DIN 2391 ST37 welded steel tubes are engineered for applications that demand controlled tolerances, uniform wall thickness, and consistent performance. These high precision carbon steel are tubes normally utilized in car parts, built structures, and machine assemblies where size control is paramount. ST37 grade (material number 1.0037) is one that provides consistent mechanical performance that allows precise machining, bending, and welding processes.

Having a low-carbon content of about 0.20, DIN 2391 ST37 provides a reasonable trade off between strength and workability. It is similar to the EN S235JR and Q235 steel grade, thus is an acceptable material to be applied in international projects. Although the ST37 welded tubes are not designed to perform the functions of high-tensile loads as ASTM A36, the tubes are still cost-effective in structural frameworks, support structures, and fabrication of precision. These tubes are available in black, painted or galvanized finishes depending on the exposure of the environment where they are to be used thus the decision on corrosion protection rests on the service requirements of the user.

DIN 2391 ST37 Carbon Steel Welded Tube Manufacturer & Supplier in USA

USA Piping Solution supplies DIN 2391 ST37 carbon steel welded tubes designed to meet the operational requirements of modern industrial and engineering systems. Our manufacturing process focuses on dimensional consistency, surface quality, and material integrity, ensuring dependable performance across mechanical, structural, and fluid-transfer applications. In addition to DIN 2391, we offer compatible solutions under DIN 1626 and DIN 2448 standards to support diverse project specifications.

The characteristics that make DIN 2391 ST37 welded tubes useful include ease of fabrication and structural stability. The material facilitates cold forming and welding without ruining mechanical characteristics, thus it can be used in components that need a high degree of repeatable accuracy and long durability. The tubes have good workability in medium pressure and structural conditions where consistency and cost containment are also significant.

Our pipes of ST37 are available in a large variety of diameters, wall thicknesses, and finishes to meet the requirements of a project. There are optional surface treatments, clear identification marking, and protective packs that are applied to products to guarantee safe handling and installation. The quality of the supplied lot is verified in order to ensure that the supply lot meets the dimensional and material quality in order to ensure that the clients are consistent across their implementation.

Looking to buy Carbon Steel Pipes & Tubes?

