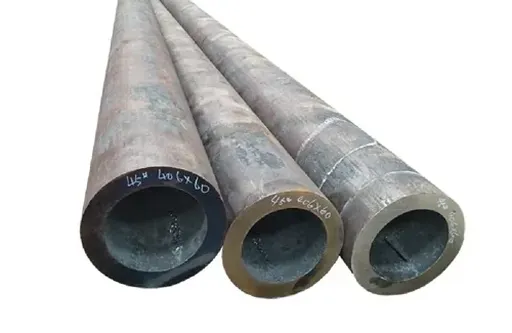

ASTM A179/ASME SA179 seamless carbon steel tubes are designed to be applied in heat exchanger, condensers and boilers where an exceptionally high heat transfer and pressure resistance are needed. Low-carbon steel is used in manufacturing these tubes to ensure high thermal conductivity, uniformity of the wall thickness, and dependability of the tubes in the circumstances of moderate pressure and temperature.

SA179 tubes are easy to construct and hence provide better mechanical strength, surface finish and scaling resistance in comparison with welded counterparts. This has made ASTM A179 carbon steel tubes popular in the power plants, refineries, chemical processing units, and heat recovery units.

Looking to buy Boiler & Heat Exchanger Tubes?

Check price of SA192 Boiler Tubes & SA178 Boiler Tubes

ASTM A179 Heat Exchanger Seamless Tubes Supplier in USA

As a trusted ASTM A179 seamless tubes supplier in the USA, we offer SA179 tubes in a wide range of outside diameters, wall thicknesses, and lengths, suitable for demanding boiler and heat exchanger applications. All tubes are manufactured in compliance with ASTM A179 / ASME SA179 material specifications and supplied with complete test certification.

Our ASTM A179 carbon steel tubes are known for:

- High dimensional accuracy

- Excellent heat transfer efficiency

- Smooth internal surface finish

- Long service life in thermal systems

ASTM A179 / SA 179 Material Specification

| Specification Parameter | Details |

|---|---|

| Standard | ASTM A179 / ASME SA179 |

| Manufacturing Process | Cold Drawn Seamless |

| Product Form | Round |

| End Finish | Plain Ends (PE), Beveled Ends (BE), Threaded Ends (TE) |

| Length | Single Random (SR), Double Random (DR), or Cut Length |

Chemical Composition of ASTM A179 Carbon Steel Tubes

| Element | Percentage (%) |

|---|---|

| Carbon | 0.06 – 0.18 |

| Manganese | 0.27 – 0.63 |

| Phosphorus | ≤ 0.035 |

| Sulfur | ≤ 0.035 |

The low carbon content ensures excellent weldability and thermal efficiency, making SA179 tubes ideal for heat exchange systems.

SA179 Tubes Material Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 325 MPa |

| Yield Strength | ≥ 180 MPa |

| Elongation | ≥ 35% |

These mechanical properties allow ASTM A179 tubes to perform reliably under cyclic heating and cooling conditions.

ASTM A179 Tubes Size Range

| Parameter | Size Range |

|---|---|

| Outside Diameter | 6.35 mm to 76.2 mm |

| Wall Thickness | 1.2 mm to 12 mm |

| Nominal Bore | ¼” to 3” |

Custom sizes are available on request.

ASTM A179 Tube Equivalent Grades

| ASTM / ASME Standard | European / International Equivalent |

|---|---|

| ASTM A179 | ASME SA179 |

| DIN 17175 | St 35 |

| EN 10216-1 | P235GH |

| BS 3059 Part 1 | Grade 320 |

ASTM A179 vs ASTM A106 Grade B Comparison

ASTM A179 tubes are designed for heat transfer efficiency, while ASTM A106 Grade B seamless pipes are intended for high-temperature and high-pressure fluid transport. SA179 tubes have lower carbon content, offering better thermal conductivity, whereas A106 Grade B provides higher strength for pressure piping systems.

Applications of ASTM A179 Carbon Steel Seamless Tubes

- Heat Exchangers

- Surface Condensers

- Steam Boilers

- Power Plants

- Refineries

- Chemical Processing Units

- Fertilizer Plants

- Sugar Mills

Related Products

Request Your ASTM A179 / ASME SA179 Seamless Tubes Quote Today

Get competitive pricing, fast delivery, and certified quality for your boiler and heat exchanger tube requirements.

Request Your SA179 Tubes / A179 Tubes Quote Today!