USA Piping Solution is a leading manufacturer, supplier and exporter of all types of Inconel 718 Flanges to clients in the global market. Our flanges provide great strength, long-term durability and performance in extreme conditions. The main characteristic of our Inconel 718 Slip On Flanges is their UNS N07718 material including the niobium element, which permits age-hardening. This allows for simple annealing and welding of Inconel 718 Flanges without the spontaneous hardening associated with the heating and cooling

ASTM B564 Inconel 718 Threaded Flanges, Inconel 718 Spacer, Inconel 718 Pipe Flanges, ANSI B16.5 Alloy 718 Blind Flanges, Inconel 718 Plate Flange, Inconel 718 Flanges Exporter, 718 Alloy Weld Neck Flange Supplier in USA

We have a wide range of flange options available, including Inconel 718 Threaded Flanges, Inconel 718 Weld Neck Flanges, Inconel 718 Socket Weld Flanges and Inconel 718 Blind Flanges. These components are suitable for aerospace, gas turbines, rocket motors, spacecraft, nuclear reactors and high-pressure pumps and turbo pump seals. The performance of the alloy is attributed to its use permanently above 600 Degree C (a refractory super-alloy) and niobium works with molybdenum to stiffen the matrix and maintain high strength for the alloy.

We have a selection of specialized flanges available in our inventory, including Inconel 718 Nippolet Flanges, ASTM B564 Alloy 718 Lap Joint Flanges, and Inconel 718 Blind Spectacle Flanges. As one of the premier dealers and exporters, we ensure that all products, including ANSI B16.5 Alloy 718 Blind Flanges, meet the highest standards. These high-integrity flanges are also widely used in jet engines, hot extrusion tooling, and nuclear fuel element spacers. We offer a range of different sizes and shapes to satisfy all customer specifications.

Request Quote !

Inconel 718 Pipe Flanges Specifications

To ensure optimal performance and compatibility in critical systems, our Inconel 718 Flanges are manufactured to the world's most rigorous material and dimensional standards.

| Specifications | ASTM B564 / ASME SB564 |

|---|---|

| Size | 1/2″ NB TO 60″ NB |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

Chemical Composition of Inconel Alloy 718 Pipe Flanges

The superior strength and corrosion resistance of Inconel 718 are derived from its precise chemical composition, specifically the addition of niobium.

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Mechanical Properties of Inconel 718 Flanges

These mechanical properties demonstrate the high strength, yield, and elongation capabilities of our Inconel 718 Plate Flanges in demanding high-temperature environments.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

Equivalent Grades for 718 Inconel Pipe Flanges

For projects requiring cross-referencing with international codes, here are the equivalent standards for our Inconel 718 Industrial Pipe Flanges.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

Types of Inconel 718 Flanges

We supply a complete range of flange types in Inconel 718, ensuring you have the correct fitting for every joint and pressure requirement.

