Inconel 718 Tube and Alloy 718 Pipe Supplier in USA

We are a leading supplier of Inconel 718 Tube and Alloy 718 Pipe, based in USA. Inconel 718 Tube provides excellent tensile strength, fatigue, and fracture resistance. Inconel 718 Seamless Tube has an important creep resistance in high temperature, which works as high as 700 o C. This alloy is hailed as one that is easy to weld, has a high corrosion resistance and is heat treatment contained. Inconel 718 tubing is good to use in high temperature systems because of its greater resistance to temperature making it suitable in operation in gas turbines, in aerospace components, pumps and measurement probes in energy and process technologies.

Alloy 718 Tube is used in high temperature strength and pitting resistance, corrosion and erosion resistance in a broad spectrum of organic and mineral acids, sulfides, and chlorides. Examples of cold-drawn tubing we frequently make are Inconel 718 Pipe made to such specifications as AMS 5589 and AMS 5590. The Alloy 718 Seamless Tube is strictly handled and checked during the drawing procedure and is of the same quality.

ASTM B516 Inconel 718 Tube has two main applications namely structural and those who need specific outside diameter. UNS N07718 Tubing is readily joined through either of the standard techniques such as flaring, brazing, or coupling or by 718 Alloy tube fittings to high-standard assemblies. Our product is 718 Alloy Polish Tubing, end finishes to custom. We also have welded and seamless Inconel 718 tubes of ASTM specification, in sizes to fit applications such as heat exchangers and condensers. For a full list of our high-performance products, browse our Inconel Pipes & Tubes selection.

Table of Contents

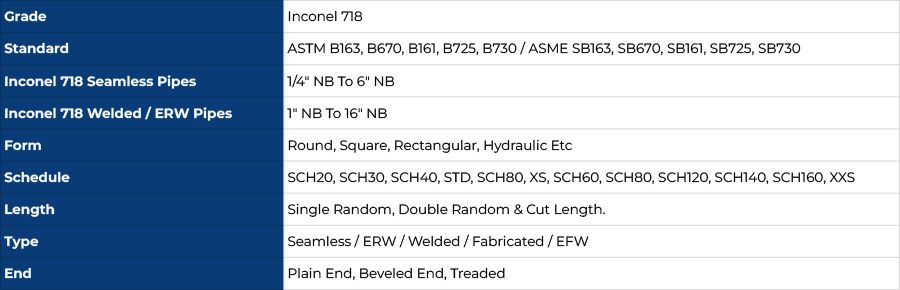

- Inconel 718 Pipes & Tubes Specifications

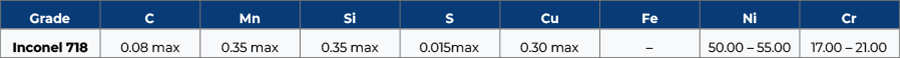

- Chemical Composition of Inconel 718 Tubes

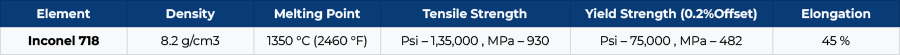

- Mechanical Properties of Inconel 718 Pipes & Tubes

- Physical Properties of Alloy 718 Tube

- Equivalent Grades for Inconel 718 Tubes

- Dimensions of Inconel 718 Pipes & Tubes

- Inconel 718 Tube Stock

- Applications of Inconel 718 Pipes & Tubes

- Inconel 718 Tube Price

Inconel 718 Pipes & Tubes Specifications

Request Your Inconel 718 Pipes & Tubes Quote Today!

