ASTM A106 Grade B seamless pipe is one of the most frequently utilised types of pipes in high pressure and high-temperature service. This grade of pipe is manufactured as per the ASTM A106/ASME SA106 standards and it is used in the industries that need high endurance, fast wear resistance, and thermal resistance.

As a trusted supplier of ASTM A106 Grade B piping, USA Piping Solution can offer smooth carbon steel pipes that meet stringent mechanical, chemical, and measurements demands that can be used in harsh working environments in most industries.

ASTM A106 Grade B Pipe Specification

ASTM A106 is a standard specification on seamless carbon steel pipes that are used in a high temperature application. The specification contains 3 grades which are Grade A, Grade B and Grade C where Grade B is the most popular as it is the best balance of strength, ductile and cost effectiveness.

ASTM A106 Grade B pipes are extensively used in oil & gas pipelines, refineries, thermal power plants, boilers, petrochemical units, and pressure piping systems. These pipes are usually similar to ASTM A53 Grade B and API 5L Grade B in their chemical composition and mechanical characteristics, and are therefore used in both process and structural us

Request for a Quote!

Table of Contents

- ASTM A106 Standard Specification

- Chemical Composition of ASTM A106 Grade B Pipe

- A106 Carbon Steel Pipes Mechanical Properties

- ASME SA 106 Gr B Pipe Equivalent Grades

- What is the Difference Between API 5L Grade B and ASTM A106 Grade B Pipe?

- Standards Referenced for ASTM A106 Pipes

- ASTM A106 Grade Types

Diving into ASTM A106 Grade B Pipe Specifications

| Parameter | Details |

|---|---|

| Standards | ASTM, ASME, API, ANSI B36.10 |

| Manufacturing Process | Cold Rolled / Cold Drawn |

| ANSI Standard | B1.20 |

| Grades | ASTM A106 Grade A, Grade B, Grade C |

| Pipe Type | ERW / Seamless / Fabricated / Welded |

| Size Range | 1/2” NB to 36” NB |

| Length | Minimum 3 meters, Maximum 18 meters |

| Wall Thickness | 3 mm to 12 mm |

| Specialization | Large Diameter ASTM A106 Grade B Pipe |

| Schedules | SCH 20, 30, 40, STD, XH, 80, 100, 120, 140, 160, XXH & heavier |

| ASME Standard | B36.10M |

| Dimensional Tolerance |

Cold Drawn: ±0.1 mm Cold Rolled: ±0.05 mm |

| Pipe Ends | Plain End, Beveled End, Threaded End |

Chemical Composition of ASTM A106 Grade B Pipe

The chemical composition of ASTM A106 Grade B seamless pipe is carefully controlled to deliver excellent weldability, high-temperature strength, and resistance to thermal stress in pressure piping systems.

| Element | Composition (%) |

|---|---|

| Carbon (C) | Max 0.30 |

| Manganese (Mn) | 0.29 – 1.06 |

| Sulfur (S) | Max 0.035 |

| Phosphorus (P) | Max 0.035 |

| Silicon (Si) | Min 0.10 |

| Chromium (Cr) | Max 0.40 |

| Copper (Cu) | Max 0.40 |

| Molybdenum (Mo) | Max 0.15 |

| Nickel (Ni) | Max 0.40 |

| Vanadium (V) | Max 0.08 |

A106 Carbon Steel Pipes Mechanical Properties

ASTM A106 Grade B seamless carbon steel pipes offer reliable mechanical performance for high-temperature and high-pressure service applications.

| Property | Grade B |

|---|---|

| Tensile Strength (Minimum) | 60,000 psi (415 MPa) |

| Yield Strength (Minimum) | 35,000 psi (240 MPa) |

ASME SA 106 Gr B Pipe Equivalent Grades

ASTM A106 Grade B seamless pipes are equivalent to international pressure piping standards used in high-temperature service conditions.

| Execution | Standard | Material Grade |

|---|---|---|

| Seamless Pipe | ASTM A106 | Grade B |

| Seamless Pipe | EN 10216-2 | P265GH |

What is the difference between API 5L Grade B and ASTM A106 Grade B Pipe?

API 5L Grade B pipe is mainly used for oil, gas, and fluid transportation pipelines, where moderate temperatures are involved. It is designed for long-distance pipeline service and good weldability. ASTM A106 Grade B seamless pipe is intended for high-temperature and high-pressure applications such as boilers, power plants, refineries, and process piping.

In short, API 5L Grade B is for pipelines, while ASTM A106 Grade B is for high-temperature industrial piping.

