USA Piping Solution is a reputable manufacturer, supplier, and exporter of Super Duplex Steel UNS S32750 Pipes & Tubes, and we are supplying products that comply with the ASTM/ASME requirements at a very affordable price all over the globe. Super Duplex S32750 and Super Duplex S32760 are a couple of the most well-known super duplex stainless steel grades for high-demand applications. Super duplex alloys are known for their exceptional corrosion resistance and very high mechanical strength, and Super Duplex S32750 and Super Duplex S32760 are widely used in chemical processing (among other applications), oil & gas pipelines, and offshore & marine engineering systems.

Super duplex S32750 and S32760 belong to the same family of super duplex steel but also have differences in chemical compositions. For instance, Super Duplex S32750 has approximately 25% chromium, 7% nickel, and 3.7% molybdenum, and UNS S32760 has approximately 25.4% chromium, 5.6% nickel, and 3% molybdenum. UNS S32760 has a slightly higher nitrogen content and also has a higher yield strength, which improves its use in aggressive environments rich with chloride.

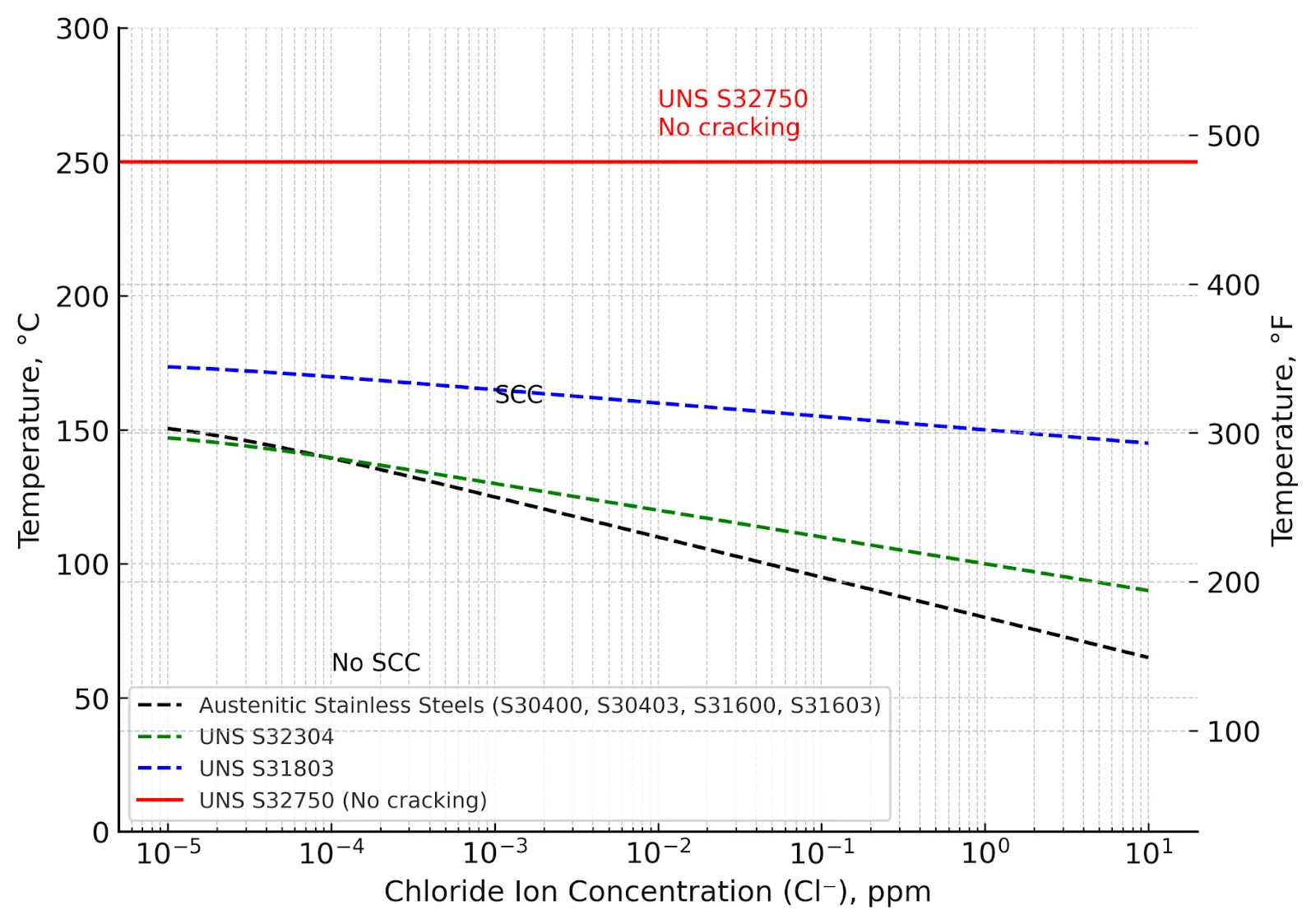

Super Duplex S32750, also referred to as Super Duplex Steel 2507, is an austenitic-ferritic type of Stainless Steel specifically engineered to provide excellent resistance to: pitting corrosion, crevice corrosion, and stress corrosion cracking in the presence of chlorides. Super Duplex Steel S32750 is alloyed with chromium, molybdenum, nickel and nitrogen, enabling superior corrosion resistance and enhanced mechanical properties.

With a tensile strength of ~800 MPa and outstanding resistance to fatigue, UNS S32750 is reliable for employment in offshore platforms, desalination plants and chemical processing facilities. The alloy also has a large yield strength, exceptionally durability and formability, which enables it to be ideal for use as Super Duplex Steel S32750 pipes & tubes in harsh conditions. The grade has a low thermal coefficient of expansion, and high thermal conductivity to ensure stability within dimensional tolerances through the heat-cool cycle, specifically to not deform from temperature variations and other environmental influences. Finally, its resistance to both organic acids and inorganic acids makes it an attractive design material for critical process industries.

