ASME SA335 P2 Chrome Moly Pipe Manufacturer and Supplier in USA

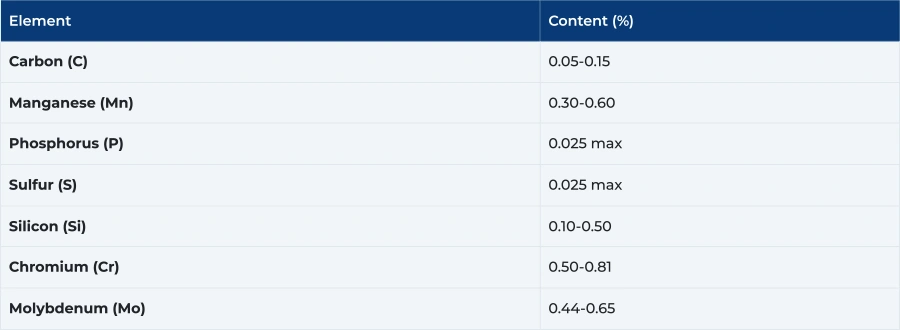

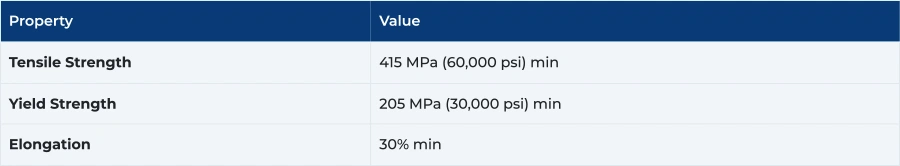

ASTM A335 P2 refers to low-carbon chromium-molybdenum alloy steel. To be more precise, the ASTM A335 P2 Chrome Moly Pipe is a certain chemical composition, namely, it comprises approximately 0.44 percent of molybdenum and 4 percent of chromium and low carbon content 0.015 percent. The low carbon also contributes to the fact that the welding of the material can be easily realized and even without using filler metals and preheating. The alloy has similar strength to other austenitic stainless steel grades like 304 and 316 with a minimum tensile strength of 415 Mpa and minimum yield strength of 205 Mpa. It also contains manganese, phosphorus, sulfur and silicon traces.

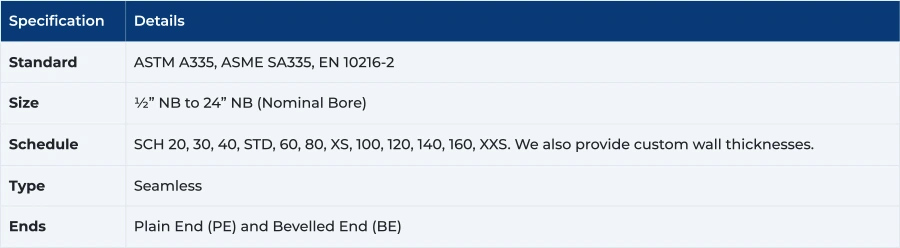

This A335 Gr P2 Pipe has bore sizes of nominal bore size of 1/8NB to 24NB, with wall thicknesses of about 3mm to 12mm. The ASTM A335 P2 Pipes are produced in a range of pressure capacities which range between Sch 20 and XXS. The material is an alloy of ferritic, which can be improved by means of heat treatments including full or isothermal annealing. The Alloy Steel A335 P2 pipe is a round, square, rectangular, and hydraulic tube. Cold drawing or cold rolling is part of the manufacturing processes, with the finished products being offered in individual random, twice random, or cut-to-length sizes, with the pipe ends being finished beveled, plain, or threaded.

The ASTM A335 P2 Alloy Steel Seamless Pipes are made of high quality steel and are manufactured using modern manufacturing technology and in most cases, it is made with a protective chrome layer to guarantee against corrosion and durability. ASTM A335 P2 Seamless Pipe or SA335 P2 Chrome Moly Pipe is a great product and is widely used in high temperature service applications such as petroleum industrial pipelines, heat exchangers, oil and gas transmission systems, and steam service in power plants. The USA Piping Solution operates in the line of a great variety of the ASTM A335 Grade P2 Pipes and deals with the business of the supply of ASTM A335 P2 Welded Pipe as well as the seamless varieties. The manufactures are done according to the international quality standards, and the products are provided with a comprehensive variety of ASTM A335/ASME SA335 P2 High Pressure Steel Pipe at reasonable prices and are used in various industries such as petrochemical, engineering, chemical, and oil and gas.