Chemical Composition of Inconel 718 Tubes

Mechanical Properties of Inconel 718 Pipes & Tubes

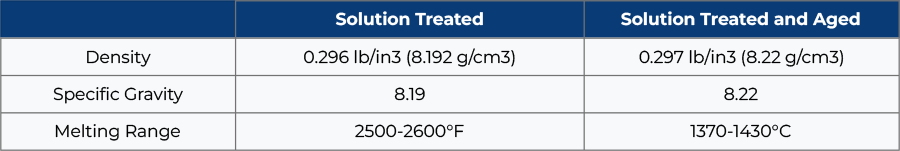

Physical Properties of Alloy 718 Tube

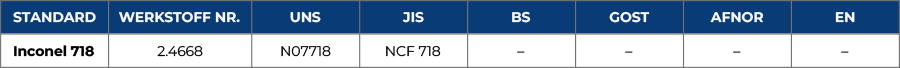

Equivalent Grades for Inconel 718 Tubes

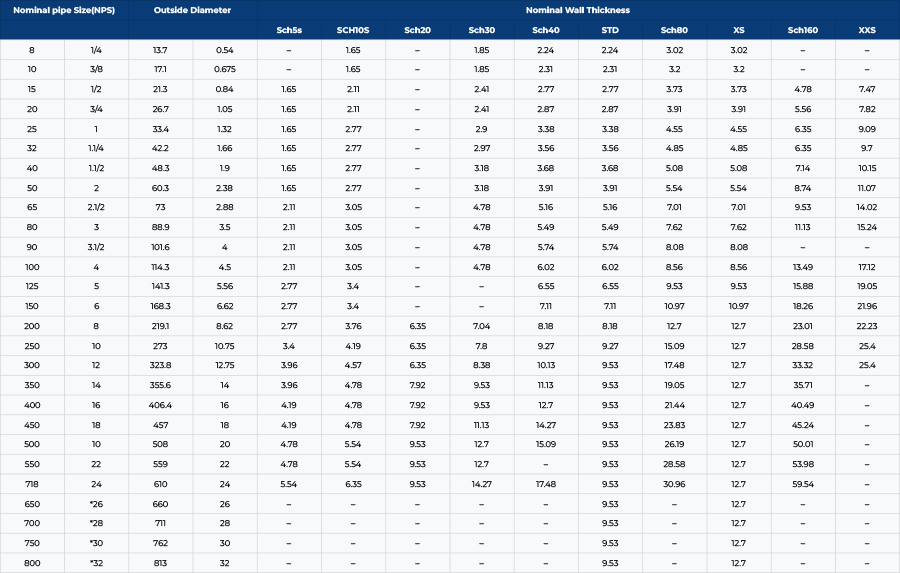

Dimensions of Inconel 718 Pipes & Tubes

Inconel 718 Tube Stock

Inconel 718 Coiled Tubing

Inconel 718 Capillary Tube

Inconel 718 ‘U’ Shaped tubing

Inconel 718 Gas Tube Ar 15 supplier

Inconel 718 seamless tubing

Inconel 718 Thin Wall tube

Inconel 718 Furnace Tube

Inconel 718 Gas Tube

Inconel 718 Heat Exchanger Tubes

Inconel 718 boiler tube

Inconel 718 welded tubing

Inconel 718 Square Tube

Alloy 718 Square Tube (Radius Corners)

Inconel 718 Rectangle Tube

Inconel 718 tubing

Applications of Inconel 718 Pipes & Tubes

- Jet Engines and Rockets: Used inside planes and rockets because they are super strong and don't melt or break, even when things get extremely hot (up to 700 degrees C).

- Deep Sea Drilling (Oil & Gas): Used for equipment buried deep underground and underwater. They resist saltwater and chemicals like sulfur that would quickly destroy normal steel.

- Power Plants (Nuclear): Used for parts inside nuclear reactors and steam generators. They resist heat, pressure, and special kinds of damage that happen inside these plants.

- Chemical Factories: Used to hold and move very harsh, corrosive chemicals and hot acids because the metal doesn't rust or weaken easily.

Related Products

Inconel 718 Tube Price

| Inconel 718 Tube Price per Kg | Price in USD |

|---|---|

| 718 Alloy Tube Price in India | $46 per kg |

| Alloy 718 Tube Price in Japan | $51 per kg |

| UNS N07718 Tube Price in UK / Europe | $54 per kg |

| Alloy WERKSTOFF NR. 2.4668 Tube Price in USA | $65 per kg |

Request Your Inconel 718 Pipes & Tubes Quote Today!

.webp)