Specifications of Super Duplex Steel S32750 Pipes & Tubes – UNS S32750 Material Properties

High-Performance Super Duplex Steel S32750 Pipes & Tubes (UNS S32750-WNR 1.4410) are high-performance alloys that are designed to provide strength, corrosion resistance and toughness. S32750 alloy material conforms to ASTM A790 / ASME SA790 and meets the mechanical and corrosion requirements for use in offshore, marine and chemical processing applications.

|

Specification |

Details |

|---|---|

|

Grade |

Super Duplex Steel UNS S32750 |

|

Size Range |

1/2" NB to 30" NB |

|

Standards |

ASTM A790 / ASME SA790, A815 |

|

Seamless Pipe/Tube Sizes |

1/2" NB – 10" NB |

|

Welded Pipe/Tube Sizes |

6" NB – 30" NB |

|

Available Forms |

Round, Square, Rectangular, Hydraulic |

|

Schedules |

SCH05, SCH10, SCH20, SCH30, SCH40, STD, SCH60, SCH80, XS, SCH120, SCH140, SCH160, XXS |

|

Lengths |

Single Random, Double Random, Cut Length |

|

Types |

Seamless, ERW, Welded, Fabricated, EFW |

|

End Finishes |

Plain End, Beveled End, Threaded |

|

Test Certificates |

MTC, IBR TC, Lab TC from Govt.-Approved Lab, Third-Party Inspection |

The requirements above also allow Super Duplex Steel UNS S32750 pipes and tubes to be furnished in exact sizes and shapes to meet exacting project requirements. Multiple schedule options offered by the specifications allow for selection depending on desired pressure handling requirements, while compliance with the ASTM and ASME requirements ensure the maximum quality, reliability, and safety. Variety of end finishes and certified testing also provides options for applications in critical industrial environments where performance and tolerances are not negotiable.

Dimensions of Super Duplex Stainless Steel 2507 / UNS S32750 Pipes & Tubes

It is a dimensional reference to properly size Super Duplex 2507 / UNS S32750 pipes and tubes in regard to Nominal Pipe Size (NPS), outside diameter, and nominal wall thickness for the various schedules. This dimensional reference is in compliance with super duplex S32750 mechanical properties and with ASTM standards. The information provided in this don't forget the importance to engineers, fabricators, and procurement will be selecting pipe dimensions appropriate for high pressure and corrosive service conditions.

