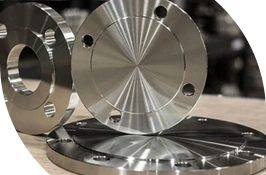

ASTM A105 Carbon Steel Flanges Manufacturer, Supplier & Exporter in USA

ASTM A105 carbon steel flanges are forged pressure-containing components that are in popular service in high temperature and pressure piping. These are manufactured from carbon steel forgings in the form of flanges which are usually delivered according to ASME B16.5 and ASME B16.47 dimensional specifications.

As a manufacturer, supplier, and exporter of ASTM A105 flanges in the USA, USA Piping Solution provides forged carbon steel flanges to refineries, oil and gas pipelines, power plants, petrochemical facilities and industrial piping systems where the requirements are essentially on flange strength, reliability, and dimensional accuracy.

What is ASTM A105 Flange?

ASTM A105 is a material specification that encompasses forged carbon steel flanges, fittings, valves and others that are used to hold pressure in high-temperature and ambient service. The specification is limited to forged products and does not cover raw materials that include round bars, plates or seamless tubular products which are subsequently machined into piping components.

ASTM A105 allows only 10,000 lbs (4,540 kg) as the maximum mass of any individual forging. Forgings that are above this limit fall under ASTM A266 / A266M.

Looking to buy Carbon Steel Flanges?

Check price of ASTM A694 F65 Flanges & ASTM A350 LF2 Flanges

Table of Contents

- ASTM A105 Carbon Steel Flanges Manufacturing Process

- ASTM A105 Carbon Steel Flanges Specifications

- Chemical Composition ASTM A105 Flanges

- Mechanical Properties of A105 Steel Flanges

- Elongation of ASTM A105 Carbon Steel Flanges

- ASTM A105 Flange Weight Chart

- Carbon Steel ASTM A105 Flanges Price List

- Carbon Steel ASTM A105 Flanges Price List

- ASTM A105 Flanges Pressure Ratings

- ASTM A105 Carbon Steel Flanges Facing Types

- Weight Chart of ASTM A105 Forged Steel Flanges

- Types of ASTM A105 Carbon Steel Flanges

- Applications of ASTM A105 Forged Flanges

- Related Products

- Frequently Asked Questions About ASTM A105 Carbon Steel Flanges

ASTM A105 Carbon Steel Flanges Manufacturing Process

ASTM A105 flanges supplied by us are produced through a controlled forging and machining process to ensure consistent mechanical properties and long service life.

Manufacturing steps include:

- Selection of certified carbon steel billets

- Hot forging using open-die or closed-die forging

- Heat treatment (normalizing as required)

- CNC machining of flange faces and bolt holes

- Dimensional inspection as per ASME standards

- Chemical & mechanical testing

- PMI, hardness testing, and visual inspection

- EN 10204 3.1 Material Test Certificate issuance

This process ensures superior grain structure, strength, and resistance to pressure-related failures.

ASTM A105 Carbon Steel Flanges Specifications

| Parameter | Details |

|---|---|

| Size | 1/2″ to 48″ |

| Specifications | ASME SA182 / ASTM A182 |

| Coating / Surface Treatment | Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized, Anti-rust Paint, Zinc Plated |

| Flange Face Type | Raised Face, Flat Face, Ring Type Joint |

| Pressure Ratings | Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500 |

| Standards | MSS SP44, ANSI B16.47 Series A & B, ANSI B16.5, ASA, API-605, AWWA, Custom Drawings |

Chemical Composition ASTM A105 Flanges

| Element | Composition (%) |

|---|---|

| Carbon | 0.35 max |

| Manganese | 0.60 – 1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10 – 0.35 |

| Copper | 0.40 max |

| Nickel | 0.40 max |

| Chromium | 0.30 max |

| Molybdenum | 0.12 max |

| Vanadium | 0.08 max |

Mechanical Properties of A105 Steel Flanges

| Property | Requirement |

|---|---|

| Tensile Strength | 70 ksi min (485 MPa) |

| Yield Strength | 36 ksi min (250 MPa) |

| Elongation (≥ 7.9 mm wall) | 30% |

| Elongation (round specimen, 4D) | 22% |

| Reduction of Area | 30% min |

| Hardness | 187 HBW max |

Elongation of ASTM A105 Carbon Steel Flanges

| Wall Thickness (in) | Thickness (mm) | Elongation (%) |

|---|---|---|

| 5/16 | 7.9 | 30 |

| 9/32 | 7.1 | 28.5 |

| 1/4 | 6.4 | 27 |

| 7/32 | 5.6 | 25.5 |

| 3/16 | 4.8 | 24 |

| 5/32 | 4.0 | 22.5 |

| 1/8 | 3.2 | 21 |

| 3/32 | 2.4 | 19.5 |

| 1/16 | 1.6 | 18 |

Heat Treatment of ASTM A105 Flanges

ASTM A105 flanges generally do not require heat treatment, except under specific conditions designed to ensure material stability. Heat treatment becomes mandatory for flanges exceeding Class 300, items over 4" NPS that are Class 300 or higher, and flanges of special design where the design pressure or temperature is unspecified.