Check price of Carbon Seamless Pipes & Tubes & Carbon Welded Pipes & Tubes

Table of Contents

- DIN 2391 ST37 Steel Tube Specifications

- DIN 2391 ST37 Pipe Tolerance

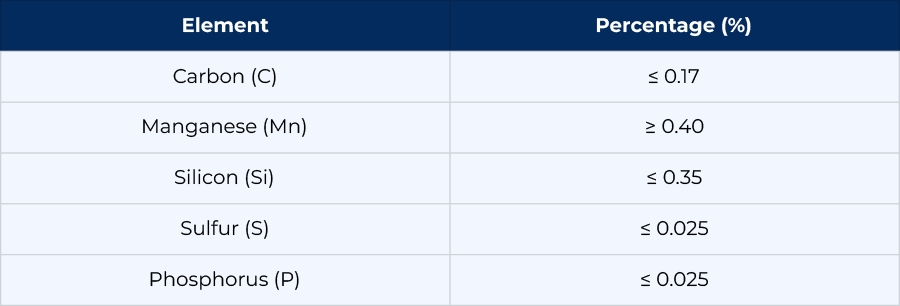

- Carbon Steel DIN 2391 ST37 Tubes Chemical Composition

- ST37 DIN 2391 Carbon Steel Welded Tubes Mechanical Properties

- ST37 DIN 2391 Carbon Steel Tubes Equivalent Material

- Types of DIN 2391 ST37 Carbon Steel Tubes

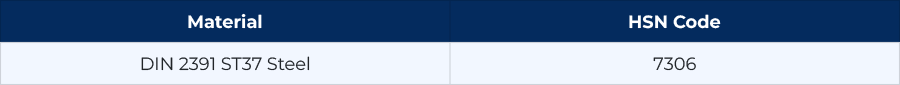

- DIN 2391 ST37.4 Steel Tubes & Pipes HSN Code

- DIN 2391 ST37 Tube Heat Treatment

- Application of ST37 DIN 2391 Steel

- Testing Methods for DIN 2391 ST37 NBK Tubes

- Related Products

- Frequently Asked Questions About ST37 Welded Tubes

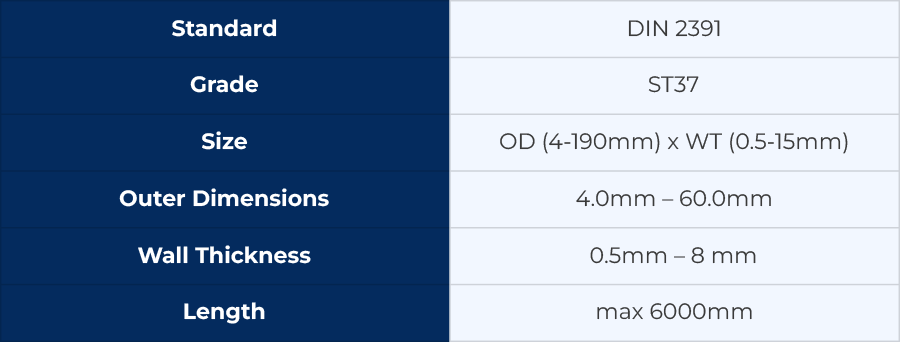

DIN 2391 ST37 Steel Tube Specifications

DIN 2391 ST37 Pipe Tolerance

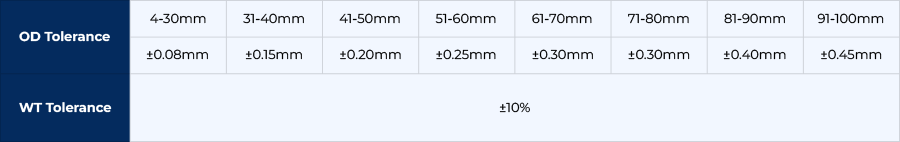

Carbon Steel DIN 2391 ST37 Tubes Chemical Composition

|

Steel grade |

Type of Deoxidation |

Chemical composition in % by wt. Ladle analysis |

Additional Nitrogen combining elements(e.g.at least 0.02% A l total) |

Chemical Composition in % by wt. Sample Analysis |

Steel Grade |

||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

code # |

Material Number |

C |

P |

S |

N |

C |

P |

S |

N |

||||||||||||||

|

for Product thickness in mm |

|

|

|

for product thicknesses in mm |

|

|

|

||||||||||||||||

|

New |

New |

||||||||||||||||||||||

|

≤ 16 |

>16 ≤30

|

>30 ≤40 |

>40 ≤63

|

>63 ≤100

|

>100 |

||||||||||||||||||

|

≤ 16 |

>16 ≤30 |

>30 ≤40 |

>40 < 1 |

>63 ≤100

|

>100 |

||||||||||||||||||

|

|

|

|

|

Max. |

Max. |

|

Max |

Max |

|

||||||||||||||

|

St. 37-2 |

1.0037 |

- |

optional |

0.17 |

0.20 |

0.20 |

0.20 |

0.20 |

by agreement |

0.050 |

0.050 |

0.009 |

- |

0.21 |

0.25 |

0.25 |

0.25 |

0.25 |

|

0.065 |

0.065 |

0.010 |

St.37-2 |

|

Rst. 37-2 |

1.0038 |

1.0114 |

R |

0.17 |

0.17 |

0.17 |

0.20 |

0.20 |

0.050 |

0.050 |

0.009 |

