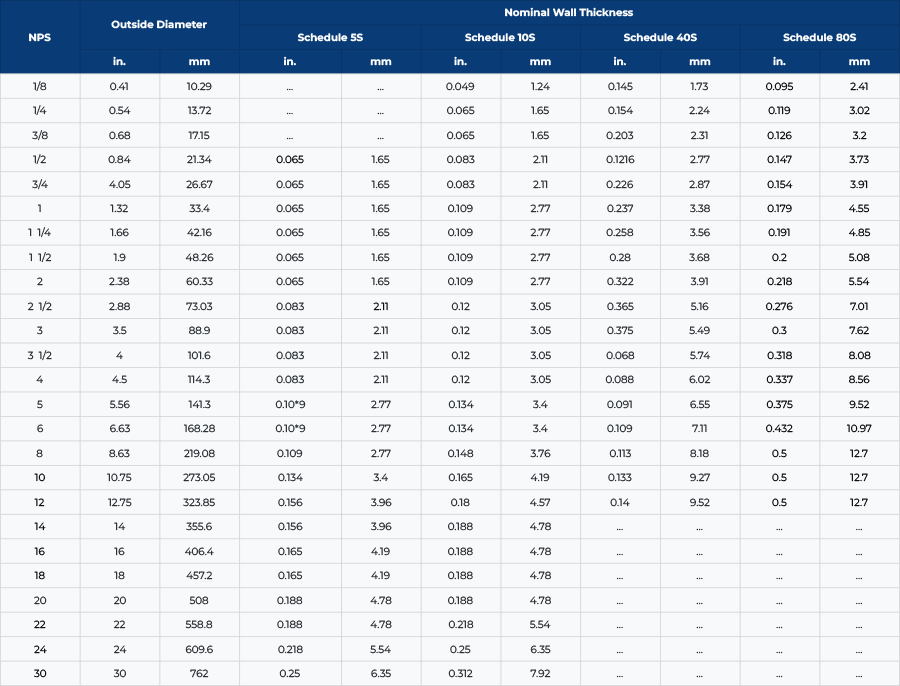

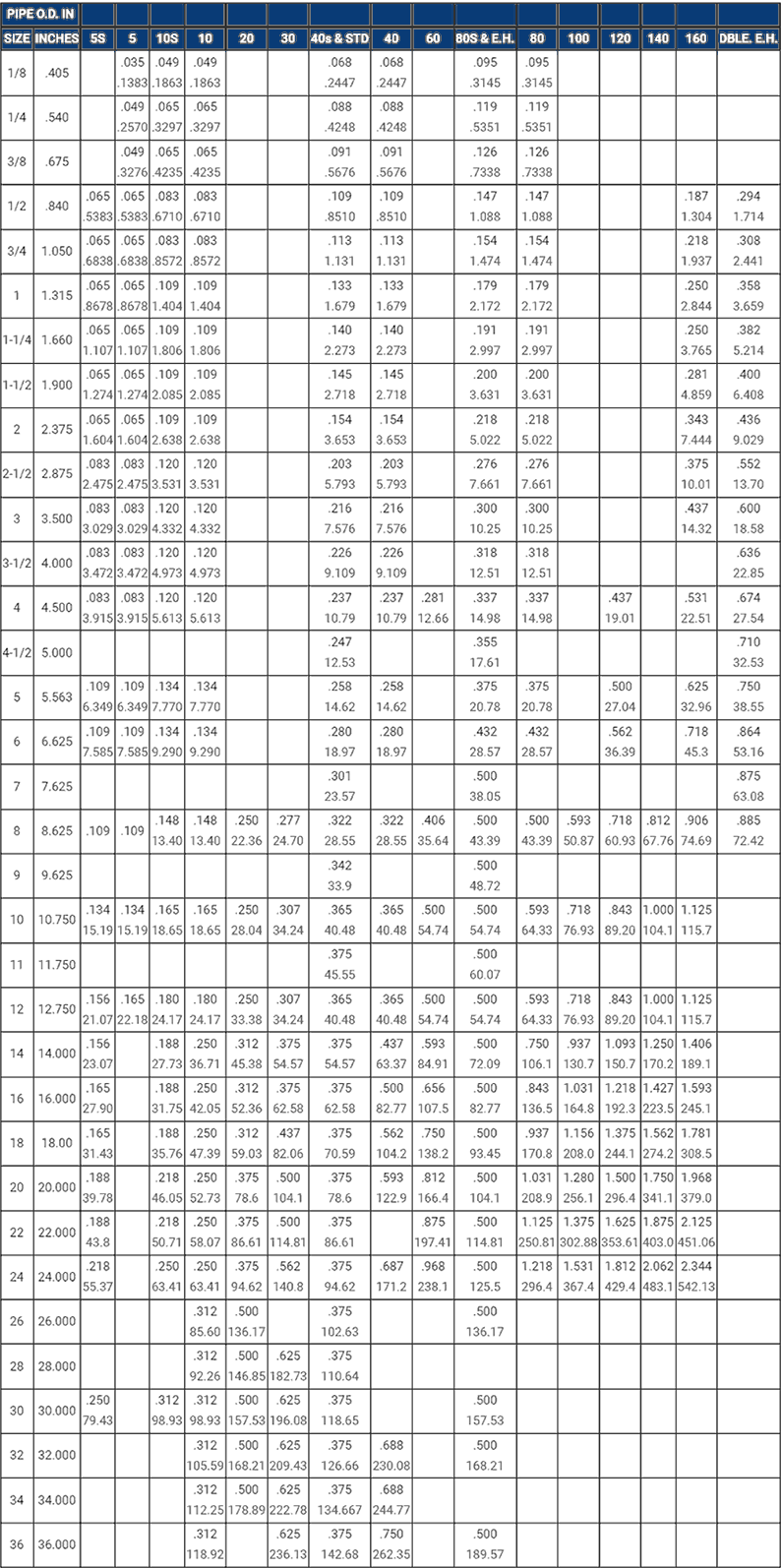

IBR Approved Pipe Thickness Chart

IBR Pipe Schedule Chart

IBR Pipe Weight Chart

IBR Tube Material Grades

We supply IBR Pipes & Tubes in the following material grades:

| Stainless Steel: | TP 304, 304L, 304H, 310, 310S, 316, 316H, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 904L |

|---|---|

| Carbon Steel: | ASTM A53, ASTM A106 Gr. A , B & C API 5L Gr. A / B, X42 ,X52 ,X60, ASTM A 53 Gr. A/B, ASTM A 333 GR.1/6, ASTM A179, ASTM A192 ASTM A179, DIN 17175/2391 BS 3059/ Gr 1 & Gr 2, ASTM A 334 GR.1/8/6 |

| Alloy Steel: | ASTM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 – T5, T9, T11, T12, T22, T91, ASTM A691 |

IBR Steel Pipe Application

The use of IBR (Indian Boiler Regulations) steel pipes and tubes is necessary, and they are high performance components that have widespread application in the power and energy industries and in general industry. They are strong in structure, with the capacity to withstand high pressure and high temperature, thus being applicable in many severe activities.

- Boiler Manufacturing:

These pipes and IBR Boiler Tubes are primary units of construction of boilers applied in power plants, industrial processes and other heating systems. They are long lasting and hence can be used in extreme situations. - Power Generation:

The piping that is IBR-compliant is very important in the case of carrying essential fluids such as steam and hot water in the power generation plants. They are also constructed with high thermal conductivity and are specifically meant to serve in high temperatures. - Heat Exchangers:

IBR Pipes and Tubes are produced in the form of heat exchangers in industrial heat transfer systems. They offer high heat transfer characteristics as well as high corrosion resistance. - Oil and Gas Industry:

The pipes are involved in transportation of crude oil, natural gas and other oil products in a safe manner. They are designed to withstand the high pressures as well as the corrosive conditions, which are characteristic of this industry. - Chemical Industry:

