ASTM A335 P1 Seamless Pipes Manufacturer, Supplier & Exporter in USA

USA Piping Solution is one of the major manufacturers, exporters, and suppliers of high-quality raw materials of ASTM A335 P1 Seamless Pipes that are produced following global standards. Serving as ASME SA335 Chrome-Moly Pipes, they are ferritic alloy steel pipes that are used in applications where the temperature is high and is known to be durable and with a high service life.

ASTM A335 P1 alloy steel is a low-carbon (0.05–0.15% carbon) steel that is composed of chromium and molybdenum and has high strength, high weldability, and corrosion resistance. It offers tensile strength of 415 Mpa minimum with yield strength of 205 Mpa and elongation is good.

These pipes are either hot-finished or cold-drawn then heat treated to improve its performance. They are suitable in high-temperature applications and are common in oil and gas, boilers, chemical, and petrochemical sectors.

We provide Chrome Moly Seamless Pipes in many forms round, square, rectangular and hydraulic with threaded, beveled or plain-ends to match the application required in various applications within the industry.

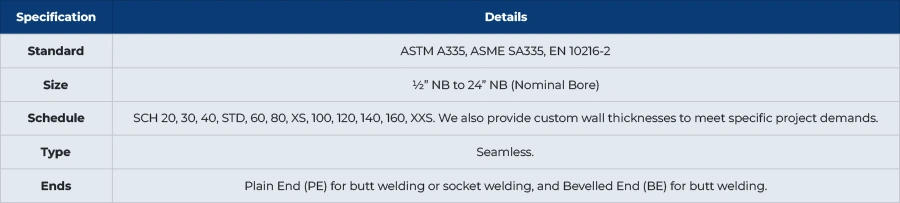

ASTM A335 P1 Seamless Pipes Specifications

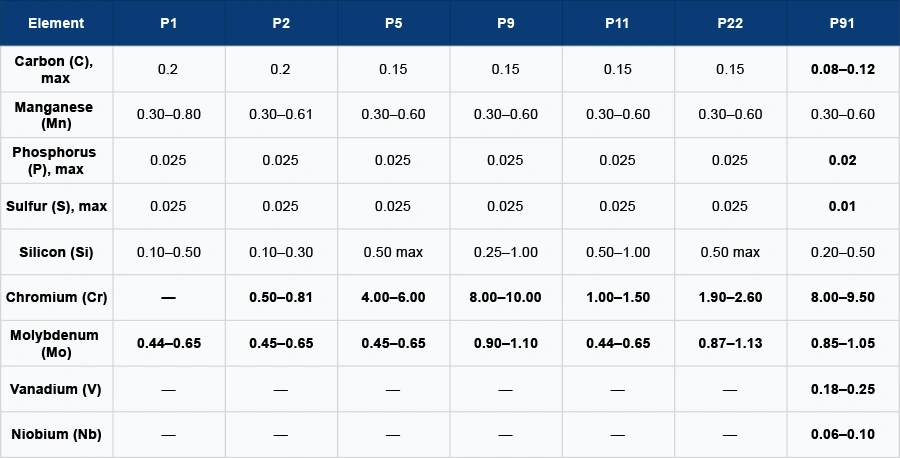

Chemical Composition of ASTM A335 P1 Alloy Steel Seamless Pipes

Mechanical Properties of ASTM A335 Gr. P1 Seamless Pipes

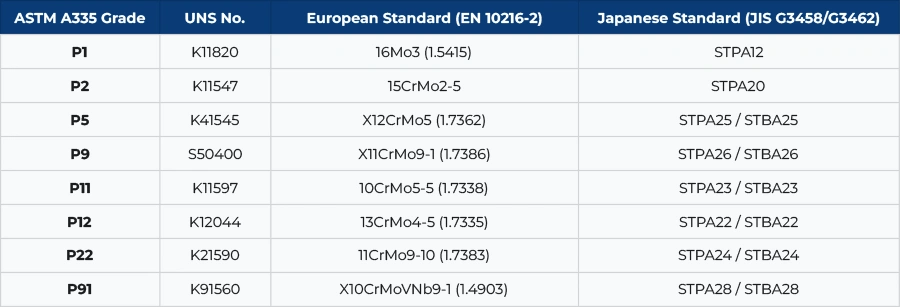

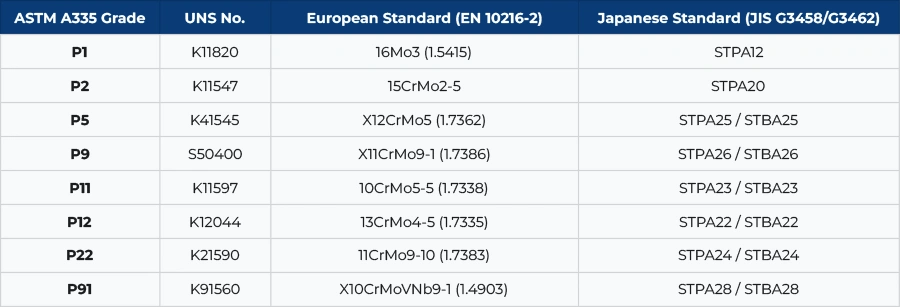

Equivalent Grades of ASTM A335 P1 Seamless Pipes

ASTM A335 P1 Chrome Moly Pipes Outside Diameter & Tolerance

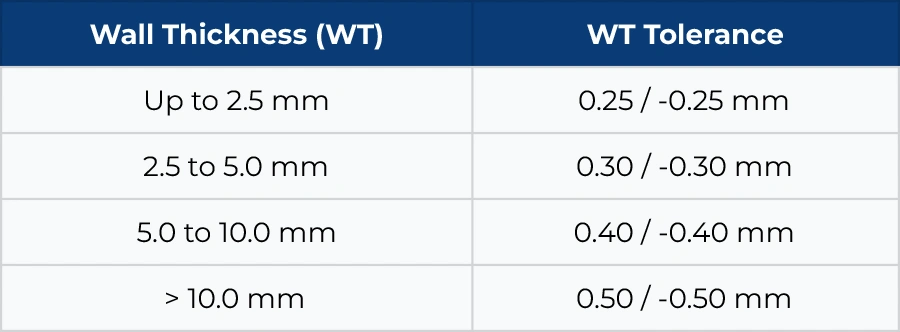

ASTM A335 Seamless Pipes Wall Thickness

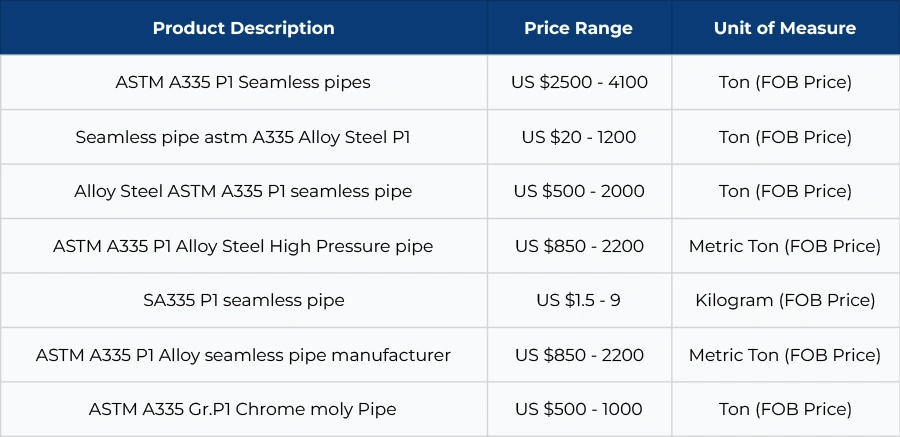

ASTM A335 P1 Seamless Pipe Price

To get an accurate, current price quote for your specific needs, please contact USA Piping Solution directly.

Applications of ASTM A335 P1 Chrome Moly Pipe

ASTM A335 P1 alloy steel pipes find wide-spread service wherever moderately high temperature strength and, cost effectiveness, are a necessity. It is a well-balanced chemistry and mechanical profile that makes P1 appropriate for applications that do not require extremely high creep resistance, but still are looking for a reasonable service life. Some common industries and applications include:

- Power Generation Facilities: Components of piping steam lines, headers and boiler tubes used in steady-state and moderate operating conditions.

- Oil Refineries: Components of heater lines and fluid transfer; piping with economical and performance expectations.

- Chemical and Petro-Chemical: Heat exchanger tubing, process piping and reactor system components needing moderate creep strength and consistently oxidation resistant.

- Industrial Boilers: Boiler tubes and pressure vessels used in medium-pressure steam service.