|

NPS (mm) |

NPS (inch) |

OD (mm) |

Sch 5s |

Sch 10S |

Sch 20 |

Sch 30 |

Sch 40 |

STD |

Sch 80 |

XS |

Sch 160 |

XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

8 |

1/4 |

13.7 |

0.54 |

– |

1.65 |

– |

1.85 |

2.24 |

2.24 |

3.02 |

3.02 |

– |

|

10 |

3/8 |

17.1 |

0.675 |

– |

1.65 |

– |

1.85 |

2.31 |

2.31 |

3.20 |

3.20 |

– |

|

15 |

1/2 |

21.3 |

0.84 |

1.65 |

2.11 |

– |

2.41 |

2.77 |

2.77 |

3.73 |

3.73 |

4.78 |

|

20 |

3/4 |

26.7 |

1.05 |

1.65 |

2.11 |

– |

2.41 |

2.87 |

2.87 |

3.91 |

3.91 |

5.56 |

|

25 |

1 |

33.4 |

1.32 |

1.65 |

2.77 |

– |

2.90 |

3.38 |

3.38 |

4.55 |

4.55 |

6.35 |

|

32 |

1 1/4 |

42.2 |

1.66 |

1.65 |

2.77 |

– |

2.97 |

3.56 |

3.56 |

4.85 |

4.85 |

6.35 |

|

40 |

1 1/2 |

48.3 |

1.90 |

1.65 |

2.77 |

– |

3.18 |

3.68 |

3.68 |

5.08 |

5.08 |

7.14 |

|

50 |

2 |

60.3 |

2.38 |

1.65 |

2.77 |

– |

3.18 |

3.91 |

3.91 |

5.54 |

5.54 |

8.74 |

|

65 |

2 1/2 |

73.0 |

2.88 |

2.11 |

3.05 |

– |

4.78 |

5.16 |

5.16 |

7.01 |

7.01 |

9.53 |

|

80 |

3 |

88.9 |

3.50 |

2.11 |

3.05 |

– |

4.78 |

5.49 |

5.49 |

7.62 |

7.62 |

11.13 |

|

90 |

3 1/2 |

101.6 |

4.00 |

2.11 |

3.05 |

– |

4.78 |

5.74 |

5.74 |

8.08 |

8.08 |

– |

|

100 |

4 |

114.3 |

4.50 |

2.11 |

3.05 |

– |

4.78 |

6.02 |

6.02 |

8.56 |

8.56 |

13.49 |

|

125 |

5 |

141.3 |

5.56 |

2.77 |

3.40 |

– |

– |

6.55 |

6.55 |

9.53 |

9.53 |

15.88 |

|

150 |

6 |

168.3 |

6.62 |

2.77 |

3.40 |

– |

– |

7.11 |

7.11 |

10.97 |

10.97 |

18.26 |

|

200 |

8 |

219.1 |

8.62 |

2.77 |

3.76 |

6.35 |

7.04 |

8.18 |

8.18 |

12.70 |

12.70 |

23.01 |

|

250 |

10 |

273.0 |

10.75 |

3.40 |

4.19 |

6.35 |

7.80 |

9.27 |

9.27 |

15.09 |

12.70 |

28.58 |

|

300 |

12 |

323.8 |

12.75 |

3.96 |

4.57 |

6.35 |

8.38 |

10.13 |

9.53 |

17.48 |

12.70 |

33.32 |

|

350 |

14 |

355.6 |

14.00 |

3.96 |

4.78 |

7.92 |

9.53 |

11.13 |

9.53 |

19.05 |

12.70 |

35.71 |

|

400 |

16 |

406.4 |

16.00 |

4.19 |

4.78 |

7.92 |

9.53 |

12.70 |

9.53 |

21.44 |

12.70 |

40.49 |

|

450 |

18 |

457.0 |

18.00 |

4.19 |

4.78 |

7.92 |

11.13 |

14.27 |

9.53 |

23.83 |

12.70 |

45.24 |

|

500 |

20 |

508.0 |

20.00 |

4.78 |

5.54 |

9.53 |

12.70 |

15.09 |

9.53 |

26.19 |

12.70 |

50.01 |

|

550 |

22 |

559.0 |

22.00 |

4.78 |

5.54 |

9.53 |

12.70 |

– |

9.53 |

28.58 |

12.70 |

53.98 |

|

600 |

24 |

610.0 |

24.00 |

5.54 |

6.35 |

9.53 |

14.27 |

17.48 |

9.53 |

30.96 |

12.70 |

59.54 |

|

650 |

26* |

660.0 |

26.00 |

– |

– |

– |

– |

– |

9.53 |

– |

12.70 |

– |

|

700 |

28* |

711.0 |

28.00 |

– |

– |

– |

– |

– |

9.53 |

– |

12.70 |

– |

|

750 |

30* |

762.0 |

30.00 |

– |

– |

– |

– |

– |

9.53 |

– |

12.70 |

– |

|

800 |

32* |

813.0 |

32.00 |

– |

– |

– |

– |

– |

9.53 |

– |

– |

– |

- NPS: Nominal Pipe Size for quick reference

- OD: Outside diameter in millimeters

- Schedules: Wall thickness options to match required pressure ratings and mechanical strength

- “–” indicates that the dimension is not applicable or not standard for that size and schedule.