Table of Contents

- ASTM A335 P2 Pipes Specifications

- Chemical Composition of ASTM A335 P2 Chrome Moly Pipe

- Mechanical Properties of ASTM A335 Grade P2 Pipes

- Equivalent Grades of ASTM A335 P2 Seamless Pipe

- Dimensional Tolerances of A335 Gr P2 Pipe

- Wall Thickness Tolerances of SA335 P2 Chrome Moly Pipe

- ASTM A335 P2 Pipes Heat Treatment

- Applications of A335 P2 Alloy Steel Pipe

- Related Products

ASTM A335 P2 Pipes Specifications

Chemical Composition of ASTM A335 P2 Chrome Moly Pipe

Mechanical Properties of ASTM A335 Grade P2 Pipes

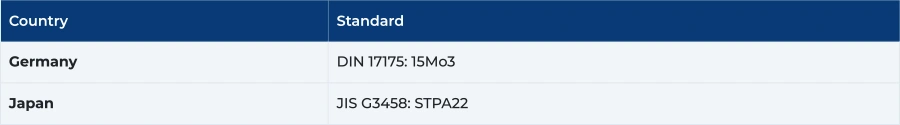

Equivalent Grades of ASTM A335 P2 Seamless Pipe

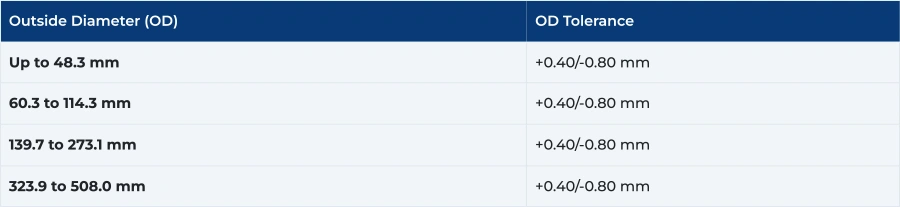

Dimensional Tolerances of A335 Gr P2 Pipe

The dimensional tolerances for our A335 Gr P2 Pipe are strictly controlled to ensure a precise fit in complex piping systems, as detailed by the ASTM A335 standard.

Wall Thickness Tolerances of SA335 P2 Chrome Moly Pipe

The wall thickness of the SA335 P2 Chrome Moly Pipe must meet strict tolerances to maintain the pipe's pressure rating and structural integrity.

ASTM A335 P2 Pipes Heat Treatment

Applications of A335 P2 Alloy Steel Pipes

- Thermal Power Stations: Typically found in superheaters tubes, reheater tubes and high-pressure steam pipes operating above 500 °C.

- Oil Refineries: In vapour-phase service for catalytic reformers, and hydrocrackers, furnace tubes where there is high-pressure hydrogen, and thermal cycling.

- Petrochemical Plants: Where long-term designed service is required such as in process heaters, reactor piping and critical steam systems that must operate reliably under cycling conditions

- Boiler and heat exchangers: High pressure boiler tubes, feedwater systems, and various steam generators where corrosion and creep resistance is essential.

- Chemical processing units: Reactor piping and processing lines where the steam or gaseous service is severely corrosive.

- Industrial Infrastructure: Lifting pipelines within steel, fertilizers and other heavy industrial facilities directly exposed to demanding service.

Related Products

Get a Quote for ASTM A335 P2 Pipes

Looking for ASTM A335 P2 pipes for high-pressure or high-temperature applications? We provide pipes that are tested for quality and certified and we can support your supply requirements globally. Therefore, you can request a quote so we can provide a reliable, project-specific solution.

Request a Quote

Frequently Asked Questions About ASTM A335 P2 Pipes

What is P2 material?

ASTM A335 P2 is a low alloy, medium carbon steel primarily employed in high temperature and mechanical service. It has 0.25-0.55 percent of carbon with an addition of chromium and molybdenum making it a good strength, machinability as well as reliable. It is normally below 250 HB hard.

What is the main difference between ASTM A335 P2 and ASTM A335 P1?

The essential distinction is in the chemical composition of them. Compared to P1, P2 contains slightly more chromium (0.500.81) and molybdenum (0.440.65) which increases its high temperature strength and suitability to the demanding environment.

Is ASTM A335 P2 pipe suitable for high-pressure systems?

Yes, the ASTM A335 P2 pipes are non-seam. This implies that they do not have any welded joints, and thus they have the same wall thickness and high strength. They are perfect in applications where the pressure and temperature are high such as power plants, heat exchangers, and refineries.