Monel is an alloy of nickel and copper that has better performance regarding its corrosive resistance and high strength and toughness especially in unfavorable conditions, that is why Monel flanges are highly applied in critical systems in chemical, oil and gas, and marine sectors. The fact that Monel can survive, when exposed to seawater, brine as well as even hostile acids such as hydrofluoric acid, has made it applicable to numerous applications in the world that are extremely demanding.

Monel Flanges Manufacturer & Supplier in USA

USA Piping Solution is a reputable Manufacturer, Supplier, and Exporter of Monel Flanges. We adhere to delivering the highest quality products using technologically advanced equipment and high-quality materials. Our manufactured products meet national or international standards that exceed the overall performance and strength of our Monel Flanges in pipelines, valves, and essential components.

We provide an extensive selection of Monel flanges in Monel 400 and precipitation hardened Monel K500. We offer most standard assemblies in many standard sized ANSI/ASME flanges which include Weld Neck, Slip-on, Blind, Socket weld, lap joint, Screwed(threaded), and Reducing Flanges. We also provide custom flanges of several sizes, specifications and thicknesses beyond standard ANSI/ASME. All of the pipeline components can be made to order directly to your specifications for each project, number of parts, and applications that are critical to your needs. Whether your needs call for Monel flange options, or you want to learn more about the capabilities we have in forging and piping, call on USA Piping Solution for reliability and customer service.

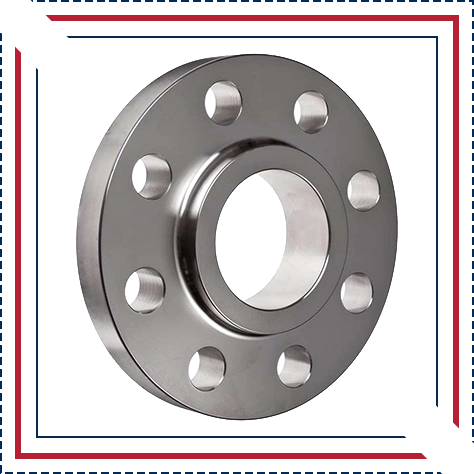

Monel 400 Flange

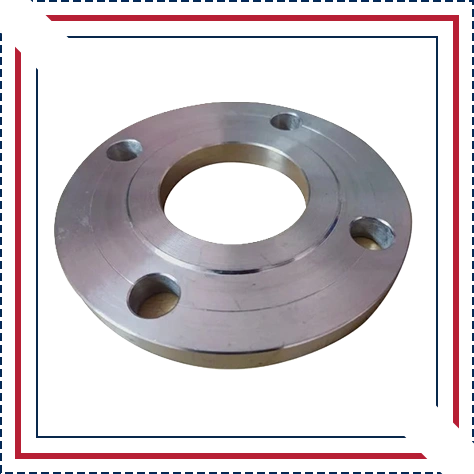

Monel K500 Flange

Request Quote !

Monel Flanges Specifications

To ensure global project compatibility, our Monel flanges meet the most demanding international material specifications and flange standards.

| Category | Specification Details |

|---|---|

| Material Spec | ASTM B564 / ASME SB564 |

| Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, JIS, UNI, GOST, AS2129, AWWA, NFE, SABS |

| Flange Standard (Detail) | ANSI B16.5, ANSI B16.47, MSS SP44, API 6A, AWWA C207, EN1092-1, JIS B2220, KS B1503, SABS1123, NFE29203, UNI2276, DIN (various) |

| Size Range | 1/2" (15 NB) to 48" (1200 NB) / DN10 to DN5000 |

| ANSI Pressure Class | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN/EN Pressure | PN6, PN10, PN16, PN25, PN40, PN64 |

| JIS Pressure | 5K, 10K, 16K, 20K, 30K, 40K, 63K |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, NACE MR0103, NACE MR0175 |

Monel Flanges Weight Chart

Refer to the table below for the estimated weight specifications of our standard Monel flanges, useful for logistics and engineering calculations

15mm (1/2") Monel Flanges Weight Chart

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 Flanges | PN14 Flanges | 95 | 67 | 4 | M12 | 14 |

| AS 2129 Flange | Table C Flanges | 95 | 67 | 4 | 13 | 14 |

| Table D Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table E Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table F Flanges | 95 | 67 | 4 | 13 | 14 | |

| Table H Flanges | 114 | 83 | 4 | 16 | 17 | |

| Table J Flanges | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 Flanges | ANSI 150 Flanges | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 Flanges | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 Flanges | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) Flange | PN6 Flanges | 80 | 55 | 4 | M10 | 11 |

| PN10 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN16 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN20 Flanges | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 Flanges | 95 | 65 | 4 | M12 | 14 | |

| PN40 Flanges | 95 | 65 | 4 | M12 | 14 |

Types of Monel Flanges

Monel flanges come in a variety of designs, each developed for their best possible performance in distinct piping designs and pressurized environments.

- Weld Neck Flanges: They feature a long tapered hub that effectively designs the stresses to the pipe connection since they are made for the more severe service conditions involving high pressures and temperatures.

- Slip-On Flanges:These flanges can be installed easily by sliding onto the pipe and then welding them in place, and are predominantly found in moderate to low pressure systems.

- Socket Weld Flanges:These flanges are designed for strength and they utilize a socket connection welded to the pipe. They are typically utilized for smaller bore sizes and higher pressure conditions.

- Blind Flanges: These flanges are used to close or terminate the end of a piping system, valve, or pressure vessel opening. Blind flanges are used primarily for pressure testing, and to ensure the integrity of the piping system while it is being maintained.

- Threaded flanges:These flanges are screwed onto a pipe without welding and are used in non-critical, low pressure applications and in an area where flammable or explosive conditions exist such as a welding application.

- Lap Joint Flanges: These flanges function with a "stub end" which would be welded to the pipe, and free to rotate the flange is very valuable in aligning bolts and provides versatility when using flange fittings.

Applications of Monel Flanges

Monel flanges are crucial components that are applicable in most of the industries that are demanding due to their special features of strength and resistance to corrosion.

- Chemical industry: Monel flanges are also normally utilized to bolster assembling pipelines and equipment in regions of extremely corrosive substances and mediums with the view of having a safe and durable system.

- Aerospace industry: Monel is being applied in engine and structures components where corrosion resistance and temperature are of concern; hence Monel would be a good candidate to be considered in safety and performance applications.

- Oil and gas industry: Monel flanges are widespread in the bolting of pipelines and valves in the oil and gas industry, particularly sour gas, and on the offshore platforms, where considerations of high strengths and corrosion resistance are a factor.

- Marine industry: Marine use of monel products is vital in seawater use, and brine use. Monel is very resistant to corrosion, pitting and crevice attack; hence Monel finds its application in the marine system and ship construction, and in the desalination system.

Related Products

Monel Flanges Price List in USA

| Flanges | Price |

|---|---|

| Monel Flanges | US $0.5-900 / Piece (FOB Price) |

| Monel Pipe Flanges | US $300-400 / Ton (FOB Price) |

| Monel 400 Forged Flanges | US $1-800 / Piece (FOB Price) |

| Monel Socket Weld Flanges | US $0.5-900 / Piece (FOB Price) |

| Monel Blind Flanges | US $1-200 / Piece (FOB Price) |

Request a Quote!