ASTM A210 Grade A1 tubes are medium to high-pressure boiler and superheater tubes that are made of seamless medium-carbon steel. These tubes are manufactured to ASTM A210 / ASME SA210 and are commonly utilized in steam boilers, superheaters, heat exchangers, condensers and pressure systems where strength, thermal stability and long life are critical.

USA Piping Solution is the supplier of the ASME SA210 Grade A1 seamless boiler tubes of uniform metallurgy, exact dimensions, and fully in line with the quality standards of ASTM, ASME and EN. Our SA210 A1 tubes are also relied on in the power plants, refineries, petrochemical units and industrial boiler systems around the world.

What is ASTM A210 Grade A1?

ASTM A210 is a standard specification of smooth seamless medium-carbon steel tubes that are used in boilers and superheaters. The most common grade used under this specification is grade A1 which provides a combination of strength, ductility and thermal conductivity.

ASME SA210 is the pressure-equipment code equivalent of ASTM A210, and is commonly used in the specifications of boilers and high-temperature piping systems.

ASTM A210 Grade A1 tubes are of ferritic type and can be used in ongoing operations at high temperatures, thus being the best to use in the steam-based systems.

Looking to buy Boiler & Heat Exchanger Tubes?

Check price of SA192 Tubes Boiler Tubes & SA178 Boiler Tubes

Why ASTM A210 Grade A1 is Used in Boilers & Superheaters

ASTM A210 Grade A1 is widely preferred in boiler and superheater applications because its higher carbon content compared to ASTM A179 and ASTM A192 provides improved strength and pressure-handling capability, while its excellent resistance to thermal fatigue allows it to perform reliably under repeated heating and cooling cycles; the grade maintains stable mechanical properties at elevated operating temperatures, and its seamless construction eliminates weld-related weaknesses, resulting in a long service life in demanding steam environments making SA210 A1 tubes ideal for use in boiler drums, superheaters, economizers, and high-temperature steam lines.

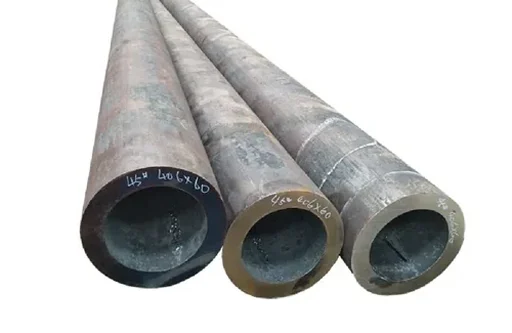

Manufacturing Process of SA210 Grade A1 Tubes

Hot Finished Seamless Tubes

Hot-finished SA210 A1 tubes are produced directly from solid billets. They offer:

- Uniform microstructure

- Excellent high-temperature strength

- Suitability for thicker wall applications

Cold Finished (Cold Drawn) Seamless Tubes

Cold-finished tubes are drawn to tighter tolerances and provide:

- Superior surface finish

- Accurate wall thickness

- Improved heat transfer efficiency

Cold-finished tubes undergo sub-critical annealing, full annealing, or normalizing after final drawing.

ASTM A210 Grade A1 Boiler Tube Specification

| Parameter | Details |

|---|---|

| Standard | ASTM A210 / A210M, ASME SA210 |

| Grade | A1 |

| Manufacturing | Hot finished / Cold finished |

| Size Range | 1/2" NB to 16" NB |

| Outer Diameter | 12.7 mm to 406.4 mm |

| Wall Thickness | 1.5 mm to 50 mm |

| Length | SRL / DRL / Custom, up to 25 m |

| Shape | Round |

| Heat Treatment | As per ASTM A210 |

| Testing Standard | ASTM A450 / A450M |

| Certification | EN 10204 3.1 / 3.2 |

SA210 Gr A1 Material Composition

| Grade | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| A1 | 0.27 | Max 0.93 | 0.10 | 0.035 | 0.035 |

The controlled carbon and manganese content improves high-temperature strength and toughness, while low sulphur and phosphorus enhance weldability and resistance to cracking.

Mechanical Properties of SA210 A1 Boiler Tube

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 |

| Yield Strength | ≥ 255 |

| Elongation | ≥ 30 |

| Hardness | ≤ 79 |

These mechanical values ensure the tube can withstand high internal pressure, thermal stress, and continuous steam exposure without deformation.

ASTM A210 Grade A1 vs A192 vs A179

| Grade | Temperature Resistance | Pressure Capability | Typical Application |

|---|---|---|---|

| ASTM A179 | Low–Medium | Low | Heat exchangers |

| ASTM A192 | High | High | High-pressure boilers |

| ASTM A210 A1 | Medium–High | Medium–High | Boilers & superheaters |

A210 A1 serves as a bridge grade, offering better strength than A179 and wider usability than A192.

ASME SA 210 Grade A1 Boiler Tube Tolerance

| Outside Diameter in MM | Cut Length in MM | |

|---|---|---|

| Over (+) | Under (-) | |

| All Sizes | 3⁄16 [5] | 0 [0] |

| Under 2 (50.8) | 1⁄8 [3] | 0 [0] |

| 2 (50.8) and over | 3⁄16 [5] | 0 [0] |

| Under 2 (50.8) | 1⁄8 [3] | 0 [0] |

| 2 (50.8) and over | 3⁄16 [5] | 0 [0] |

SA 210 Grade A1 Heat Exchanger Pressure Rating

| Outer Diameter of Tube in mm | Hydrostatic Test Pressure |

|---|---|

| Under 1 [25.4] | 1000 [7] |

| 1 to 11⁄2 [25.4 to 38.1], excl | 1500 [10] |

| 11⁄2 to 2 [38.1 to 50.8], excl | 2000 [14] |

| 2 to 3 [50.8 to 76.2], excl | 2500 [17] |

| Tube OD (mm) | Test Pressure |

|---|---|

| ≤ 25.4 | 7 MPa |

| 25.4 – 38.1 | 10 MPa |

| 38.1 – 50.8 | 14 MPa |

| 50.8 – 76.2 | 17 MPa |

Each tube is hydrostatically tested unless replaced by approved non-destructive testing

Types of ASTM A210 Grade A1 Tubes

Surface finish options include black, pickled, oiled, galvanized, painted, or annealed.

Applications of ASME SA 210 Grade A1 Boiler Tube

ASTM A210 Grade A1 tubes are widely used in:

- Steam boilers

- Superheater and reheater units

- Heat exchangers and condensers

- Power generation plants

- Oil & gas refineries

- Petrochemical processing units

- Fertilizer and chemical plants

- Paper and pulp industries

Their ability to handle high pressure and elevated temperature makes them ideal for critical thermal systems.

Testing & Quality Standards

ASTM A210 Grade A1 tubes undergo strict quality checks including hydrostatic or non-destructive testing, flattening and flaring tests, chemical analysis, mechanical testing, and detailed dimensional inspection to ensure full compliance with ASTM A210, ASME SA210, and ASTM A450/A450M requirements

Related Products

.webp)

.webp)