These measurements can be very useful when selecting appropriate pipe sizes for a number of applications including high-pressure pipelines, marine systems, chemical processing, and structural frameworks.

ASTM A790 Super Duplex S32750 Pipes & Tubes Size Range – UNS S32750 Material

Super Duplex Steel UNS S32750 seamless pipes are available in a wide range of diameters and wall thicknesses to fit a variety of industrial applications.

The following table provides exact measurements that include:

- Pipe size in inches

- Outside diameter (OD) in inches & millimeters

- Nominal wall thickness in inches & millimeters

- Cross-sectional area (external & internal) in square inches and mm²

- Length per surface area, volume per foot, and weight in lb/ft and kg/m

- Thread count for screw ends where applicable

These dimensions help engineers ensure accurate selection for pressure ratings, flow capacity, and mechanical requirements.

|

Pipe Size (in) |

Diameter (in) |

Diameter (mm) |

Nominal Thickness (in) |

Nominal Thickness (mm) |

External Area (in²) |

Internal Area (in²) |

External Area (mm²) |

Internal Area (mm²) |

Length per External Surface (ft) |

Length per Internal Surface (ft) |

Volume (ft³/ft) |

Weight (lb/ft) |

Weight (kg/m) |

Threads per inch |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1/8 |

0.405 |

10.29 |

0.07 |

1.78 |

0.13 |

0.06 |

9.43 |

14.20 |

0.0004 |

0.24 |

0.36 |

27 |

||

|

1/4 |

0.540 |

13.72 |

0.09 |

2.29 |

0.23 |

0.10 |

7.07 |

10.49 |

0.0007 |

0.42 |

0.63 |

18 |

||

|

3/8 |

0.675 |

17.15 |

0.09 |

2.29 |

0.36 |

0.19 |

5.66 |

7.75 |

0.0013 |

0.57 |

0.84 |

18 |

||

|

1/2 |

0.840 |

21.34 |

0.11 |

2.77 |

0.55 |

0.30 |

4.55 |

6.14 |

0.0021 |

0.85 |

1.26 |

14 |

||

|

3/4 |

1.050 |

26.67 |

0.11 |

2.77 |

0.87 |

0.53 |

3.64 |

4.64 |

0.0037 |

1.13 |

1.68 |

14 |

||

|

1 |

1.315 |

33.40 |

0.13 |

3.30 |

1.36 |

0.86 |

2.90 |

3.64 |

0.0060 |

1.68 |

2.50 |

11 ½ |

||

|

1 1/4 |

1.660 |

42.16 |

0.14 |

3.56 |

2.16 |

1.50 |

2.30 |

2.77 |

0.0104 |

2.27 |

3.38 |

11 ½ |

||

|

1 1/2 |

1.900 |

48.26 |

0.15 |

3.81 |

2.84 |

2.04 |

2.01 |

2.37 |

0.0141 |

2.72 |

4.04 |

11 ½ |

||

|

2 |

2.375 |

60.33 |

0.15 |

3.81 |

4.43 |

3.36 |

1.61 |

1.85 |

0.0233 |

3.65 |

5.43 |

11 ½ |

||

|

2 1/2 |

2.875 |

73.03 |

0.20 |

5.08 |

6.49 |

4.79 |

1.33 |

1.55 |

0.0333 |

5.79 |

8.62 |

8 |

||

|

3 |

3.500 |

88.90 |

0.22 |

5.59 |

9.62 |

7.39 |

1.09 |

1.25 |

0.0513 |

7.58 |

11.27 |

8 |

||

|

3 1/2 |

4.000 |

101.60 |

0.23 |

5.84 |

12.56 |

9.89 |

0.95 |

1.08 |

0.0687 |

9.11 |

13.56 |

8 |

||

|

4 |

4.500 |

114.30 |

0.24 |

6.10 |

15.90 |

12.73 |

0.85 |

0.95 |

0.0884 |

10.79 |

16.06 |

8 |

||

|

5 |

5.563 |

141.30 |

0.26 |

6.60 |

24.30 |

20.00 |

0.69 |

0.76 |

0.1389 |

14.61 |

21.74 |

8 |

||

|

6 |

6.625 |

168.28 |

0.28 |

7.11 |

34.47 |

28.89 |

0.58 |

0.63 |

0.2006 |

18.97 |

28.23 |

8 |

||

|

8 |

8.625 |

219.08 |

0.32 |

8.13 |

58.42 |

50.02 |

0.44 |

0.48 |

0.3552 |

28.55 |

42.49 |

8 |

||

|

10 |

10.750 |

273.05 |

0.37 |

9.40 |

90.76 |

78.85 |

0.36 |

0.38 |

0.5476 |

40.48 |

60.24 |

8 |

||

|

12 |

12.750 |

323.85 |

0.41 |

10.41 |

127.64 |

111.90 |

0.30 |

0.32 |

0.7763 |

53.60 |

79.77 |

8 |

||

|

14 |

14.000 |