The IBR pipes and tubes can be crucial in the transportation of corrosive chemicals, acids, and other heavy metals because of their ability to resist corrosion and work under extreme conditions.

Related Products

- ASTM A106 Grade B

- ASTM A53 Grade B

- ASTM A179 Tubes

- ASTM A192 Tubes

- ASTM A210 Grade A1 Tubes

- ASTM A335 P1 Pipes

- ASTM A335 P5 Pipes

- ASTM A335 P91 Pipes

- ASTM A335 P11 Pipes

- ASTM A335 P22 Pipes

- ASTM A335 P91 Pipes

- ASTM A213 T11 Tubes

- ASTM A213 T5 Tubes

- ASTM A213 T91 Tubes

- ASTM A213 T11 Tubes

- ASTM A213 T22 Tubes

- ASTM A213 T91 Tubes

- Boiler & Heat Exchanger Tubes

Frequently Asked Questions About IBR Pipes & Tubes

What is an IBR pipe?

IBR pipe refers to the high quality of pipes that are produced and approved to satisfy the high safety standards of the Indian Boiler Regulations (IBR). These pipes are engineered to perform under high pressure and temperature and where the situation requires high pressure and temperature as in boilers, steam systems and heat exchangers.

What qualifies IBR Pipe?

A component generally requires IBR certification unless it falls below certain exemption criteria. These exemptions typically apply to vessels with a capacity of less than 25 liters, or those operating with a design and working gauge pressure of less than 1 Kg per cm square, or where water is heated below 100°C. Any pipe or vessel operating outside of these limited criteria must adhere to the full IBR specifications.

IBR Pipe Pressure Rating

For steam pipe applications that fall under IBR jurisdiction, the minimum specified pressure rating is typically 3.5 kg/cm2

Difference Between IBR and Non IBR Pipe

The gist is regulatory compliance: IBR Pipe is directly exempt to the Indian Boiler Regulations (a law of India), which implies that the manufacturers have to adhere strictly to the IBR regulations in the design, material, manufacture, installation and operation. Conversely, Non-IBR Pipes are pipes or tubes that do not fall under these particular Indian Boiler Regulations normally due to their operating ranges (pressure, temperature or capacity) that are below the minimum level that would necessitate certification.