ASTM A335 P5 pipe is a seamless chrome-moly alloy steel pipe designed for high-temperature and corrosive service environments. This grade has a chemical composition of 4.00%-6.00% chromium and 0.45%-0.65% molybdenum which gives it excellent oxidation, creep strength, and long-term structural stability at higher temperatures. P5 grade chrome-moly pipe is most common in boilers, heat exchangers, power plants and petrochemical systems where there is a need for consistent performance and durability.

ASTM A335 P5 Alloy Steel Seamless Pipe or UNS K41245 is a high-tensile material that is used to form hard rigid corrosion-resistant structures. ASME SA335 Grade P5 Pipe is of high tensile-strength and offers high mechanical properties with annealed material. It exists in many forms, such as round, hydraulic, rectangular, square or hexagonal and is normally provided with an end type of threaded, beveled or plain.

ASTM A335 P5 Seamless Ferritic Alloy Steel Pipes Manufacturer and Supplier

USA Piping Solution has offered ASTM A335 P5 Seamless Pipe that under the ASTM A335 specifications and is made to ASTM as well as ASME and API dimension specifications. We are a manufacturer and a supplier of Seamless and ASME SA 335 Grade P5 ERW Pipe types. These pipes come in a large array of nominal bore sizes of 1/8 inches to 30 inches, schedules of Sch 20-XXS with lengths up to 13500mm, or custom cut-to-length.

