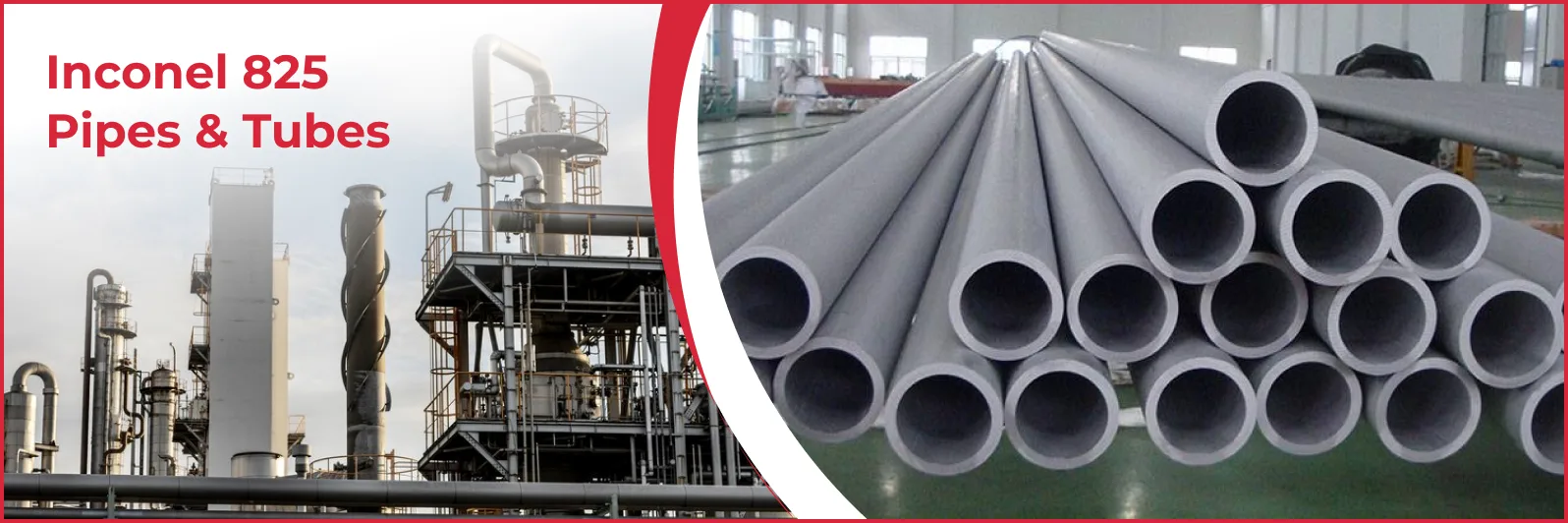

ASTM B423 / ASME SB423 Incoloy 825 Pipes & Tubes Manufacturer in USA

Incoloy 825 pipes & tubes are nickel-iron-chromium based alloys that are alloyed with molybdenum and copper to provide excellent resistance in acidic, chloride based and corrosive industrial environments. It is a metallurgically based sulfuric acid, phosphoric acid, and offshore service material that is commonly specified as a sulfuric acid, phosphoric acid, and offshore service material when the corrosion resistance over an extended period is paramount.

USA Piping Solution is a reputable Incoloy 825 pipe manufacturer and supplier in USA, which sells alloy 825 pipe and alloy 825 tubing in seamless, ERW, welded and fabricated. These products are produced per ASTM and ASME recommendations and they are shipped along with complete traceability of the material used as well as mill test certification in addition to other high nickel alloy piping products like Inconel pipes and tubes.

Incoloy 825 piping systems are also suitable in continuous operation in chemical processing plants, offshore oil and gas platforms, pollution control units and in heat exchanger systems unlike traditional stainless steels, which can only withstand the whole range of temperatures.

Why Alloy 825 Pipes Are Used in Acidic & Chloride Environments

Incoloy 825 pipe is uniquely designed with the ability to resist corrosion processes that tend to attack stainless steel as well as lower nickel alloys. The resistance to pitting and crevice corrosion is optimized with the controlled addition of molybdenum, and copper is an important improvement in sulfuric and phosphoric acid service.

This renders alloy 825 pipes and alloy 825 Tubing as a favorite in acid handling systems, offshore structure and chemical reactors. Incoloy 825 tubes also have a great resistance to chloride- induced stress corrosion cracking, thus long run reliability in marine and offshore setups.

Looking to buy Exotic Alloy Pipes & Tubes?

Check price of Inconel 600 Pipes & Tubes & Incoloy 800 Pipes & Tubes

Specification of Incoloy 825 Pipes & Tubes

Incoloy 825 pipes and tubes are manufactured to meet stringent international standards, ensuring excellent corrosion resistance, dimensional accuracy, and extended service life in aggressive industrial environments.

| Category | Specification |

|---|---|

| Pipe & Tube Standards |

ASTM B407 / ASME SB407 – Seamless Pipes ASTM B163 / ASME SB163 – Heat Exchanger & Condenser Tubes ASTM B358 / ASME SB358 – Welded Pipes & Tubes ASTM B515 / ASME SB515 – Welded Heat Exchanger Tubes |

| Size Range | Nominal Bore (NB): 15 NB to 150 NB |

| Manufacturing Types |

Seamless ERW Welded Fabricated LSAW Pipes |

| Forms Available |

Round Square Rectangular Hydraulic Tubes |

| Pipe Length |

Single Random Double Random Custom Cut Lengths |

| Pipe Ends |

Plain End (PE) Beveled End (BE) Threaded End (TE) |

Chemical Composition of Incoloy 825 Alloy Pipes

The chemical composition of Incoloy Alloy 825 pipes is precisely controlled to provide superior resistance to acids, pitting, and stress corrosion cracking.