Applied Heat Treatment Methods

When the criteria above are met, one of the following heat treatment methods must be applied to the material:

- Annealing: Heating the flange to a specific temperature and cooling it slowly to soften the metal and improve ductility.

- Normalizing: Heating the steel to a critical temperature followed by air cooling to refine the grain structure.

- Normalize and Temper: A two-step process where the material is normalized and then reheated to a lower temperature to increase toughness.

- Normalize and Quench and Temper: A rigorous process involving normalizing, rapid cooling (quenching), and then tempering to achieve specific mechanical properties.

Hardness Requirements

Heat treatment is critical for achieving the required mechanical properties. ASTM A105 flanges must maintain a Brinell hardness (HB) value between 137 and 187. Any flange found to be outside of this mandatory hardness range shall be rejected to ensure the safety and integrity of the piping system.

ASTM A105 Flange Weight Chart

| Class | Nominal Pipe Size | Slip On | Threaded | Socket Weld | Lap Joint | Blind | Weld Neck |

|---|---|---|---|---|---|---|---|

| 150 lb | 1/2 | 1 | 1 | 2 | 1 | 2 | 2 |

| 3/4 | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Carbon Steel ASTM A105 Flanges Price List

The prices for ASTM A105 flanges vary based on size, pressure rating, and specific configuration. Below is a summary of the current market rates for forged carbon steel flanges:

| Description | ASTM A105 Flange Price in India |

|---|---|

| ASTM A105 / ASME B16.5 Forged Welding Neck Slip On Steel Flange | US $ 0.2 – 100 / Piece |

| Bride Welding Neck RF Flange ASTM A105 Class 150 / Class 300 | US $ 1 – 300 / Piece |

| ASTM A105 Class 150 Loose Plate Lap Joint Flange | US $ 1 / Piece |

| ASTM A105 20# Carbon Steel Flange | US $ 5 – 6.5 / Piece |

| ASTM A105 Forged RF Flange | US $ 1 – 1000 / Piece |

| WN RF Blind Flange 150# ASTM A105 ANSI / ASME B16.5 | US $ 1 – 10 / Piece |

| ASME B16.5 ASTM A105 Carbon Steel Class 150 RF Socket Weld Flange | US $ 0.2 / Piece |

ASTM A105 Blind Flange Dimensions Chart

| Ø | D | b | g | k | Holes | l | Kg |

|---|---|---|---|---|---|---|---|

| 1/2" | 88.9 | 11.1 | 34.9 | 60.3 | 4 | 15.9 | 0.400 |

| 3/4" | 98.4 | 12.7 | 42.9 | 69.8 | 4 | 15.9 | 0.700 |

| 1" | 107.9 | 14.3 | 50.8 | 79.4 | 4 | 15.9 | 0.900 |

| 1¼" | 117.5 | 15.9 | 63.5 | 88.9 | 4 | 15.9 | 1.300 |

| 1½" | 127.0 | 17.5 | 73.0 | 98.4 | 4 | 15.9 | 1.600 |

| 2" | 152.4 | 19.0 | 92.1 | 120.6 | 4 | 19.0 | 2.600 |

| 2½" | 177.8 | 22.2 | 104.8 | 139.4 | 4 | 19.0 | 4.100 |

| 3" | 190.5 | 23.8 | 127.0 | 152.4 | 4 | 19.0 | 5.000 |

| 3½" | 215.9 | 23.8 | 139.7 | 177.8 | 8 | 19.0 | 6.400 |

| 4" | 228.6 | 23.8 | 157.2 | 190.5 | 8 | 19.0 | 7.100 |

| 5" | 254.0 | 23.8 | 185.7 | 215.9 | 8 | 22.2 | 9.000 |

| 6" | 279.4 | 25.4 | 215.9 | 241.3 | 8 | 22.2 | 11.800 |

| 8" | 342.9 | 28.6 | 269.9 | 298.4 | 8 | 22.2 | 21.000 |

| 10" | 406.4 | 30.2 | 323.4 | 361.9 | 12 | 25.4 | 30.000 |

| 12" | 482.6 | 31.7 | 381.0 | 431.8 | 12 | 25.4 | 45.000 |

| 14" | 533.4 | 34.9 | 412.7 | 476.2 | 12 | 28.6 | 59.000 |

| 16" | 596.9 | 36.5 | 469.9 | 539.9 | 16 | 28.6 | 79.000 |

| 18" | 635.0 | 39.7 | 533.4 | 577.8 | 16 | 31.7 | 97.000 |

| 20" | 698.5 | 42.9 | 584.2 | 635.0 | 20 | 31.7 | 124.000 |

| 22" | 749.3 | 46.0 | 641.2 | 692.1 | 20 | 34.9 | 151.000 |

| 24" | 812.8 | 47.6 | 692.1 | 749.3 | 20 | 34.9 | 188.000 |

ASTM A105 Flanges Pressure Ratings

| Temp. °C | Working Pressure by Classes (bar) | ||||||

|---|---|---|---|---|---|---|---|

| 150 | 300 | 400 | 600 | 900 | 1500 | 2500 | |

| -29 ~ 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233.0 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219.0 | 365.0 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313.0 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23.0 | 30.7 | 46.0 | 69.0 | 115.0 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