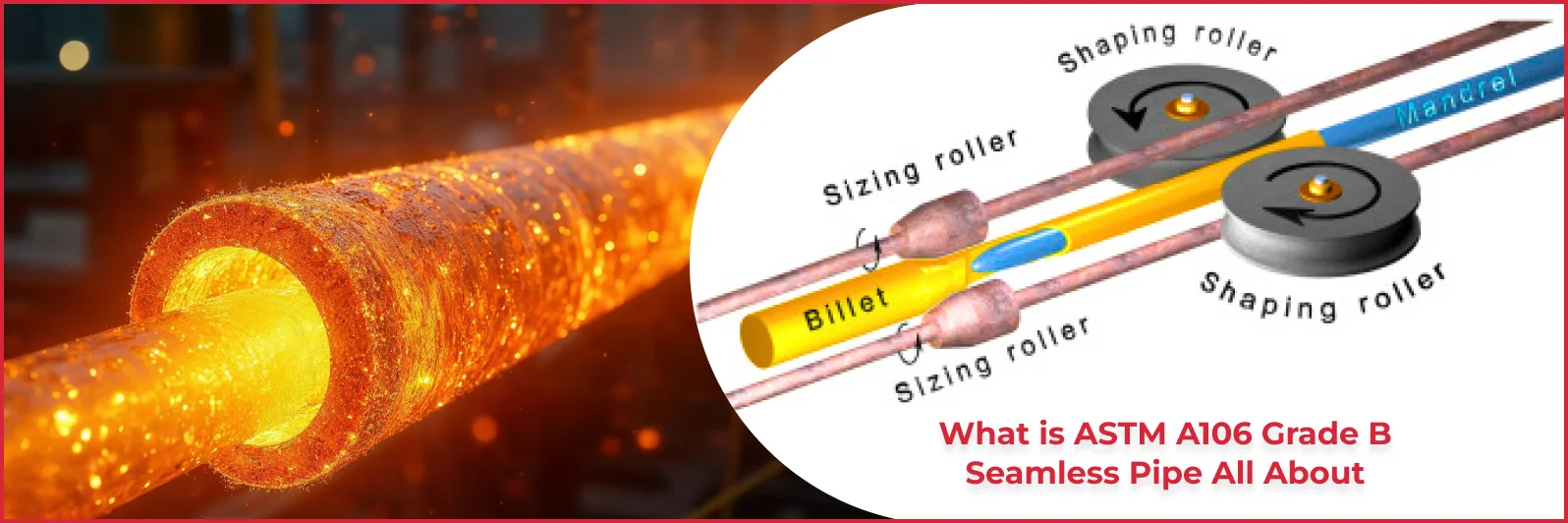

Raw Material & Manufacturing Process of ASTM A106 Grade B Pipe

ASTM A106 Grade B seamless pipes are produced from fully killed carbon steel, making them suitable for hot forming operations such as bending, flanging, and welding. Manufacturing is carried out using hot-finished or cold-drawn processes, ensuring uniform wall thickness, dimensional accuracy, and consistent mechanical properties.

For applications requiring enhanced performance, supplementary testing and inspection requirements can be specified at the time of order.

Standards Referenced for ASTM A106 Pipes

ASTM A106 pipes are manufactured and tested in accordance with multiple international standards, including:

- ASTM A530 / A530M – General requirements

- ASTM E213 – Ultrasonic testing

- ASTM E309 – Eddy current testing

- ASTM E381 – Macroetch testing

- ASTM E570 – Flux leakage testing

- ASME B36.10M – Pipe dimensions

- MIL-STD-129 – Marking for shipment

- MIL-STD-163 – Storage and shipment

- SSPC-SP 6 – Surface preparation

ASTM A106 Grade Types

The ASTM A106 specification includes three grades:

- Grade A: Lower strength for general-purpose applications

- Grade B: Most widely used grade with balanced mechanical properties

- Grade C: Higher strength for demanding service conditions

Among these, Grade B seamless pipes are preferred for high-temperature pipelines, pressure systems, and energy-sector applications.

Testing Methods for ASTM A106 Grade B Pipes

All ASTM A106 Grade B seamless pipes undergo stringent quality testing to ensure compliance with international standards. Common test methods include:

- Hydrostatic testing

- Flattening test

- Ultrasonic testing

- Eddy current testing

- Flux leakage testing

Testing requirements are finalized based on project specifications, service conditions, and end-use applications.

Applications of ASTM A106 Grade B Seamless Pipe

ASTM A106 Grade B seamless carbon steel pipes are commonly used in:

- Oil & gas transmission pipelines

- Boiler and heat exchanger systems

- Power generation plants

- Refineries and petrochemical facilities

- High-temperature process piping

- Structural and pressure vessel applications

Related Products

API 5L Carbon Steel Pipes