ASTM A350 LF2 Low Temperature Carbon Steel Flanges Manufacturer in USA

ASTM A350 LF2 flanges are forged low-temperature carbon steel flanges that are used in pressure-containing piping systems and that are subjected to cold and sub-zero services. These flanges are designed to endure brittle fracture in the low temperature of the structural integrity. USA Piping Solution is a reliable manufacturer, supplier, and exporter of ASTM A350 LF2 flanges that produces fully impact-tested flanges that meet ASTM A350 and ASME SA 350 requirements.

A350 LF2 flanges are designed with great toughness of notch, mechanical strength, and stability in dimensional behavior to resist brittle fracture. They are widely used in oil and gas pipelines, LNG plants, cryogenic systems, petrochemical plants, and offshore installations, and low-temperature operation is essential to the safety of the operation.

What is ASTM A350 LF2 Material?

SA 350 LF2 material is a carbon steel forging that is of the type set under ASTM A350, which was designed to be of low temperature pressure service. LF2 (Low Temperature, Grade 2) means that the material has to pass compulsory Charpy V-Notch impact tests, meaning that it has to be tough enough at lower temperatures.

In contrast to standard grades of carbon steel, ASTM A350 LF2 flanges do not lose ductility and impact resistance even at freezing temperatures. This quality helps to greatly reduce the chances of brittle failure and LF2 material can be considered as the most favourable choices of piping systems in cold environments.

Looking to Buy ASTM A350 LF2 Flanges?

Get a competitive A350 LF2 flanges price quotation in the USA with full technical documentation and fast delivery.

Table of Contents

- ASTM A350 LF2 Flange Specifications

- Chemical Composition of SA 350 LF2 Material

- ASTM A350 LF2 Flange Mechanical Properties

- Types of ASTM A350 LF2 Flanges

- Difference Between ASTM A350 LF2 and ASTM A105 Flanges

- What is the Difference Between Class 1 and Class 2 A350 LF2?

- Applications of ASTM A350 LF2 Flanges

- Manufacturing Process of ASTM A350 LF2 Flanges

ASTM A350 LF2 Flange Specifications

| Specification | Details |

|---|---|

| Material Grade | ASTM A350 LF2 / ASME SA 350 LF2 |

| Flange Standards | ASME B16.5 / ASME B16.47 |

| Pressure Classes | 150, 300, 600, 900, 1500, 2500 |

| Sizes | ½” to 48” |

| Facing | RF, FF, RTJ |

| Manufacturing Process | Forged |

| Mandatory Testing | Charpy V-Notch Impact Test |

| Service Temperature | Low temperature applications |

Chemical Composition of SA 350 LF2 Material

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.30 |

| Manganese (Mn) | 0.60 – 1.35 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Silicon (Si) | 0.15 – 0.30 |

| Nickel (Ni) | ≤ 0.40 |

ASTM A350 LF2 Flange Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 480 – 655 MPa |