Table of Contents

- ASTM A335 P5 Seamless Pipe Specifications

- ASTM A335 P5 Pipe Chemical Composition

- Mechanical Properties of ASTM A335 P5 Alloy Steel Seamless Pipe

- ASTM A335 Alloy Steel Grade P5 Pipes Equivalent Grade

- Heat Treatment for P5 Grade Chrome-Moly Pipe

- ASTM A335 P5 Seamless Pipes Sizes in MM

- Wall Thickness Tolerance Chart for ASTM A335 P5 Pipes

- Applications of ASTM A335 P5 Seamless Pipes

- Types Of ASME SA335 Seamless Pipes

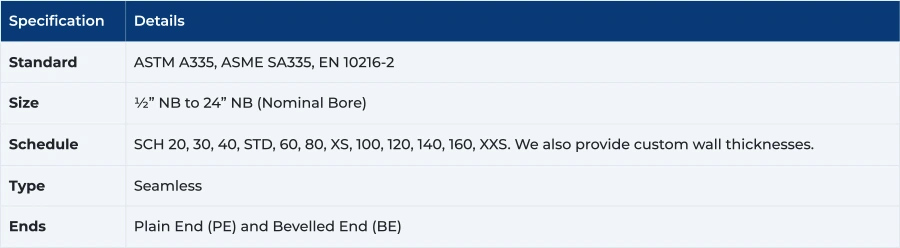

ASTM A335 P5 Seamless Pipe Specifications

ASTM A335 P5 Pipe Chemical Composition

Mechanical Properties of ASTM A335 P5 Alloy Steel Seamless Pipe

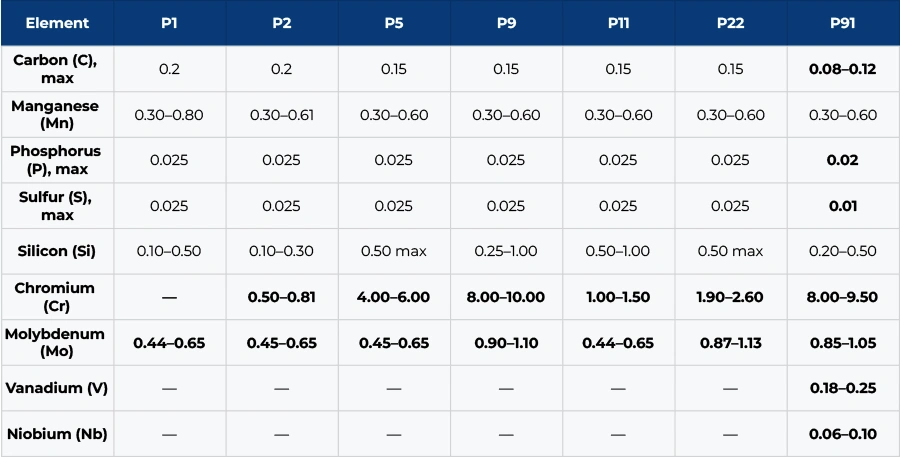

ASTM A335 Alloy Steel Grade P5 Pipes Equivalent Grades

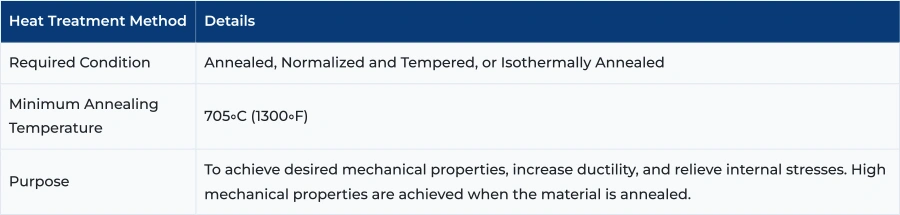

Heat Treatment for P5 Grade Chrome-Moly Pipe

Proper heat treatment is essential for achieving the specified strength and ductility of the A335 P5 Seamless Pipe, with annealing being a common method to relieve internal stress.