-- |

0.19 |

0.19 |

0.19 |

0.22 |

0.23 |

|

0.060 |

0.060 |

0.010 |

RSt.37-2 |

|

|

St. 37-3 |

1.0116 |

1.0116 |

RR |

0.17 |

0.17 |

0.17 |

0.17 |

0.17 |

0.040 |

0.040 |

--- |

yes |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

|

0.050 |

0.050 |

|

St.37-3 |

|

|

St.60-2 |

1.0060 |

1.0542 |

R |

-- |

-- |

-- |

-- |

-- |

-- |

0.050 |

0.050 |

0.009 |

-- |

-- |

-- |

-- |

-- |

-- |

|

0.060 |

0.060 |

0.010 |

|

|

St.44-3 |

1.0144 |

-- |

RR |

0.20 |

0.20 |

0.20 |

0.20 |

0.20 |

0.040 |

0.040 |

--- |

yes |

0.23 |

0.23 |

0.23 |

0.23 |

0.23 |

|

0.050 |

0.050 |

|

St.44-3 |

|

|

St.44-2 |

1.0044 |

-- |

R |

0.21 |

0.21 |

0.21 |

0.22 |

0.22 |

0.050 |

0.050 |

0.009 |

-- |

0.24 |

0.24 |

0.24 |

0.25 |

0.25 |

|

0.060 |

0.060 |

0.010 |

St.44-2 |

|

|

St.52-3 |

1.0570 |

1.0841 |

RR |

0.20 |

0.20 |

0.22 |

0.22 |

0.22 |

0.040 |

0.040 |

-- |

yes |

0.22 |

0.22 |

0.24 |

0.24 |

0.24 |

|

0.050 |

0.050 |

|

St.52-3 |

|

|

St.50-2 |

1.0050 |

1.0532 |

R |

-- |

-- |

-- |

-- |

-- |

-- |

0.050 |

0.050 |

0.009 |

-- |

-- |

-- |

-- |

-- |

-- |

|

0.060 |

0.050 |

0.010 |

St.50-2 |

|

Ust. 37-2 |

1.0036 |

1.0112 |

U |

0.17 |

0.20 |

0.20 |

0.20 |

0.20 |

0.050 |

0.050 |

0.007 |

-- |

0.21 |

0.25 |

0.25 |

0.25 |

0.25 |

|

0.065 |

0.065 |

0.009 |

USt.37-2 |

|

|

St.70-2 |

1.0070 |

1.0632 |

R |

-- |

-- |

-- |

-- |

-- |

-- |

0.050 |

0.050 |

0.009 |

-- |

-- |

-- |

-- |

-- |

-- |

|

0.060 |

0.060 |

0.010 |

St.70-2 |

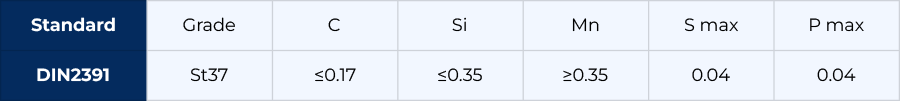

ST37 DIN 2391 Carbon Steel Welded Tubes Mechanical Properties

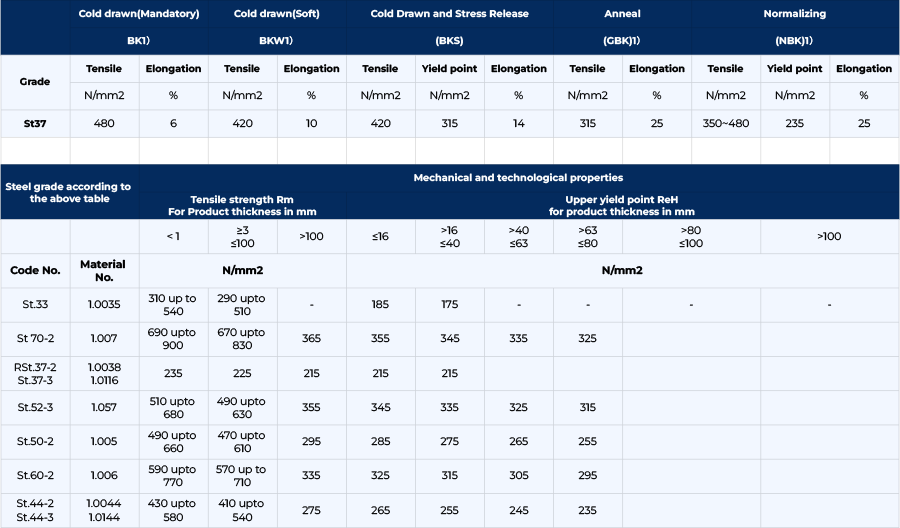

ST37 DIN 2391 Carbon Steel Tubes Equivalent Material

Types of DIN 2391 ST37 Carbon Steel Tubes

Ensuring your materials meet the required standards is fundamental. USA Piping Solution provides St37 Welded Tubes backed by robust quality management and clear documentation:

