ASTM B444 Inconel 625 Pipe Manufacturer & Supplier in USA

USA Piping Solution is one of the leading manufacturers and suppliers of high-quality Inconel 625 Pipes and Tubes within the USA. Inconel 625 Pipe is a better Nickel-Chromium-Molybdenum alloy that is praised because of having a superior corrosion resistance in a wide range of corrosive media, in which it is notably resistant to crevice and pitting corrosion.

Inconel 625 Seamless Pipe is a perfect solution to tougher tasks such as seawater service. It is equal to UNS N06625, W.NR 2.4856, and AWS 012. Our piping with specifications such as SCH40 and SCH60 Inconel 625 Pipe can be used in extreme conditions as well due to its high strength. We boast of being suppliers of Alloy 625 Pipes and welded selections that conform to ASME SB444 and ASME SB725. Inconel Alloy 625 Clad Pipe is commonly used in turbine, heat exchanger, and molding components, it is also commonly specified in critical applications in the offshore chemical processing, oil and gas and nuclear markets.

The Inconel 625 tube is an ideal option to be used in high-strength, high-oscillation-prone regions in extreme temperatures and it has specific use, especially in the aerospace and offshore oil and gas industries. Inconel 625 Seamless Tube is a high-valued product that has shown resistance to pitting, stress corrosion, and corrosion fatigue and is therefore able to retain important mechanical properties to temperatures of 450 0 C. Another common cold-drawn choice is Inconel 625, conducted in tubing that has been produced to meet AMS 5581 requirements. Generally, quality is checked by meticulously inspecting all Inconel 625 boiler tubes during the cold drawing process. The USA Piping Solution has the use of efficient and skilled staff with the use of the latest technology to manufacture dependable products of ASTM B444 UNS N06625.

Looking to buy Hastelloy Pipes & Tubes?

Check price of Hastelloy C276 Tubing in USA

Table of Contents

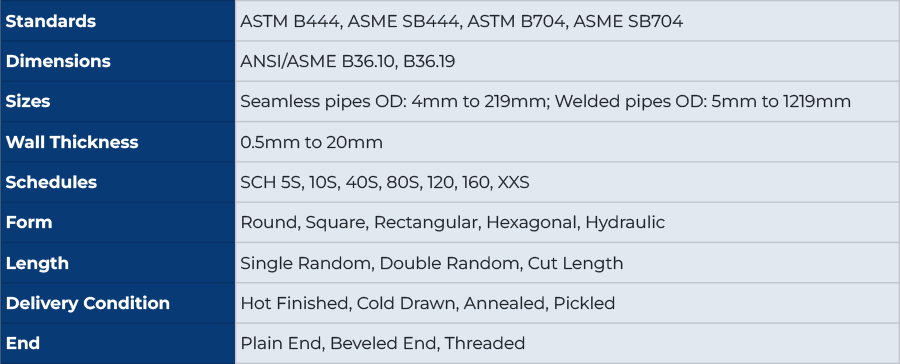

- Inconel 625 Pipes & Tubes Specifications

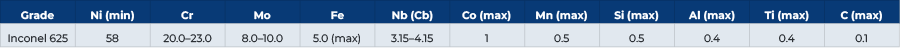

- Chemical Composition of Inconel 625 Pipes & Tubes

- Mechanical Properties of Inconel 625 Pipes & Tubes

- Equivalent Grades for Inconel 625 Pipes & Tubes

- Inconel 625 Pipe Weight Chart (kg/Mtr)