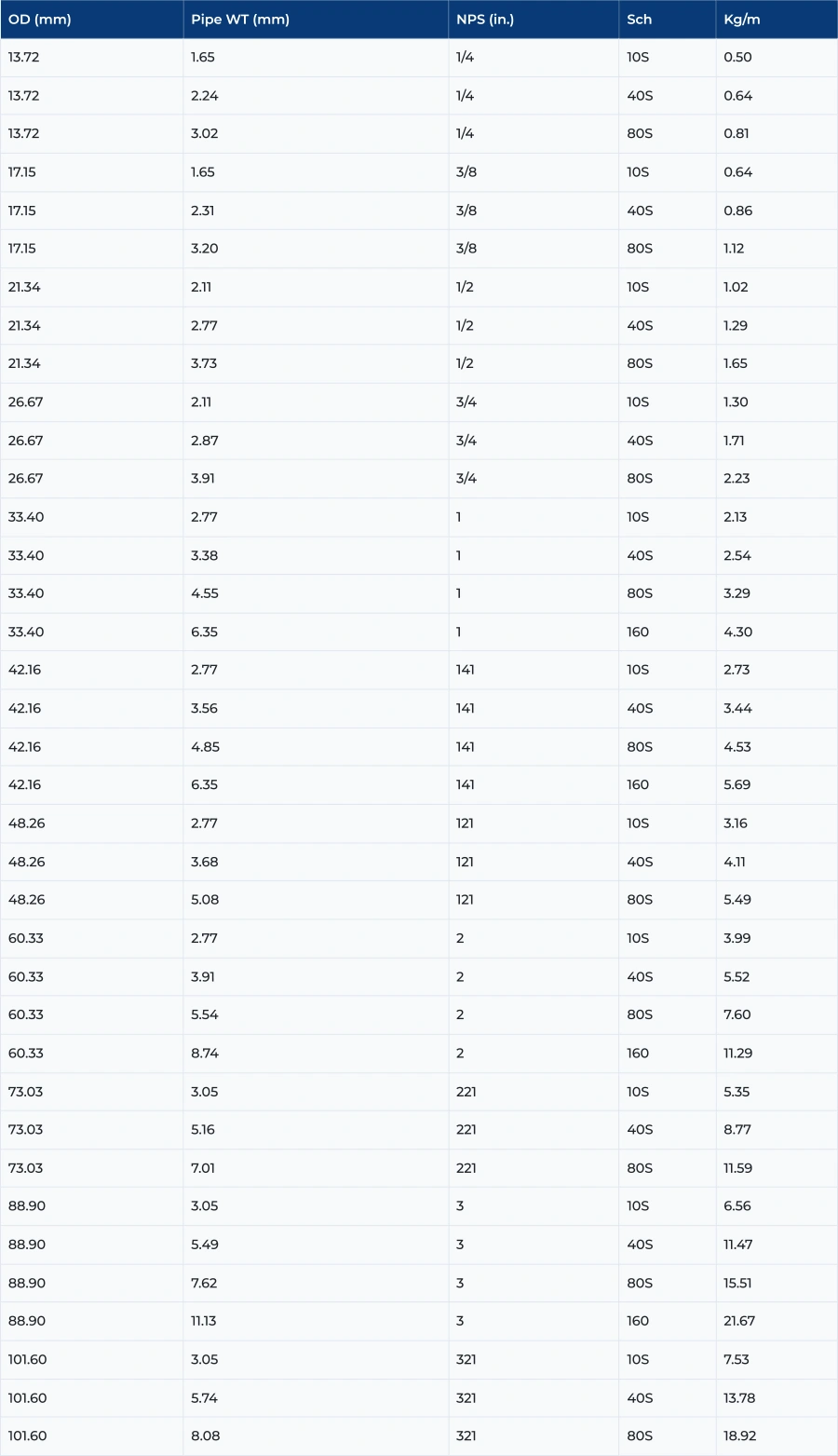

ASTM A335 P5 Seamless Pipes Sizes in MM

The table below describes the typical dimensions of ASTM A335 P5 Seamless Pipes with the Outer diameter (OD) and Wall Thickness (WT) in millimeters and cross tabulated with their nominal inch size and the corresponding Schedule (Sch) number. The last column will give the estimated weight per meter (Kg/m).

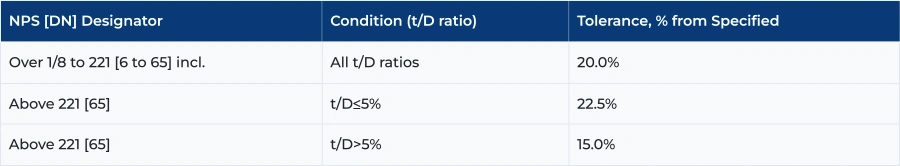

Wall Thickness Tolerance Chart for ASTM A335 P5 Pipes

The table below describes the allowable wall thickness tolerances of ASTM A335 P5 Alloy Steel of the Seamless Pipes which is a percentage deviation of the nominal thickness. The tolerances are according to the Nominal Pipe Size (NPS) and the ratio of defined wall thickness (t) to defined outside diameter (D).

Applications of ASTM A335 P5 Seamless Pipes

- Steam and hot gas systems in power plants: Including superheaters and reheaters.

- Petrochemical process units: For transporting high-temperature fluids in reformers and catalytic crackers.

- Boilers and heat exchangers: Where high oxidation resistance and thermal integrity are essential.

- Furnace piping: Withstanding thermal cycling in heater tubes and radiant coils.

- Oil & gas field equipment: Used in sour service and high-temperature transmission lines.

Find the perfect solution for your project. Our complete catalog details the extensive applications and technical specifications for our Alloy Steel Pipes & Tubes.

Types Of ASME SA335 Seamless Pipes

- ASTM A335 Steel P5 seamless steel pipes steel tube

- Black ASTM A335 P5 Pipes, Size: 1/2 Inch

- 100 mm to 12.5 mtr ASTM A335 P5 Seamless Pipes

- 3m, 12m, 6m, 30m Alloy Steel Pipes ASTM A 335 P5

- Round Alloy Steel ASTM A335 P5 Pipes

- ASTM A335 Gr P5c Pipes 3m

- ASTM A335 P5 Pipe, Size: 1/2 Inch And 3/4 Inch

- 1/2 inch, Round And Square ASTM A 335 P5 Alloy Steel Pipes

- 1/2 " TO 24 " ASTM A335 GR P5 Seamless Pipe

Related Products

Get a Quote for ASTM A335 P5 Pipes Today

Make sure that you can rely on your high-temperature piping systems and make them last longer and be more reliable with ASTM A335 P5 pipes of USA Piping Solution. With a huge inventory, accuracy in machining and efficient logistics worldwide, we are the reliable option when it comes to the supply of chrome-moly pipes. Get in touch with us now to get a quote and our latest best prices to make your procurement of materials streamlined.

Request Your ASTM A335 P5 Pipes Quote Today!