ASTM A53 Seamless Pipe is a carbon steel pipe manufactured with a smooth seam formed by welding, making it clean and free of a weld line (seam). This is designed to be used in pressure and mechanical applications, as well as structural applications that need consistency in strength and reliability. ASTM A53 seamless piping is deployed in industrial piping systems which may be steam, water, gas, air, and other piping systems in which uniform wall thickness and pressure resistance are essential.

ASTM A53 & ASME SA53 Carbon Steel Pipes, ASTM A53 Grade B Seamless Pipe, ASME SA53 Carbon Steel Boiler Tubes and ASTM A53 Steel Stockist in USA

USA Piping is a trusted supplier of Carbon Steel Seamless Pipe, ASTM A53 Grade B ERW Pipes, which is PED certified as well as a supplier of numerous ASTM A53 steel products. Our business is to provide materials which are required in high-performance applications such as in environments with temperature beyond 1750 °F, where the formation of sigma phase is an undesirable phenomenon.

Our products are ASTM A53 Grade B ERW pipes at fair prices and assistance in selecting a suitable grade among the similar ASTM, ASME, and API specifications. You need particular pipe sizes of ASTM A53 seamless or advice regarding the size of ASTM A53 seamless piping, we will supply you with the right size and at the appropriate time.

Contact us today for ASTM A53 Seamless Pipe Price!

Request Quote Now!What Makes ASTM A53 Seamless Pipe Different?

- Manufactured without welding, eliminating seam-related weaknesses

- Better resistance to internal pressure compared to ERW pipes

- Uniform mechanical properties across the pipe body

- Suitable for bending, flanging, coiling, and pressure service

- Preferred for critical services in power plants and refineries

ASTM A53 Seamless vs ERW Pipe

| Feature | Seamless (Type S) | ERW (Type E) |

|---|---|---|

| Manufacturing | No weld seam | Electric resistance welded |

| Pressure handling | Higher | Moderate |

| Wall uniformity | Excellent | Good |

| Use in critical service | Recommended | Limited |

| Cost | Higher | Lower |

Looking to buy Carbon Steel Seamless Pipe & Tube?

Check price of BS 6323 Seamless Tubes, BS 3059 Seamless Tubes & St37 Seamless Tubes

ASTM A53 Seamless Manufacturing Process

ASTM A53 seamless pipes are produced by hot working solid steel billets through rotary piercing and elongation processes. The absence of a welded joint ensures consistent strength throughout the pipe body. Pipes may undergo heat treatment depending on size and application requirements to meet mechanical property standards.

ASTM A53 Seamless Grades

- Grade A Seamless – Moderate strength, structural and low-pressure use

- Grade B Seamless – Higher tensile strength, pressure and mechanical applications

ASTM A53 Grade B Seamless Pipe is the most popular grade that is supplied as it offers a trade off between strength, weldability and cost efficiency.

Contact us today for a quote on all your Carbon Steel Pipes & Tubes needs.

Table of Contents

- ASTM A53 Seamless Pipe Specifications

- ASTM A53 Pipes Chemical Composition

- Mechanical Properties of ASTM A53 Seamless Pipe

- ASTM A53 Steel Pipes Dimensions

- ASTM A53 Seamless Pipe Sizes

- ASTM A53 Pipe Wall Thickness

- ASTM A53 Grade B Pipe Pressure Rating

- Inspection & Testing for ASTM A53 Seamless Pipes

- Applications of ASME SA53 Seamless Pipe

- Why Buy ASTM A53 Seamless Pipe From USA Piping Solution?

