Inconel 601 and Alloy 601 Seamless Tubing Supplier in USA

USA Piping Solution has been a reliable provider of Alloy 601 Tube and Inconel 2.4851 Seamless Tubing in the USA. Inconel 601 is a very diverse nickel-chromium alloy that is used in many industrial systems. The Inconel 601 Pipe, which is composed of high percentage of nickel and chromium, provides it with exceptional resistance to corrosion in multiple mediums as well as oxidation resistance, which is excellent to 2200°F. There is also great resistance to post-weld carburization and graining in the Inconel 601 Tube. These tubes are characterized with high strength, high creep-rupture, good mechanical properties and high hardness. ASTM B775 UNS N06601 grade has been used extensively in such adverse applications as aerospace, chemical processing, power generation, and in such parts as radiant and superheater tubes. Every product of ours comes at affordable rates.

The Alloy 601 Seamless Pipe is easily produced using hot billets. These pipes have a tensile strength of at least 80,000 psi and yield strength of at least 30,000 psi, can be elongated by 30 percent and are easily machined. The UNS N06601 Welded Pipe is made through welding steel sheets or coils. Both forms exhibit a high level of metallurgical stability and spalling resistance especially in high cyclic conditions. The WERKSTOFF NR. 2.4851 Tubing is easily welded, demonstrates an excellent sulfur resistance environment, and is also resistant to acidic cracking resulting in a long service life. Grades that are better in wear and tear resistance are the ASTM B167 UNS N06601 that can be annealed to provide better corrosion protection. At USA Piping Solution, we have skilled workers, modern technology and quality raw materials that we utilize in manufacturing all our product lines.

Nickel Alloy 601 Round Pipe is a designed product with a density of 8.1 g/cm 3 and a melting point of 1320-1370o C. They are easily welded together with the normal welding techniques. Inconel Alloy 601 Heat Exchanger Tube is specially created to be used in high pressure and stress where it cannot be deformed even when hot and cold fluids or gases are subjected to it. In the same way, the Inconel 601 Boiler Tube is most suitable in processing or storing of high pressure and temperature fluids and gases. Our products are all customizable to suit client needs in terms of shape and size. Our large inventory in UNS N06601 Exhaust Tubing and DIN 2.4851 Bright Annealed Tube makes it possible to deliver as fast as we can worldwide. And in case you need an Inconel Pipes & Tubes supplier or any questions, we are available to provide you with more information.

Table of Contents

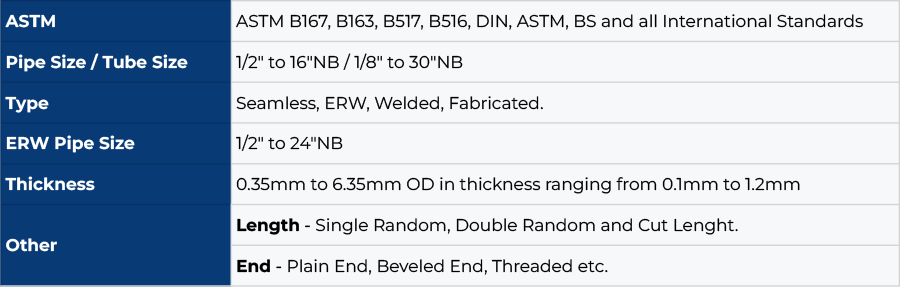

- Inconel 601 Pipes & Tubes Specifications

- Chemical Composition of Inconel UNS N06601 Pipes & Tubes

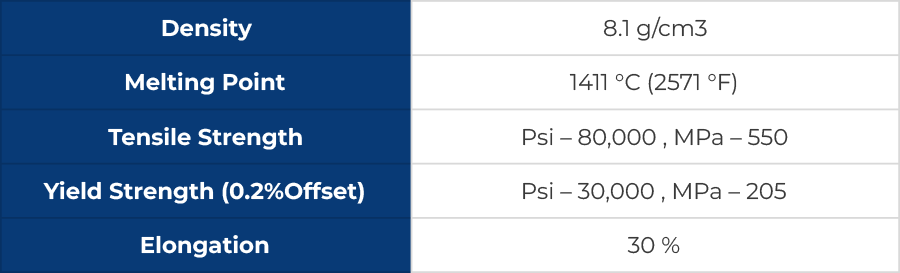

- Mechanical Properties of Inconel 601 Tubes

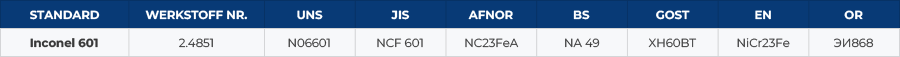

- Inconel 601 Pipes Equivalent Grades

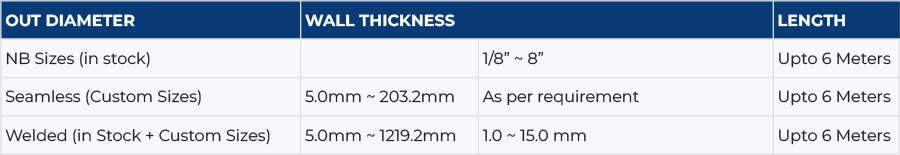

- Inconel 601 Seamless Tube Size

- Applications of Inconel 601 Pipes & Tubes

- ASTM B167 UNS N06601 Inconel 601 Seamless Tube Latest Price List

Inconel 601 Pipes & Tubes Specifications

Request Your Inconel 601 Pipes & Tubes Quote Today!

Chemical Composition of Inconel UNS N06601 Pipes & Tubes

Mechanical Properties of Inconel 601 Tubes

Inconel 601 Pipes Equivalent Grades

Inconel 601 Seamless Tube Size

Applications of Inconel 601 Pipes & Tubes

Related Products

ASTM B167 UNS N06601 Inconel 601 Seamless Tube Latest Price List

Count on USA Piping Solution for all your requirements related to Inconel 601 Alloy Pipes, Inconel 601 Seamless Pipes, Inconel 601 Welded Tubes, and UNS N06601 Tubes. We deliver engineered performance you can depend on, especially when the pressure's on.

Request Your Inconel 601 Pipes & Tubes Quote Today!

.webp)