Hot Finished Seamless Mechanical Tubing (HFS Tubing) is produced through hot working processes without cold drawing, resulting in tubing with relaxed residual stresses, improved concentricity, and stable dimensional performance. HFS mechanical tubing is commonly used for structural and mechanical applications where precision machining and uniform strength are required rather than pressure containment.

.png)

What Is Hot Finished Seamless Mechanical Tubing?

Hot Finished Seamless Mechanical Tubing (HFS) is a 1020/1026 carbon steel seamless mechanical tube that is manufactured by heating a solid bar of steel and turning it and piercing it to make a hollow tube. Since the tubing is not cold drawn but formed at high temperatures, residual stress levels are lower and stable mechanical properties are maintained, which allows the use of the tubing in heavy-wall applications and large-diameter tubing.

The HFS tubing is a cost-effective substitute of Cold Drawn Seamless (CDS) tubing that has a similar strength with a wider range of tolerance on outside diameter (OD) and inside diameter (ID). Hot finished seamless mechanical tubing is produced in OD and wall thickness dimensions, which easily make it suitable to be machined, bored, and fabricated.

.webp)

Benefits of Hot Finished Seamless (HFS) Tubing

- Cost-effective solution for heavy-wall tubing

- Easy machinability

- Excellent candidate for most processing techniques

- Wide range of sizes available

Looking to buy Corten Steel Pipes & Tubes?