- Related Products

- Frequently Asked Questions About for ASTM A53 Seamless Pipe

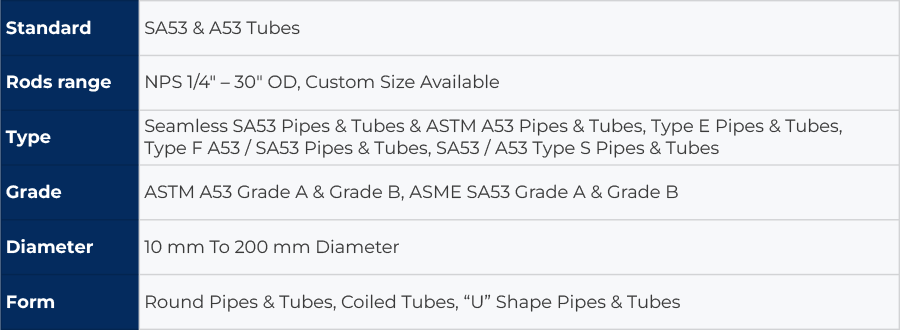

ASTM A53 Seamless Pipe Specifications

ASTM A53 Pipes Chemical Composition

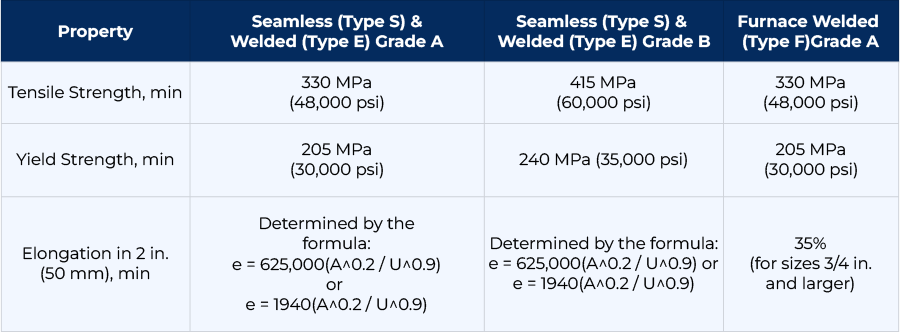

Mechanical Properties of ASTM A53 Seamless Pipe

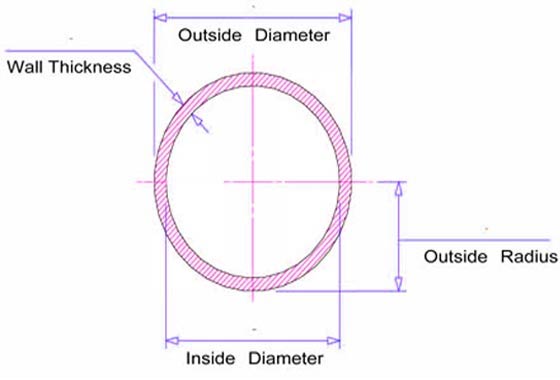

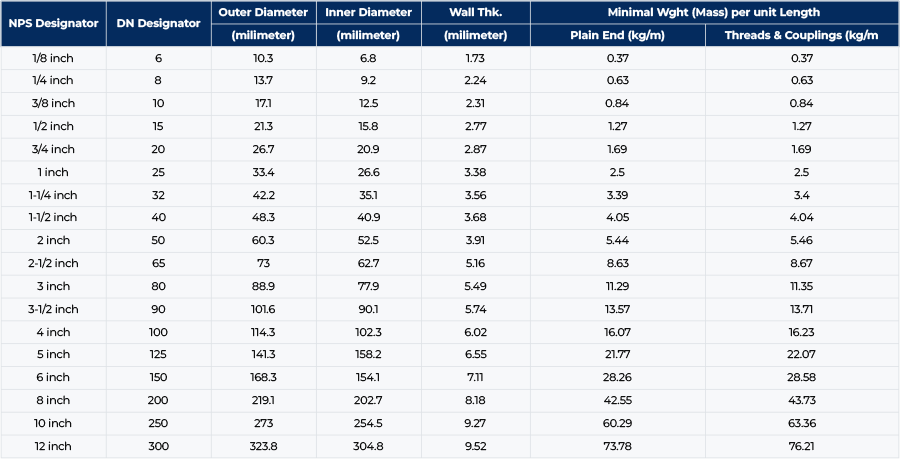

ASTM A53 Steel Pipes Dimensions

ASTM A53 Seamless Pipe Sizes

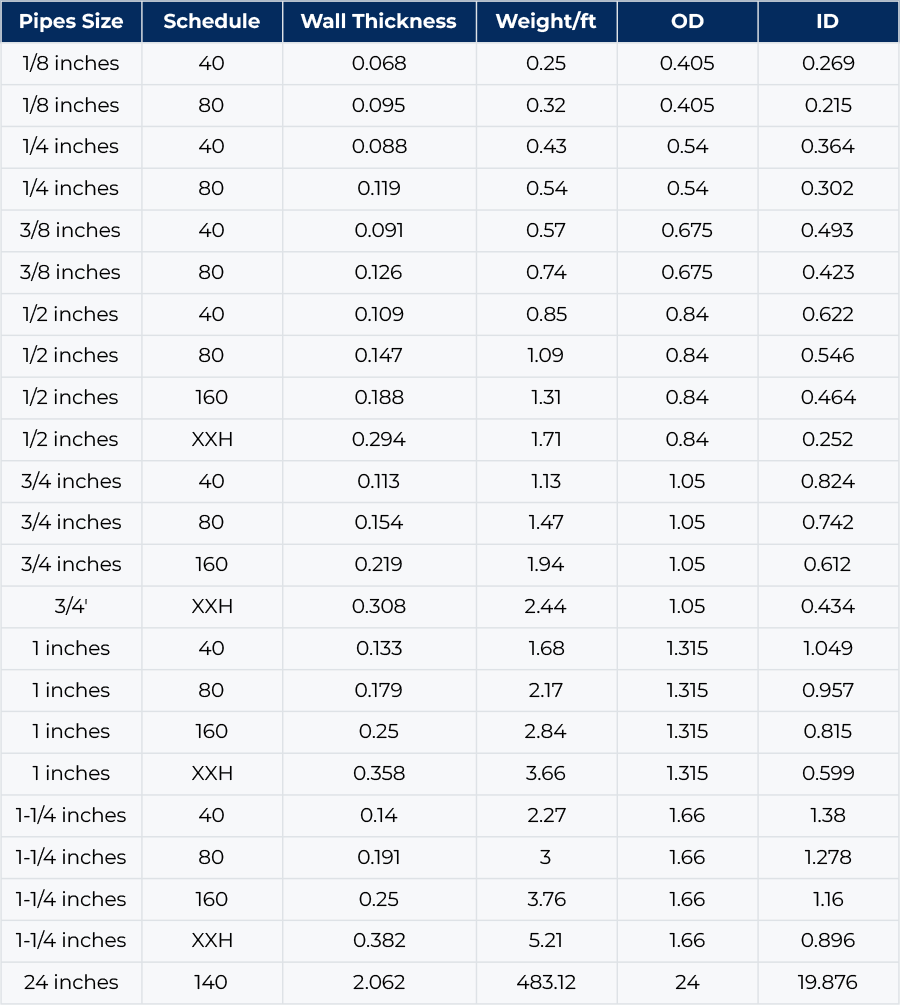

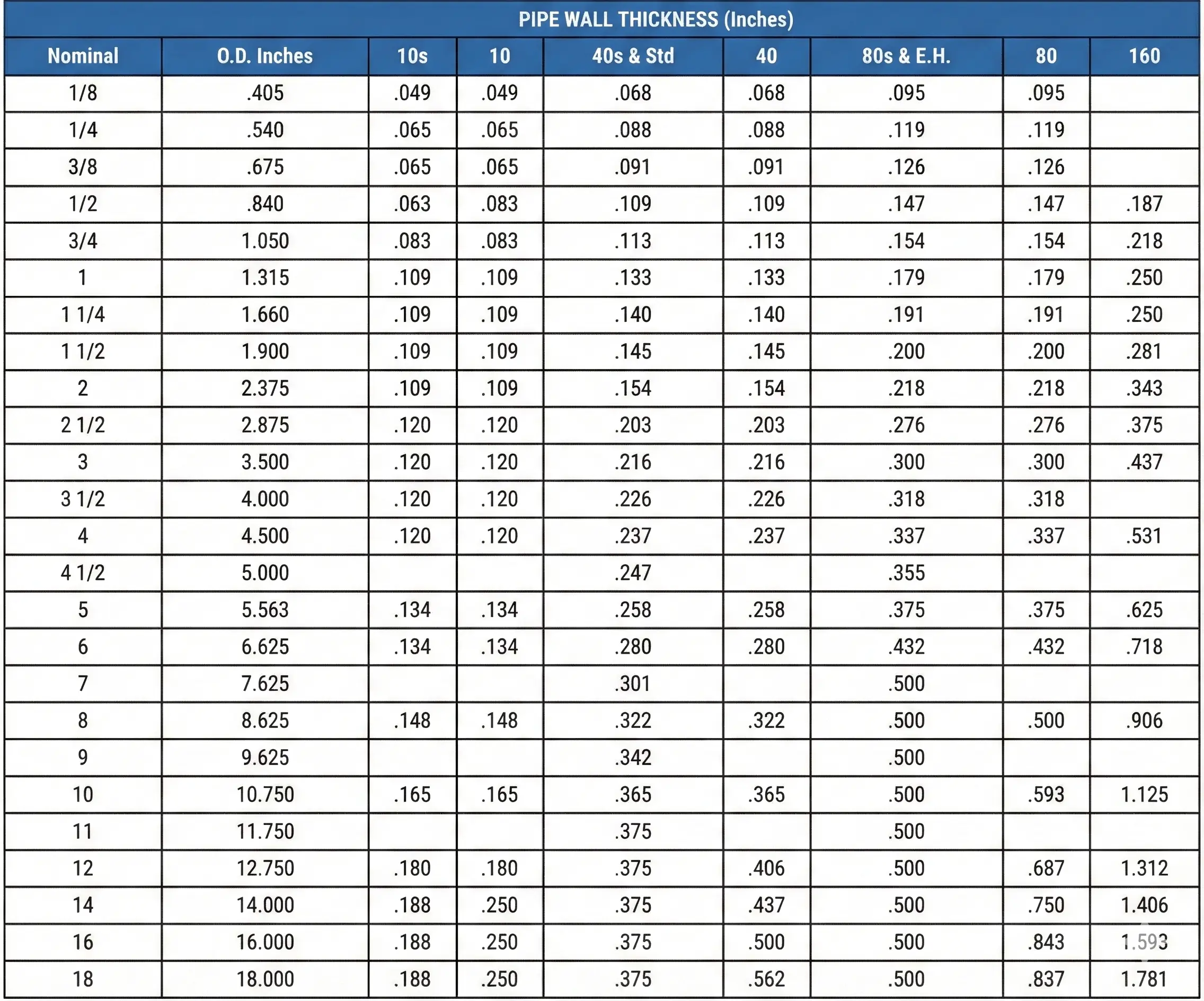

ASTM A53 Pipe Wall Thickness

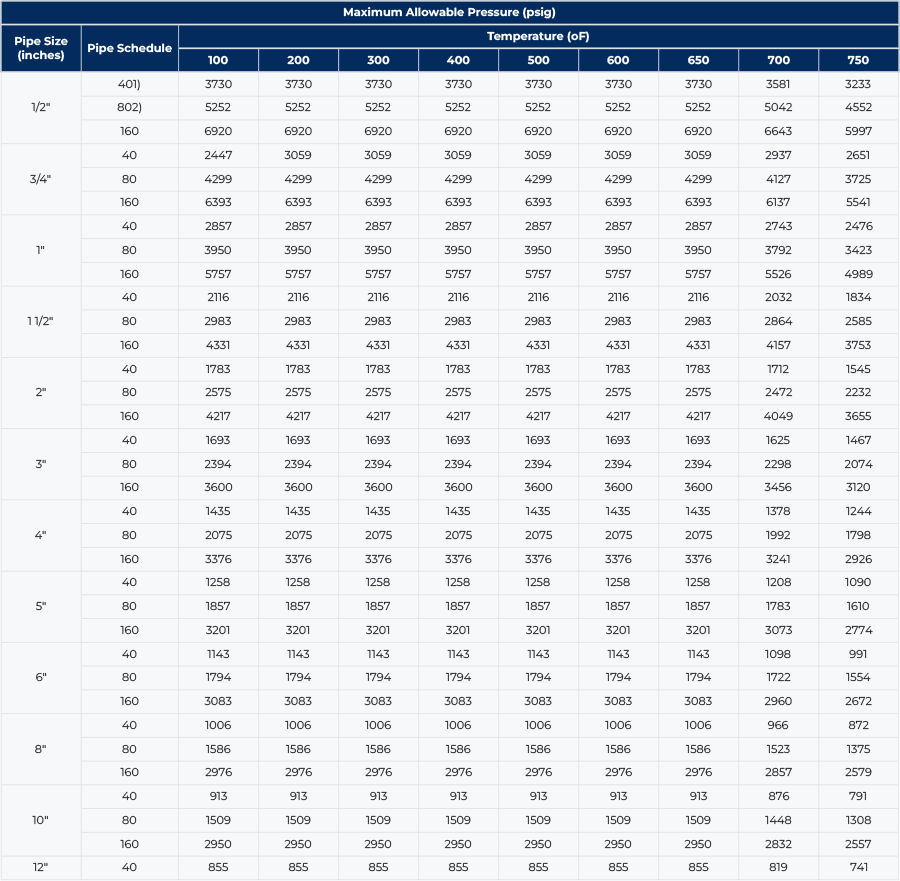

ASTM A53 Grade B Pipe Pressure Rating

Inspection & Testing for ASTM A53 Seamless Pipes

- Hydrostatic pressure testing

- Eddy current or ultrasonic testing (optional)

- Dimensional inspection

- Visual surface inspection

- Mill test certificate (EN 10204 3.1)

Applications of ASME SA53 Seamless Pipe

- Steam and pressure pipelines

- Oil & gas transmission systems

- Boiler and heat exchanger piping

- Structural and mechanical fabrication

- Power plants and refineries