ASTM A105 Carbon Steel Flanges Facing Types

| American Series | European Series |

|---|---|

| Flat Face (FF) | Type A (Flat Face) |

| Raised Face (RF) | Type B (Raised Face) |

| Tongue (T) | Type C (Tongue) |

| Groove (G) | Type D (Groove) |

| Female (F) | Type E (Spigot) |

| Male (M) | Type F (Recess) |

| Ring Joint Face (RJ) | Type G (O-Ring Spigot) |

| — | Type H (O-Ring Groove) |

Weight Chart of ASTM A105 Forged Steel Flanges

| Standard | Class | Diameter (mm) | Bolt Circle Diameter (mm) | Number of Bolts | Bolt Size | Bolt Hole Diameter (mm) |

|---|---|---|---|---|---|---|

| AS 4087 Flanges | PN14 | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flanges | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | Class 150 | 89 | 60 | 4 | 13 | 16 |

| Class 300 | 95 | 67 | 4 | 13 | 16 | |

| Class 600 | 95 | 67 | 4 | 13 | 16 | |

| Class 900 | 121 | 83 | 4 | 19 | 22 | |

| Class 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 / DIN Flanges | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |

Dimensions of CS ASTM A105n Slip On Flanges

| Standard Organization | Applicable Standards / Codes |

|---|---|

| AMERICAN SOCIETY OF MECHANICAL ENGINEERS (ASME) |

ASME B16.11 – Forged Fittings, Socket Welding and Threaded ASME B16.25 – Buttwelding Ends ASME B16.36 – Orifice Flanges ASME B1.20.1 – Pipe Threads, General Purpose ASME B16.1 – Cast Iron Flanges and Flanged Fittings Classes 25, 125 and 250 ASME B16.5 – Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 ASME B16.47 – Large Diameter Steel Flanges NPS 26 Through NPS 60 ASME B46.1 – Surface Texture (Surface Roughness, Waviness, and Lay) ASME B31.1 – Power Piping ASME B31.3 – Process Piping |

Types of ASTM A105 Carbon Steel Flanges

We manufacture and supply the following flange types in ASTM A105 material:

- Weld Neck Flanges

- Slip On Flanges

- Blind Flanges

- Socket Weld Flanges

- Threaded Flanges

- Lap Joint Flanges

Facing options include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ).

ASTM A105 vs ASTM A350 LF2 vs ASTM A182 Flanges

| Property | ASTM A105 | ASTM A350 LF2 | ASTM A182 |

|---|---|---|---|

| Material Type | Carbon Steel | Low-Temp Carbon Steel | Stainless Steel |

| Temperature Service | High / Ambient | Low Temperature | High / Corrosive |

| Impact Testing | Not Required | Mandatory | Not Mandatory |

| Typical Applications | Refineries, Power Plants | Cryogenic Lines | Chemical Processing |

Applications of ASTM A105 Forged Flanges

ASTM A105 carbon steel flanges are commonly used in:

- Oil & gas transmission pipelines

- Petrochemical and refinery piping

- Power generation plants

- Boiler and pressure vessel connections

- Industrial fluid handling systems

Testing, Certification & Inspection

Each ASTM A105 flange is supplied with:

- Chemical & mechanical test reports

- PMI and hardness testing

- Dimensional inspection

- EN 10204 3.1 certification

- Third-party inspection (SGS / TUV / BV) upon request

Why Choose USA Piping Solution for ASTM A105 Flanges?

- ISO 9001 certified manufacturer

- In-house forging and CNC machining

- Full material traceability

- Competitive pricing for bulk orders

- Export packaging with damage protection

- Supplying ASTM A105 flanges across USA, Europe, and the Middle East

Related Products

Looking for reliable piping solutions tailored to your project requirements? USA Piping Solution offers competitive pricing and international delivery on all ASTM A105 forged components.

Click Here to Request Your Free Quote Today! We respond within 24 hours with the most economical pricing options available.

Request for a QuoteFrequently Asked Questions About ASTM A105 Carbon Steel Flanges

What is the ASTM A105 flange?

ASTM A105 flanges are parts made from forged carbon steel. They are specifically designed for use in pressure systems that operate at normal (ambient) or high temperatures. These flanges are manufactured to meet several international standards, including ASME B16.5, B16.47, and B16.48.

What is the difference between ASTM A106 and ASTM A105?

The primary difference between these two materials is their form and carbon content. ASTM A105 is a forged material used for components like flanges and has a maximum carbon content of 0.35%, which results in higher tensile strength and a better yield point. In contrast, ASTM A106 is a standard for seamless carbon steel pipes with a slightly lower carbon limit of 0.30%, making the pipes more flexible and easier to work with in complex piping layouts.