| Yield Strength | ≥ 240 MPa |

| Elongation | ≥ 22% |

| Impact Test | Mandatory (Charpy V-Notch) |

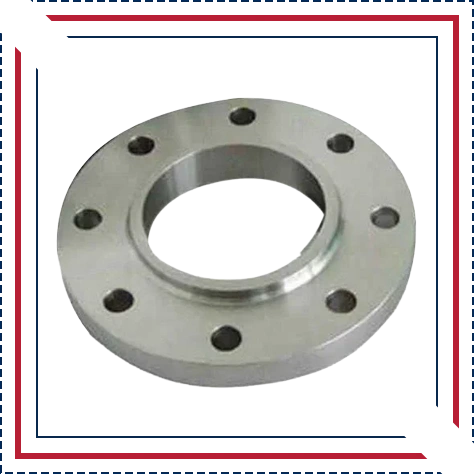

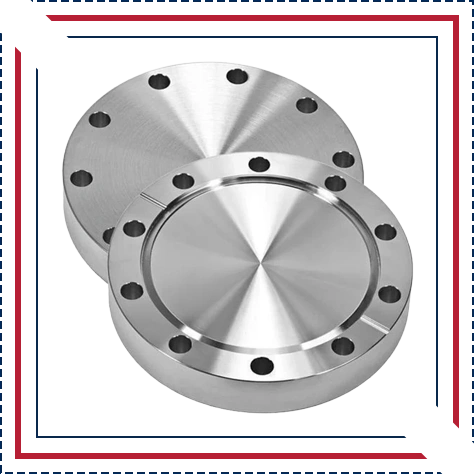

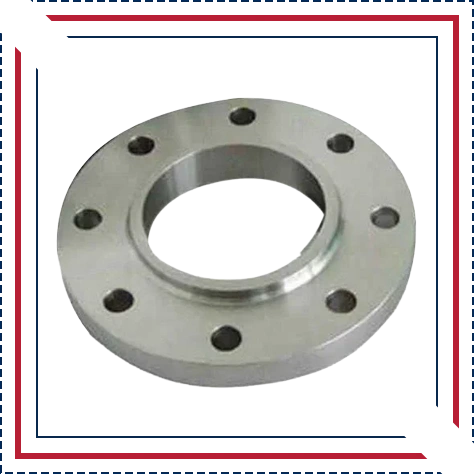

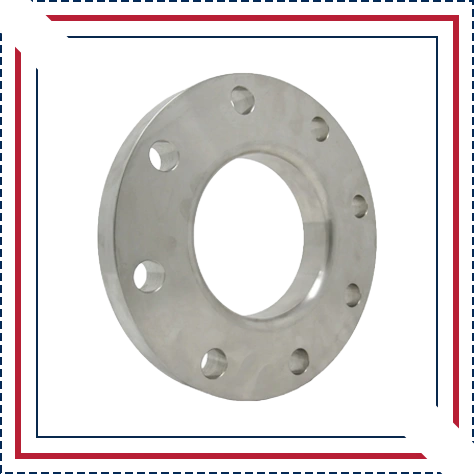

Types of ASTM A350 LF2 Flanges

We manufacture and supply a complete range of A350 LF2 flanges, including

ASTM A350 LF2 Weld Neck Flanges

ASTM A350 LF2 Slip On Flanges

ASTM A350 LF2 Blind Flanges

ASTM A350 LF2 Socket Weld Flanges

ASTM A350 LF2 Lap Joint Flanges

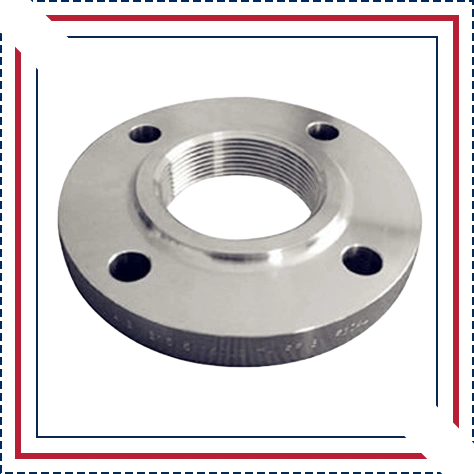

ASTM A350 LF2 Threaded Flanges

All A350 LF2 flanges are supplied with EN 10204 3.1 Mill Test Certificates, ensuring full material traceability.

Difference Between ASTM A350 LF2 and ASTM A105 Flanges

The primary difference between ASTM A350 LF2 and ASTM A105 flanges lies in their intended service temperature and toughness requirements. ASTM A105 flanges are designed for high-pressure and high-temperature applications operating at ambient conditions, where low-temperature impact resistance is not required. In contrast, ASTM A350 LF2 flanges are specifically engineered for low-temperature and cold environment service, with mandatory impact testing to ensure resistance to brittle fracture. For pipelines or systems exposed to freezing or sub-zero temperatures, A350 LF2 is the safer and more reliable choice.

What is the difference between Class 1 and Class 2 A350 LF2?

ASTM A350 LF2 Class 1 and Class 2 differ mainly in their notch toughness and impact test temperature requirements. Class 1 material requires Charpy V-notch impact testing at a minimum temperature of –46°C, making it suitable for general low-temperature applications. Class 2 material, however, is tested at a much lower temperature of –101°C, providing significantly higher impact toughness. Due to this enhanced performance, Class 2 SA 350 LF2 flanges are used in more severe low-temperature and cryogenic applications where Class 1 material may not be sufficient.