Check price of ASTM A106 Grade B Seamless Pipe & ASTM A847 Tubes

Table of Contents

- Hot Finished Seamless Mechanical Tube Specifications

- ASTM A519 Hot Finished Seamless Tubing Chemical Composition

- Hot Finished Seamless Tubing Mechanical Properties

- Hot Finished Seamless Tubing Outside Diameter (OD) Tolerances

- Hot Finished Mechanical Tubing Wall Thickness Tolerances

- Hot Finished vs Cold Drawn Seamless Tubing

- Applications of Hot Finished Mechanical Tubing

- Inspection & Testing of HFS Tubing

- Related Products

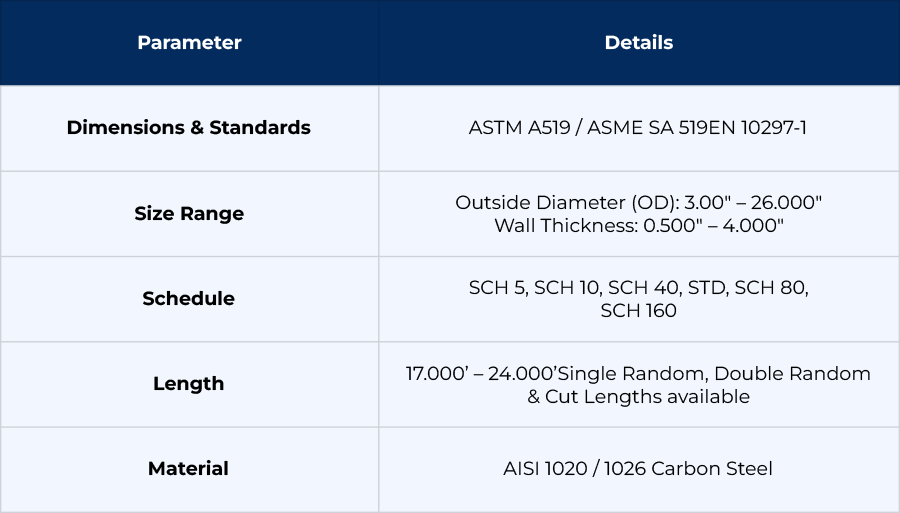

Hot Finished Seamless Mechanical Tube Specifications

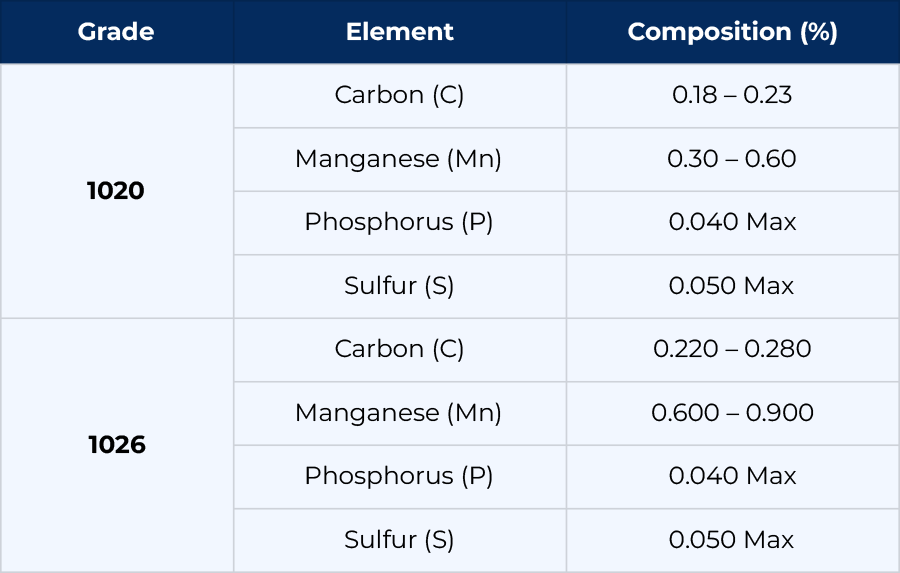

ASTM A519 Hot Finished Seamless Tubing Chemical Composition

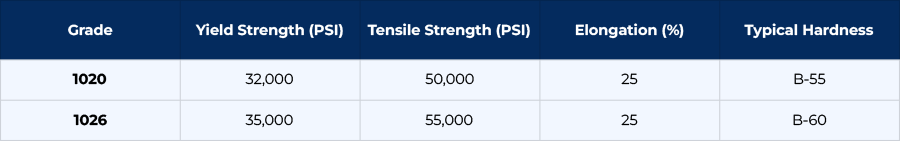

Hot Finished Seamless Tubing Mechanical Properties

Hot Finished Seamless Tubing Outside Diameter (OD) Tolerances

-Tolerances.png)

Hot Finished Mechanical Tubing Wall Thickness Tolerances

Request a Quote Now!

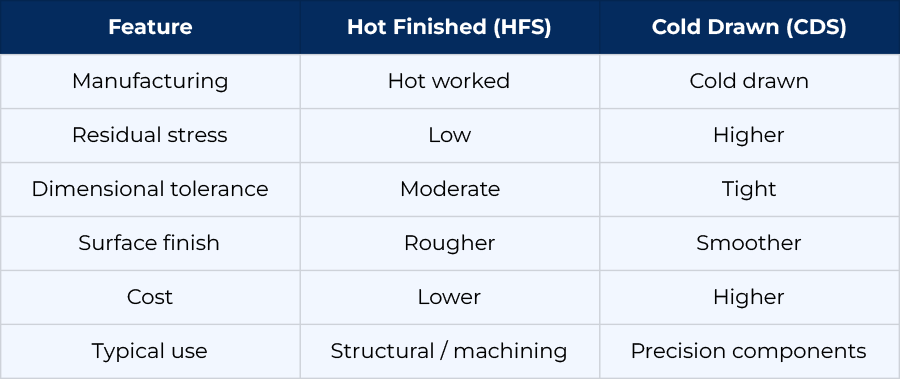

Hot Finished vs Cold Drawn Seamless Tubing

Manufacturing Process of HFS Mechanical Tubing

Hot finished seamless mechanical tubing is manufactured by heating steel billets and forming them into tubular shapes through rolling or extrusion. The tubing is allowed to cool naturally, resulting in stable mechanical properties and reduced internal stresses compared to cold worked tubing.

Grades Commonly Supplied in HFS Tubing

- ASTM A519 (1020, 1026)

- AISI 1020 / 1026

- EN & DIN mechanical steel grades (on request)

ASTM A519 Grade 1026 hot finished tubing is widely used for heavy-duty mechanical parts.

Applications of Hot Finished Mechanical Tubing

- Structural components and frames

- Hydraulic cylinder shells

- Machined parts and shafts

- Automotive and heavy equipment components

- General engineering fabrication

Inspection & Testing of HFS Tubing

- Dimensional tolerance verification

- Straightness and ovality checks

- Mechanical property testing

- Surface inspection

Why Choose USA Piping Solution for HFS Tubing?

- Stockist of hot finished seamless mechanical tubing

- Wide OD and wall thickness range

- Custom cut lengths available

- Export-ready packaging and documentation

Related Products

Request a Quote Now!

.webp)