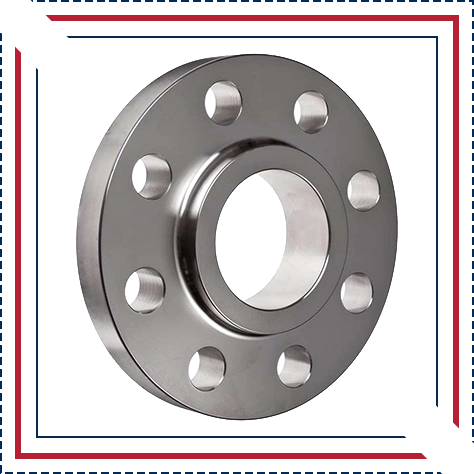

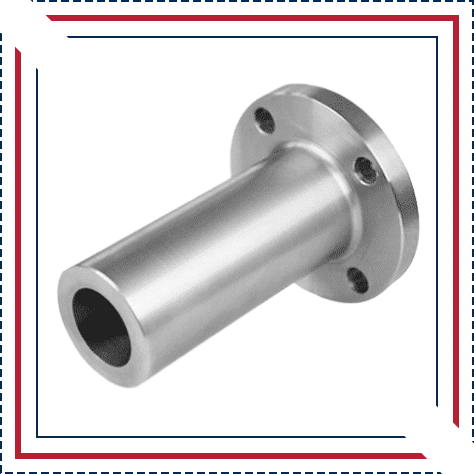

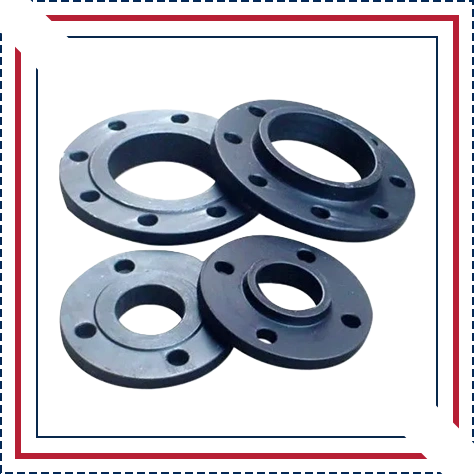

ASTM B564 UNS N07718 Slip On Flange

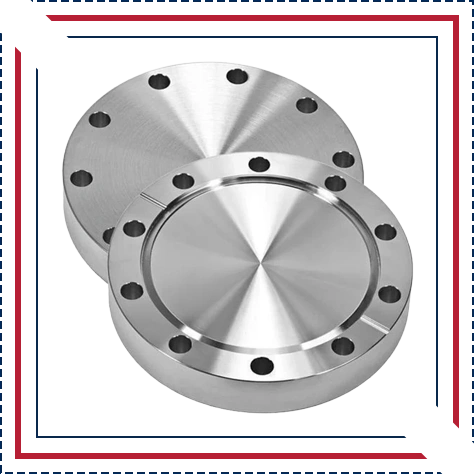

UNS 7718 Blind Flange

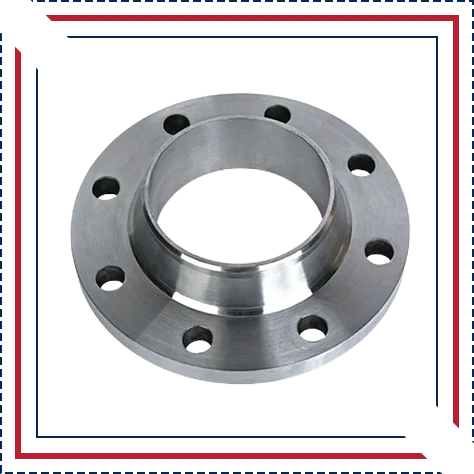

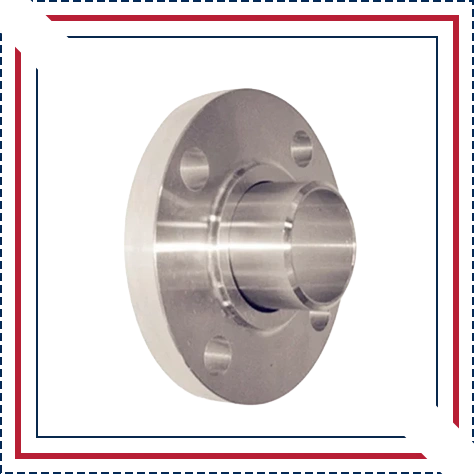

Inconel 718 Weld Neck Flange

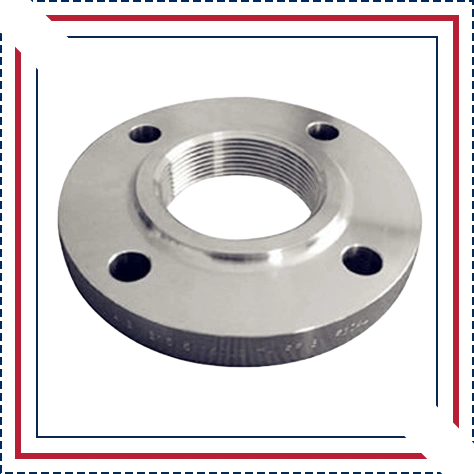

Inconel 2.4668 Threaded Flange

Inconel 718 Socket Weld Flange

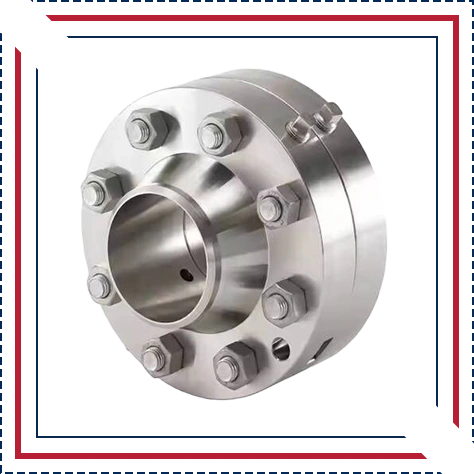