| Element | Min (%) | Max (%) |

|---|---|---|

| Carbon (C) | – | 0.05 |

| Manganese (Mn) | – | 1.0 |

| Silicon (Si) | – | 0.5 |

| Iron (Fe) | 22.0 | – |

| Sulfur (S) | – | 0.015 |

| Chromium (Cr) | 19.5 | 23.5 |

| Copper (Cu) | 1.5 | 3.0 |

| Titanium (Ti) | 0.6 | 1.2 |

The presence of molybdenum, copper, and titanium enhances resistance to localized corrosion and stabilizes the alloy against sensitization during welding and high-temperature service.

Mechanical Properties of Incoloy Alloy 825 Pipes

Incoloy 825 pipes offer an excellent balance of strength, ductility, and toughness, making them suitable for both pressure and non-pressure applications.

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Rockwell B (HRB) max | Brinell (HB) max |

|---|---|---|---|---|---|

| 825 | 550 MPa (80,000 psi) |

220 MPa (32,000 psi) |

30 | – | – |

These properties remain stable across a wide operating temperature range, making Incoloy 825 tubing suitable for pressure and non-pressure applications.

Equivalent Grades for Incoloy 825 Pipes

Incoloy 825 is recognized globally under various international standards, allowing easy material substitution and global project compliance.

| Standard | Grade |

|---|---|

| UNS | N08825 |

| EN | 2.4858 |

| BS | NA 16 |

| AFNOR | NFE30C20DUM |

| GOST | ЭП703 |

| JIS | NCF 825 |

Alloy 825 Pipe Pressure Rating

Incoloy 825 pipe is designed for demanding pressure applications. Pressure ratings vary based on OD and wall thickness, ensuring safe use in high-pressure chemical and heat exchanger systems.

| Standard | Grade |

|---|---|

| UNS | N08825 |

| EN | 2.4858 |

| BS | NA 16 |

| AFNOR | NFE30C20DUM |

| GOST | ЭП703 |

| JIS | NCF 825 |

Inconel 825 Pipe Dimensions Chart

| OD (in) | Wall 0.035" | Wall 0.049" | Wall 0.065" | Wall 0.083" |

|---|---|---|---|---|

| 1/4" | 4,800 | 7,000 | 9,500 | – |

| 3/8" | 3,100 | 4,400 | 6,100 | – |

| 1/2" | 2,300 | 3,200 | 4,400 | – |

| 3/4" | – | 2,200 | 3,000 | 4,000 |

| 1" | – | – | 2,200 | 2,900 |

Incoloy 825 Pipe Schedule and Wall Thickness Chart

| NPS (in) | OD (in) | Sch 10S | Sch 40S | Sch 80S |

|---|---|---|---|---|

| 1/2" | 0.840 | 0.083 | 0.109 | 0.147 |

| 3/4" | 1.050 | 0.083 | 0.113 | 0.154 |

| 1" | 1.315 | 0.109 | 0.133 | 0.179 |

| 1 1/2" | 1.900 | 0.109 | 0.145 | 0.200 |

| 2" | 2.375 | 0.109 | 0.154 | 0.218 |

| 3" | 3.500 | 0.120 | 0.216 | 0.300 |

| 4" | 4.500 | 0.120 | 0.237 | 0.337 |

| 6" | 6.625 | 0.134 | 0.280 | 0.432 |

| 8" | 8.625 | 0.148 | 0.322 | 0.500 |

| 10" | 10.750 | 0.165 | 0.365 | 0.500 |

| 12" | 12.750 | 0.180 | 0.375 | 0.500 |

Incoloy 825 Pipe Weight Chart

| NPS (in) | OD (mm) | Sch 40 Weight | Sch 80 Weight |

|---|---|---|---|

| 1/2" | 21.3 | 1.27 | 1.62 |

| 3/4" | 26.7 | 1.69 | 2.20 |

| 1" | 33.4 | 2.50 | 3.24 |

| 1 1/2" | 48.3 | 4.05 | 5.41 |

| 2" | 60.3 | 5.44 | 7.48 |

| 3" | 88.9 | 11.29 | 15.27 |

| 4" | 114.3 | 16.07 | 22.32 |

| 6" | 168.3 | 28.26 | 42.56 |

| 8" | 219.1 | 42.55 | 64.63 |

| 10" | 273.0 | 60.31 | 81.53 |

| 12" | 323.9 | 79.73 | 108.97 |

Types of Incoloy 825 Pipes & Tubes

Applications of Incoloy 825 Pipes & Tubes

Incoloy 825 pipes and tubes are extensively used in:

- Chemical & Petrochemical Processing Plants

- Sulfuric and Phosphoric Acid Handling Systems

- Offshore Oil & Gas Platforms

- Heat Exchangers & Condensers

- Pollution Control & Scrubber Units

- Nuclear Fuel Reprocessing Equipment

These applications demand materials capable of resisting aggressive corrosion while maintaining mechanical reliability over extended service life.

Looking to Buy Alloy 825 Tubing?

Get project-ready pricing, mill test certificates, and fast delivery across the USA.

Request a Quote!

Related Products

.webp)