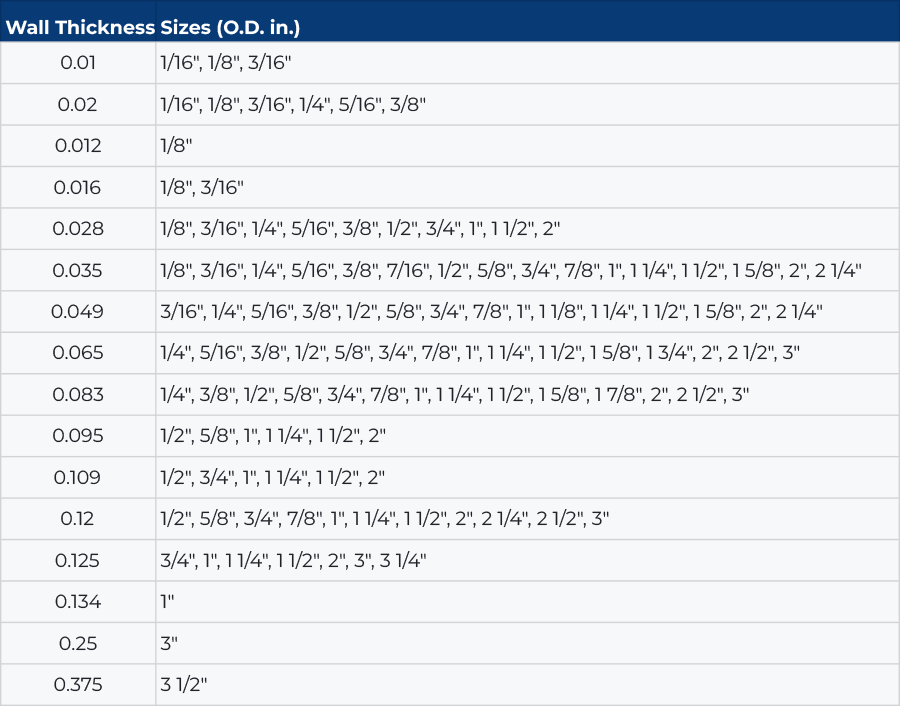

- Inconel 625 Tube Size Chart

- Inconel 625 Tube Pressure Rating

- Applications of Inconel 625 Pipes & Tubes

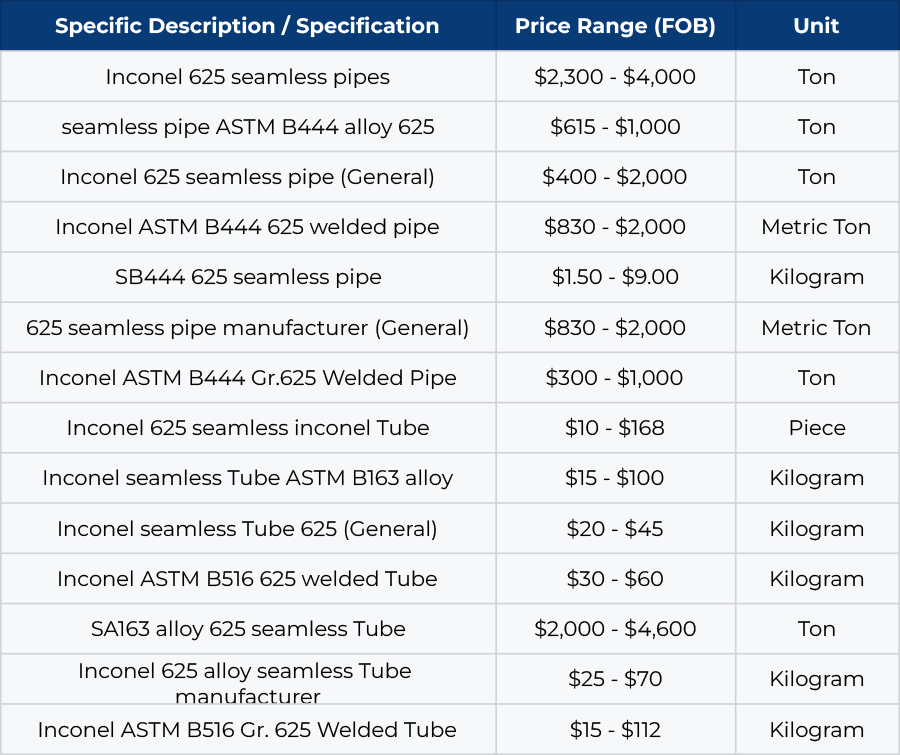

- Inconel 625 Pipe and Tube Price List

Inconel 625 Pipes & Tubes Specifications

Request Your Inconel 625 Pipes & Tubes Quote Today!

Chemical Composition of Inconel 625 Pipes & Tubes

Mechanical Properties of Inconel 625 Pipes & Tubes

Equivalent Grades for Inconel 625 Pipes & Tubes

Inconel 625 Pipe Weight Chart (kg/Mtr)

.png)

Inconel 625 Tube Size Chart

Inconel 625 Tube Pressure Rating

Pipe Pressure Ratings (Working Pressure in psig)

.png)

Tube Pressure Ratings (Maximum Internal Pressure in ksi)

.png)

Applications of Inconel 625 Pipes & Tubes

The superior properties of Inconel 625 make our pipes and tubes a preferred choice in demanding industries, including:

- Aerospace Industry: Used for components like ducting, engine exhaust systems, and thrust reversers due to its high strength-to-weight ratio and resistance to high temperatures.

- Chemical & Petrochemical Processing:It’s used to create areactor vessels, heat exchangers, and pipelines handling aggressive acids and corrosive chemicals.

- Marine and Offshore Engineering:This alloy is built with the feature of excellent corrosion resistance for seawater, which makes it suitable for wire ropes, propeller blades, and sheathing in subsea applications.

- Nuclear Power Generation:Employed for reactor core components and control rod mechanisms due to its excellent resistance to radiation and stress-corrosion cracking.

- Oil & Gas Industry: Critical for sour gas service and other downhole applications where resistance to sulfides and chlorides is essential.

Related Products

Inconel 625 Pipe and Tube Price List

Ready to inquire about our stock of Inconel 625 Pipes, Inconel 625 tubes or any other Inconel Pipes & Tubes? Contact us for a precise quote tailored to your project specifications.

Request a Quote!

.webp)