Alloy 718 Orifice Flanges

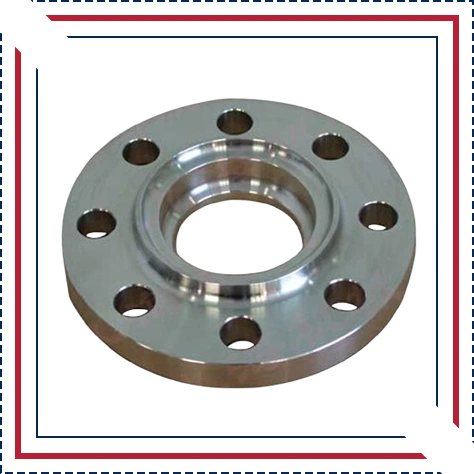

Nickel Alloy 718 Plate Flanges

718 Inconel Spectacle Blind Flange

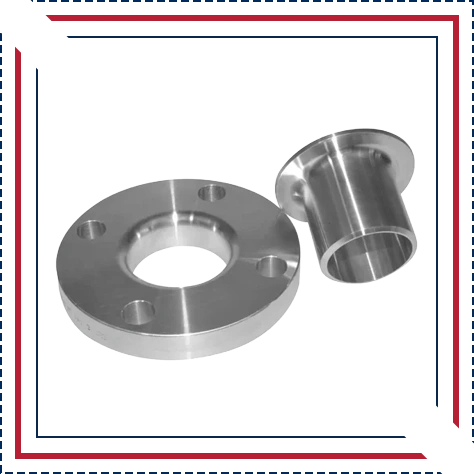

ASTM B564 UNS N07718 Lap Joint Flange

UNS N07718 Ring Type Joint Flange

Alloy Inconel 718 Expander Flange

DIN 2.4668 Swivel Flange

Pressure Rating Of Inconel 718 Pipe Flanges

The high-performance nature of Inconel 718 allows these flanges to handle extreme pressures; consult this chart for temperature-dependent rating details.