- DIN 17100 St 37 Welded Tube

- ST37 DIN 2391 Carbon Steel Seamless Pipes

- DIN 2391 ST37 Hot Rolled Carbon Steel Seamless Pipe

- DIN 2391 ST37 Heavy Thick Wall Steel Pipe

- DIN 2391 ST37 alloy steel pipe galvanized steel pipe

- DIN 2391 ST37 Precision Seamless Steel Pipe

- DIN 1.0037 Annealed Tube

- ST37 DIN Seamless circular tubes

- ST37 S235 Cold Finished xTube

- ST37 Mechanical Tubing

St35 Steel HSN Code

DIN 2391 ST37 Tube Heat Treatment

DIN 2391 ST37 steel tubes are subjected to controlled heating in order to enhance mechanical performance, dimensional stability and service life. Quenching and tempering are accomplished by heating tubes to 850 o C-900 o C quenching then tempering to 550 o C-700 o C to make them stronger yet tough. Normalizing, conducted at 850 C -950 C, cleanses the grain structure and brings about homogenization of the mechanical characteristics. Stress relieving at 500 C -650 C lowers residual stresses caused during cold working or welding to enhance dimensional accuracy. Annealing, which is normally done at 550 C to 700 C, improves ductility and formability, thus the tubes can be used in precision machining, forming and welded products.

Application of ST37 DIN 2391 Steel

- Pneumatic Systems

- Fluid Conveying Systems

- Automotive Industry

- Mechanical Engineering

- Construction and Building

- Structural Applications

Testing Methods for DIN 2391 ST37 NBK Tubes

For DIN 2391 ST37 NBK tubes, the following non-destructive testing (NDT) methods are commonly used to verify internal soundness, surface quality, and dimensional reliability without damaging the tubes:

- Ultrasonic Testing (UT): Used to detect internal defects such as cracks, voids, or laminations along the tube wall and length, ensuring structural integrity.

- Dye Penetrant Testing (DPT): Applied to identify surface-level cracks, pinholes, or porosity, especially after cold drawing or finishing operations.

- Radiographic (X-ray) Testing (RT): Employed to examine internal weld quality and material consistency where high inspection accuracy is required.

- Eddy Current Testing (ECT): Suitable for detecting surface and near-surface flaws, particularly in precision and hydraulic tube applications.

- Magnetic Particle Testing (MPT): Used for locating surface and slightly subsurface defects in ferromagnetic ST37 steel, mainly around welded or stressed areas.

These NDT methods help ensure that DIN 2391 ST37 NBK tubes meet dimensional accuracy, safety, and performance requirements for mechanical, structural, and hydraulic applications.

Related Products

Request Your St37 Welded Tubes Quote Today!

Frequently Asked Questions About ST37 Welded Tubes

Q1: What is ST37 material?

St37 (Werkstoff 1.0037) is a German DIN standard low-carbon structural steel, often referred to as mild steel. It is highly valued in construction and fabrication for its excellent weldability and formability. The most common variant, St37-2, is equivalent to the European S235JR grade.

Q2: Is St37 safe?

In an industrial context, St37 is safe and reliable for structural and low-pressure fluid applications. Please note: St37 steel is an industrial alloy and should not be confused with "S.T. 37," which is a brand name for a hexylresorcinol-based medical antiseptic solution.

Q3: What is the temperature range of St37?

St37 is typically used in ambient temperature applications. While it can withstand heat in structural settings, it is generally recommended for service temperatures up to 400°C. Beyond this range, the material may experience a significant drop in mechanical strength and oxidation.

Q4: What is the hardness of St 37?

The standard hardness of St37 steel in its normalized or hot-rolled condition typically ranges between 120 and 140 HB (Brinell Hardness). While specialized heat treatments or cold-working can increase this value, it remains a relatively soft and ductile steel compared to high-carbon alloys.