- General steam distribution systems: Applications in industrial steam lines and auxiliary piping systems.

With P1 pipes, our focus is on value and project consistency. We have become a trusted supplier for industries where standard high-temperature pipelines are required.

Discover the diverse applications and specifications by exploring our complete catalog of Alloy Steel Pipes & Tubes.

Get a Quote for ASTM A335 P1 Seamless Pipes

Looking for ASTM A335 P1 pipes? We offer competitive prices, stock in stock and delivery services on a timely basis to projects of any size. Get a quick personalized quote today and our sales team will provide you with the best quote that suits your needs exactly.

Request a QuoteFrequently Asked Questions About ASTM A335 P1 Seamless Pipes

What is the main difference between ASTM A335 P1 and other P-grades?

ASTM A335 P1 is a low alloy steel, which has very low numbers of elements, mainly Chromium and Molybdenum. It is made to suit high temperature services that need moderate strength and moderate creep, not more aggressive corrosive services or extreme high temperature services that demand alloys of greater strength, such as P11, or P22.

Can ASTM A335 P1 pipes be used in high-pressure systems?

Yes, the ASTM A335 P1 pipes are seamless, meaning there is no welded seam, and a uniform wall thickness throughout the pipe. This provides high potential for loading applications requiring high pressure as would be found in boilers, refineries and power generation systems. The design of seamless pipes is best suited for those applications.

What types of certifications and documentation come with my order?

Every ASTM A335 P1 Alloy Steel Seamless Pipe order from USA Piping Solution comes with full documentation. Please note a seamless pipe - that means there is a Mill Test Certificate (MTC) that provides Chemical Analysis, Mechanical Properties, and if you require third-party inspection documentation these can be included for full traceability.

What is the typical lead time for an order of A335 P1 pipes?

We have a large stock supply of ASTM A335 P1 pipes in our stockyards, and can offer Just in Time deliveries to support urgent projects. With custom orders we can provide timelines depending on the size and scope of your project, our logistics department will make all efforts to deliver your material at the earliest.

Are these pipes suitable for welding?

ASTM A335 P1 is a low-carbon alloy steel that is highly welded. It is however advisable that the relevant welding processes, such as pre heating and heat treatment of the welds after the welding should be applied to maintain the mechanical qualities and avert fractures. One should consult a welding engineer and use the recommended standards.