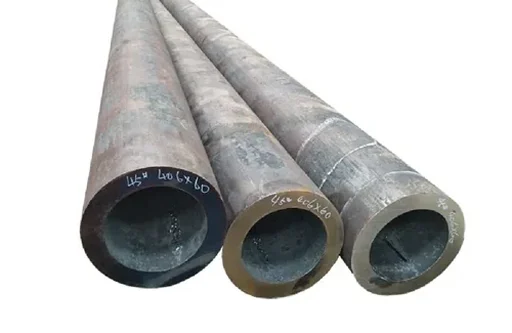

Boiler & Heat Exchanger Tubes

USA Piping Solution is a trusted supplier of seamless and welded Boiler and Heat Exchanger Tubes, delivering precision-engineered solutions for thermal and industrial applications. Our tubes are manufactured from premium carbon and alloy steel materials, complying with strict international standards such as ASTM, ASME and DIN.

Boiler and heat exchanger tubes are vital components across industries like power generation, petrochemicals, and pharmaceuticals because they are specifically designed to endure high temperatures and pressures while ensuring efficient heat transfer and reliable, smooth operation in demanding environments.

Boiler & Heat Exchanger Tube Grades We Offer

We supply a comprehensive range of boiler and heat exchanger tubes that cater to diverse high-pressure and high-temperature applications across industries like power generation, petrochemicals, refineries, and industrial processing. Our tubes are manufactured in compliance with global standards such as ASTM and ASME, ensuring top-tier quality, thermal efficiency, and corrosion resistance.

A210 / SA210 Grade A1 Tubes

View products →

SA179 Tubes / A179 Tubes

View products →

A192 Tubes / SA192 Tubes

View products →

A178 Tubes / SA178 Tubes

View products →

BS 3059 Boiler Tubes

View products →

ASTM A214 SA214 Boiler Tubes

View products →

Boiler Tubes & Pipes

View products →Key Properties of Boiler and Heat Exchanger Tubes

The primary purpose of boiler and heat exchanger tubes is to operate safely and efficiently under extreme conditions. Their key characteristics ensure durability, safety, and efficient performance in power plants, refineries, and industrial heating systems.

- High Thermal Conductivity: These tubes are fundamentally designed to transfer heat efficiently. Materials like copper, stainless steel, and specific alloys are chosen for their superior thermal conductivity, which enables rapid heat exchange and conserves energy.

- Resistance to Extreme Temperatures: The tubes are produced to endure extreme temperatures, often reaching up to 500∘C. This capability is essential in applications like power plants where steam is generated under extremely high heat and pressure.

- Mechanical Durability & Strength: Mechanical durability is critical in high-pressure systems. The tubes must withstand both internal pressure and external mechanical stresses, with seamless variants often chosen for their improved structural integrity.

- Resistance to Oxidation and Corrosion: Tubes must exhibit resistance to oxidation and corrosion for an extended service life.

- Dimensional Accuracy: Precise dimensional accuracy is required to guarantee leak-proof performance.

- Custom Fabrication: Tubes can be customized in different sizes, thicknesses, and materials depending on the industrial application to ensure harmony with specific systems and improve efficiency.

Applications of Boiler & Heat Exchanger Tubes

Boiler Tubes and Heat Exchanger Tubes are used in a wide variety of industrial applications:

- Power Generation & Thermal Plants: Alloy steel tubes are crucial components of main steam lines, reheater and superheater tubes (often Cr/Mo seamless grades), boilers, and feedwater heaters in fossil fuel, nuclear, and combined cycle power plants. The tubes must endure high operating pressures and elevated temperatures, making material strength and long-term reliability essential to prevent failures and ensure safe, steady operations.

- Food and Beverage Manufacturing: These specialized tubes are necessary in the dairy, beverage, and brewing industries, allowing for accurate thermal processing required for pasteurization and sterilization. Engineered for strict hygiene compliance, their anti-microbial surfaces resist fouling while permitting efficient sanitation. Precise temperature control protects product unification, ensuring consistent taste and nutritional value while meeting global food safety regulations.

- Pharmaceutical & Chemical Industries: Seamless stainless-steel heat-exchanger tubing is vital in environments where even minor contaminants can disrupt an entire production run. The polished interior resists buildup, allowing quick Clean-In-Place (CIP) routines. Beyond cleanliness, the chromium-rich alloy resists a range of aggressive solvents and acids, ensuring the piping network remains corrosion-free when manufacturing life-saving medicines or specialty polymers.

- Steam and Industrial Boiler Systems: When boilers fire up, seamless stainless-steel tubing is essential, as its uniform wall thickness eliminates weld seams potential stress points under rapid thermal cycling. Operators can run systems confidently, knowing the pipework will handle temperature swings without cracking. This metallurgy also resists scale adhesion and oxidative wear, meaning fewer shutdowns and a noticeable uptick in cumulative uptime, leading to substantial savings.

Related Products

Get a Quote for Your Boiler & Heat Exchanger Tubes

If you're looking for reliable Boiler and Heat Exchanger Tubes for your projects, contact USA Piping Solution today. We offer tailored solutions for your heat transfer needs and will provide you with a competitive quote based on your project specifications.

Request a Quote!Frequently Asked Questions about Boiler & Heat Exchanger Tubes

What is a heat exchanger in a boiler?

A heat exchanger within a boiler system can be simply described as a long, coiled pipe. The water from your heating system is pumped through this coiled section. As the water passes through, hot exhaust gases (flue gases) from the burner move over the pipe's surface, transferring heat to the water.

What are the tubes used in heat exchangers?

Heat exchanger tubes come in various materials and designs to meet different needs. Common materials include stainless steel, copper and copper alloys, titanium and high-nickel alloys, and carbon or low-alloy steels. They also come in different physical forms, such as tubes with a smooth bore, finned tubes, rifled tubes, or tubes shaped into a U-tube configuration.

What are the types of boiler tube?

Boiler tubes are metal pipes located inside a boiler that heat water to produce steam. There are two primary types of tube boilers: water-tube boilers and fire-tube boilers. In a water-tube boiler, the water flows inside the tubes and is heated by hot gases circulating around the outside.

What is the difference between boiler and heat exchange?

A boiler is the main vessel that holds and heats the water; a bigger boiler can store more steam, and a stronger element heats it faster. When referring to a system that uses a heat exchanger, it often implies a setup designed for highly efficient heat transfer that typically includes a larger boiler and a stronger heating element to manage the energy exchange.

What are boiler tubes made of?

Boiler tubes are typically constructed from alloy steel. This material is composed of carbon steel mixed with other elements like chromium, molybdenum, and nickel to give the tubes the required strength and heat resistance.