| Temp., °C | Working Pressures | ||||||

|---|---|---|---|---|---|---|---|

| 300 | 150 | 900 | 400 | 2500 | 1500 | 600 | |

| -29 ~ 38 | 51.7 | 20.0 | 155.1 | 68.9 | 430.9 | 258.6 | 103.4 |

| 100 | 51.5 | 17.7 | 154.6 | 68.7 | 429.4 | 257.6 | 103.0 |

| 200 | 48.6 | 13.8 | 145.8 | 64.8 | 405.4 | 243.4 | 97.2 |

| 250 | 46.30 | 12.1 | 139.0 | 61.7 | 386.2 | 231.8 | 92.7 |

| 325 | 41.4 | 9.3 | 124.0 | 55.0 | 344.3 | 206.6 | 82.6 |

| 350 | 40.3 | 8.4 | 120.7 | 53.6 | 335.3 | 201.1 | 80.4 |

| 400 | 36.5 | 6.5 | 109.8 | 48.9 | 304.9 | 183.1 | 73.3 |

| 425 | 35.2 | 5.5 | 105.1 | 46.5 | 291.6 | 175.1 | 70.0 |

| 475 | 31.7 | 3.7 | 95.1 | 42.3 | 263.9 | 158.2 | 63.4 |

| 500 | 28.2 | 2.8 | 84.7 | 37.6 | 235.0 | 140.9 | 56.5 |

| 550 | 13.9 | – | 41.8 | 18.6 | 116.2 | 69.7 | 27.9 |

| 600 | 6.6 | – | 19.9 | 8.9 | 55.3 | 33.2 | 13.3 |

| 650 | 4.7 | – | 14.2 | 6.3 | 39.4 | 23.6 | 9.5 |

Weight Chart of Nickel Alloy 718 Flanges

Use this chart to calculate the approximate weights for our standard Nickel Alloy 718 Flanges for planning and logistics purposes.

| NPS | Socket Weld | Threaded | Slip On | Lap Joint | Weld Neck | Blind |

|---|---|---|---|---|---|---|

| ½ | 2 | 2 | 2 | 2 | 3 | 2 |

| 1 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 |

| 1½ | 6.5 | 6.5 | 6.5 | 6.5 | 8 | 8 |

| 2 | 8 | 8 | 8 | 8 | 10 | 10 |

| 3 | 15 | 15 | 15 | 14 | 18 | 20 |

| 3½ | 21 | 21 | 21 | 20 | 26 | 29 |

| 5 | 31 | 31 | 31 | 29 | 43 | 44 |

| 6 | 44 | 44 | 44 | 42 | 57 | 61 |

| 10 | 91 | 91 | 91 | 110 | 125 | 155 |

| 12 | 130 | 130 | 130 | 152 | 175 | 226 |

| 16 | 253 | 253 | 253 | 280 | 295 | 398 |

| 18 | 310 | 310 | 310 | 345 | 360 | 502 |

| 22 | 405 | 405 | 405 | 455 | 505 | 720 |

Inconel Alloy 718 Plate Flange Schedule Chart

The following chart details the pipe wall thickness schedules compatible with our standard Inconel 718 Plate Flanges.

| Nom Pipe Size | OD | Sch 20 | Sch 60 | Sch 40 | Sch 120 | Sch 80 | XX Hvy | Sch 160 |

|---|---|---|---|---|---|---|---|---|

| ½ | 0.84 | …….. | …….. | 0.109 | …….. | 0.147 | 0.294 | 0.188 |

| 1 | 1.315 | …….. | …….. | 0.133 | …….. | 0.179 | 0.358 | 0.25 |

| 1 ½ | 1.9 | …….. | …….. | 0.145 | …….. | 0.2 | 0.4 | 0.281 |

| 2 | 2.375 | …….. | …….. | 0.154 | …….. | 0.218 | 0.436 | 0.344 |

| 3 | 3.5 | …….. | …….. | 0.216 | …….. | 0.3 | 0.6 | 0.438 |

| 4 | 4.5 | …….. | …….. | 0.237 | 0.438 | 0.337 | 0.674 | 0.531 |

| 6 | 6.625 | …….. | …….. | 0.28 | 0.562 | 0.432 | 0.864 | 0.719 |

| 8 | 8.625 | 0.25 | 0.406 | 0.322 | 0.719 | 0.5 | 0.875 | 0.906 |

| 12 | 12.75 | 0.25 | 0.562 | 0.406 | 1 | 0.688 | 1 | 1.312 |

| 16 | 16 | 0.312 | 0.656 | 0.5 | 1.219 | 0.844 | …….. | 1.594 |

| 18 | 18 | 0.312 | 0.75 | 0.562 | 1.375 | 0.938 | …….. | 1.781 |

| 22 | 22 | …….. | …….. | …….. | …….. | …….. | …….. | …….. |

| 24 | 24 | 0.375 | 0.969 | 0.688 | 1.812 | 1.219 | …….. | 2.344 |

| 30 | 30 | 0.5 | …….. | …….. | …….. | …….. | …….. | …….. |

| 36 | 36 | 0.5 | …….. | 0.75 | …….. | …….. | …….. | …….. |

| 42 | 42 | …….. | …….. | …….. | …….. | …….. | …….. | …….. |

ASTM B564 Inconel 718 Flange Dimension Chart

Refer to this chart for the critical dimensional data (OD, bolt circle, bore, etc.) of our standard UNS N07718 Flanges.