.webp)

Why Buy ASTM A53 Seamless Pipe From USA Piping Solution?

- Stockist of ASTM A53 Grade B Seamless Pipes

- Ready inventory in standard & custom sizes

- PED / third-party inspection support

- Export packaging & global delivery

Related Products

API 5L Seamless Pipe

Built for oil and gas pipelines, with various grades for different pressures.

Request My A53 Pipe Quote Now!

Frequently Asked Questions About for ASTM A53 Seamless Pipe

What is ASTM A53 Gr B Pipe?

A53 Gr B is a type of carbon steel that has been developed to be used in low-pressure pipelines and structural steel. ASTM A53 Gr B Pipe is composed of an excellent chemical composition that comprises of carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum and powdered vanadium. This makes the A53 Gr B grade have better resistance to corrosive and oxidative media in stress-induced configurations. The A53 Pipe is versatile and could be produced with either smooth, welded or hot-dipped nominal grades that are able to be bent, flanked and undergo other special machining. The A53 Gr B Material portrays a high level of mechanical properties and also has a minimum yield strength of 240MPa and a minimum tensile strength of 415mpa. The maximum allowable wall thickness of the ASTM A53 Pipe in any location should not exceed beyond 12.5% of the indicated wall thickness.

What is ASTM A53 pipe used for?

ASTM A53 pipe has mostly been used in mechanical and pressure applications. Applications are in anti-static tubing in electric power stations, electrical supply of gas, and hydro electric power fluid pipeline. The pipes are also used in construction and are used in processing machinery.

Is A53 pipe galvanized?

A53 pipes are usually and readily hot-dipped galvanized. The galvanized coating, commonly referred to as a zinc coating, gives increased corrosion-resistant properties. This enables the A53 Grade B pipe to be confidentially employed in the challenging, stressful installations with great pressure and high temperature. (Note: The text originally has made an error and called a nickel coating; however, typical galvanizing is done with zinc.)

What is an ASTM A53 type F pipe?

ASTM A53 standard categorizes the pipe into three manufacturing types Type F (Furnace-Welded), Type E (Electric-Resistance-Welded) and Type S (Seamless), as well as two grades: A and B. The furnace weld or continuous welding (CW) process is used to make the A53 Type F Pipe. Notably, Type F piping is only offered in Grade A as opposed to Type E (ERW) and Type S (Seamless) which is offered in Grade A and Grade B.

Does A53 Grade B include seamless pipe?

Yes, A53 Grade B is used on seamless pipes of nominal sizes between 1/8 NPS and 26 NPS. This incredibly popular product can be either dual-certified to ASTM A106 Grade B (a high-temperature service specification, in particular). The seamless A53 pipes are made through either hot-rolled process or cold-drawn process. The hot-rolled process makes use of shaping hot steel billets whereas the cold-drawn process requires extra processes such as perforation, annealing and pickling to produce a better surface finish and finer dimensional controls.

.webp)