Applications of ASTM A350 LF2 Flanges

ASTM A350 LF2 flanges are widely used in low-temperature and cryogenic pipeline systems, where resistance to brittle fracture is critical. These flanges are commonly installed in oil & gas facilities, LNG plants, and petrochemical processing units. They are also used in offshore drilling platforms, refineries, power generation projects, pressure vessels, condensers, and heat exchangers, where dependable sealing and mechanical strength are required under cold operating conditions. Their excellent impact resistance makes them ideal for cryogenic storage tanks and cooling systems.

Manufacturing Process of ASTM A350 LF2 Flanges

Melting Process

The steel used for manufacturing ASTM A350 LF2 flanges is produced using controlled primary melting processes such as open-hearth, basic oxygen, electric-furnace, or vacuum-induction melting (VIM). To enhance material cleanliness, toughness, and chemical uniformity, the primary melting process may include additional refining or degassing treatments. In critical low-temperature applications, secondary remelting techniques such as electroslag remelting (ESR) or vacuum arc remelting (VAR) may be employed to further improve impact resistance and metallurgical consistency.

Discard and Material Soundness

During the production of ASTM A350 LF2 forgings, a sufficient amount of material discard is applied to eliminate any internal defects such as piping, segregation, or inclusions. This ensures that only sound, homogeneous material with uniform mechanical properties is used for flange manufacturing, which is essential for maintaining reliability in low-temperature pressure systems.

Forging Process

ASTM A350 LF2 flanges are manufactured exclusively through the forging process, using raw material in the form of ingots, billets, blooms, slabs, or bars. Forging refines the grain structure and improves directional strength, resulting in superior mechanical properties compared to cast products. This process enhances toughness, fatigue resistance, and pressure-handling capability, making forged A350 LF2 flanges suitable for demanding low-temperature applications.

Heat Treatment

After hot working, the forgings are allowed to cool below the transformation temperature range before undergoing final heat treatment. Depending on design and application requirements, ASTM A350 LF2 forgings are heat treated by normalizing, normalizing and tempering, or quenching and tempering to achieve the specified mechanical and impact properties. These controlled heat treatment cycles ensure consistent strength, ductility, and notch toughness across all flange sizes.

Hydrostatic Testing

Hydrostatic testing of ASTM A350 LF2 flanges is performed in accordance with ASTM A350 / ASME SA350 requirements when Supplementary Requirement S57 of ASTM A961/A961M is specified. The test pressure is applied based on the pressure rating of the finished flange to verify structural integrity and leak-tight performance. Such testing provides additional assurance for flanges used in critical low-temperature and high-pressure piping systems.

Why Choose USA Piping Solution?

- Manufacturer & global exporter

- Strict ASTM / ASME compliance

- Low-temperature impact tested flanges

- Competitive pricing

- Fast delivery worldwide

- Custom sizes & pressure classes available

We supply project-ready ASTM A350 LF2 flanges with complete quality documentation.

Get a Quote for ASTM A350 LF2 Flanges

Looking for reliable ASTM A350 LF2 flange suppliers?

Contact USA Piping Solution today for pricing, datasheets, or technical support.

Request for a Quote

Frequently Asked Questions About ASTM A350 LF2 Flanges

Is the A350 LF2 forged or cast?

ASTM A350 LF2 is a forged metal. This means the steel is heated and hammered or pressed into shape, which makes it much stronger and more reliable than "cast" metal (which is melted and poured into a mold). This specification is specifically used for high-strength piping parts like flanges, valves, and fittings that need to handle intense pressure.

What is the carbon equivalent of ASTM A350 LF2?

The carbon equivalent CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15. For both Class 1 and Class 2 of ASTM A350 LF2, if the maximum thickness of the work piece is less than or equal to 2″, the CE shall not exceed 0.47; if the the maximum thickness of the work piece is greater than 2″, the CE shall not exceed 0.48.

Is LF2 low temperature?

Yes, LF2 is the standard choice for low-temperature service. It is designed to stay tough and resist cracking in freezing conditions, specifically down to -46ºC (-50ºF). While it works great for most cold climates, if you are dealing with extreme cryogenic temperatures (like liquid nitrogen), you would typically upgrade to a nickel-based steel like LF3.