| Normal Sizes | Dimension | Class 300 | Class 600 | Class 400 | Class 1500 | Class 900 | Class 2500 | |

|---|---|---|---|---|---|---|---|---|

| inch. | inch. | inch. | inch. | inch. | inch | |||

| 1/2 | A | 3 3/4 | 3 3/4 | 3 3/4 | 4 3/4 | 4 3/4 | 5 1/4 | 133.4 |

| D2 | 1 3/8 | 1 3/8 | 1 3/8 | 1 3/8 | 1 3/8 | 1 3/8 | 34.9 | |

| D1 | 2 5/8 | 2 5/8 | 2 5/8 | 3 1/4 | 3 1/4 | 3 1/2 | 88.9 | |

| d | 5/8 | 5/8 | 5/8 | 7/8 | 7/8 | 7/8 | 22.2 | |

| 1 | A | 4 7/8 | 4 7/8 | 4 7/8 | 5 7/8 | 5 7/8 | 6 1/4 | 159 |

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| d | 3/4 | 3/4 | 3/4 | 1 | 1 | 1 | 25.4 | |

| 1 1/2 | A | 6 1/8 | 6 1/8 | 6 1/8 | 7 | 7 | 8 | 203 |

| D2 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 73 | |

| n | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| d | 7/8 | 7/8 | 7/8 | 1 1/8 | 1 1/8 | 1 1/4 | 31.8 | |

| 2 | A | 6 1/2 | 6 1/2 | 6 1/2 | 8 1/2 | 8 1/2 | 9 1/4 | 234.9 |

| D2 | 3 5/8 | 3 5/8 | 3 5/8 | 3 5/8 | 3 5/8 | 3 5/8 | 92.1 | |

Applications of Alloy 718 Flanges

Inconel 718 Flanges are important components for applications in challenging environments that require high strength, resistance to creep, and long-term stability at a high temperature.

- Off-Shore Oil Drilling Companies: Inconel 718 Flanges are widely used in offshore drilling and there are components used for wellhead equipment and downhole tools that require high strength and resistance to stress corrosion cracking.

- Power Generation: Inconel 718 Flanges are crucial to gas turbine components, heat exchangers, and steam generator components that require stability at high-temperatures.

- Petrochemicals & Gas Processing: Inconel 718 Flanges are very useful for high-pressure and high-temperature reactors, valves, and piping systems for chemical streams that are aggressive in nature.

- Specialty Chemicals: Common for chemical equipment where various corrosive media exist but must have structural integrity.

- Pharmaceuticals & Pharmaceutical Equipment: Inconel 718 Flanges are used for specialized processing equipment that must maintain material purity, resistance to cleaning agents, and functionality.

- Chemical Equipment: Used frequently in reactors and pressure vessels where superior mechanical properties and corrosion resistance are desirable.

- Sea Water Equipment & Condensers: Inconel 718 Flanges may be useful in limited scopes for marine applications requiring extreme strength, but copper-nickel is a common alternative solely for biofouling resistance.

- Heat Exchangers: Used in tube sheets and high-temperature locations requiring a high degree of thermal stability while also resistance to creep.

- Pulp and Paper Industry: Inconel 718 Flanges are generally used for specific locations of the plant (e.g., bleaching stage) requiring special characteristics.

Related Products

Inconel 718 Flanges Price List in USA

For the most competitive and current pricing on Inconel 718 Flanges in the USA, please contact our sales team directly. Quotes are determined by current market rates, specific size requirements, and order volume.

| Flange Type | USA Price (USD) |

|---|---|

| Alloy 718 Pipe Flanges | $80 – $200 per piece |

| 718 Inconel Flanges | $90 – $210 per piece |

| Inconel 718 Weld Neck Flanges | $100 – $220 per piece |

| ASTM B564 Inconel Alloy 718 Plate Flanges | $110 – $230 per piece |

Request a Quote!