355.60 |

0.44 |

11.18 |

153.94 |

135.30 |

0.27 |

0.28 |

0.9354 |

63.00 |

93.75 |

8 |

||

|

16 |

16.000 |

406.40 |

0.50 |

12.70 |

201.05 |

176.70 |

0.24 |

0.25 |

1.2230 |

78.00 |

116.08 |

8 |

||

|

18 |

18.000 |

457.20 |

0.56 |

14.22 |

254.85 |

224.00 |

0.21 |

0.23 |

1.5550 |

105.00 |

156.26 |

8 |

||

|

20 |

20.000 |

508.00 |

0.59 |

15.00 |

314.15 |

278.00 |

0.19 |

0.20 |

1.9260 |

123.00 |

183.05 |

8 |

||

|

24 |

24.000 |

609.60 |

0.69 |

17.53 |

452.40 |

402.10 |

0.16 |

0.17 |

2.7930 |

171.00 |

254.48 |

8 |

This dimension chart is useful for accurate material scheduling, and for selecting pipe sizes that meet flow rate, pressure-handling capacity, mechanical strength, and all align with ASTM A790 to provide you with compatibility in global engineering projects.

Equivalent Grades – Super Duplex Steel 2507 / UNS S32750 Pipes & Tubes

Super Duplex Steel 2507 / UNS S32750 is recognized across the world with various standards and material numbering systems.

The following table identifies its equivalents as per UNS (United Numbering System) and Werkstoffnummer (W.-Nr.) standards that provide compatibility across any number of international specifications.

|

Standard |

UNS |

Werkstoff Nr. |

|---|---|---|

|

Duplex 2507 |

S32750 |

1.4410 |

|

Duplex S32750 |

S32750 |

1.4410 |

Understanding equivalent grades permits engineers, suppliers and procurement teams to procure Super duplex steel S32750 materials, piping and tubes globally without misunderstanding over different terminology as it ensures compliance with standard and assists in matching mechanical, chemical and corrosion resistance features across regional specifications.

S32750 vs S32760 – Super Duplex Comparison

|

Property / Feature |

S32750 (Alloy 2507 / F53) |

S32760 (F55 / Zeron 100) |

|---|---|---|

|

Corrosion Resistance |

Excellent pitting and crevice corrosion resistance in chloride-rich environments |

Enhanced performance in acidic brines due to copper (Cu) and tungsten (W) additions; strong stress corrosion cracking resistance |

|

Composition Highlights |

~25% Chromium, 7% Nickel, 3–5% Molybdenum, 0.24–0.32% Nitrogen |

Similar base to S32750, plus Cu & W for specialized localized corrosion resistance |

|

Mechanical Strength |

Yield Strength ≥ 550 MPa, Tensile Strength ≥ 795 MPa |

Yield Strength ≥ 550 MPa, Tensile Strength ≈ 750–800 MPa; excellent impact properties |

|

Density |

7.8 g/cm³ |

7.8 g/cm³ |

|

PREN Value (Pitting Resistance Equivalent Number) |

> 40 |

> 40 |

|

Max Operating Temperature |

~250 °C |

~250 °C |

|

Applications |

Desalination plants, chemical processing, offshore oil & gas, marine systems, petrochemical plants |

Acid pickling plants, brine handling systems, sour gas environments, chemical tankers |

|

Notable Alloying Elements |

Higher molybdenum & nitrogen for enhanced corrosion resistance |

Copper & tungsten for improved localized corrosion resistance in aggressive solutions |

|

Typical Standards / Specifications |

ASTM A790 / ASME SA790, EN 10216-5 |

ASTM A790 / ASME SA790, NORSOK M-630 |

Super Duplex UNS S32750 Chemical Composition – 2507 / UNS S32750 Pipes & Tubes

The chemical composition of S32750 provide Super Duplex Steel UNS S32750 Pipes & Tubes with outstanding corrosion resistance and mechanical strength described as follows. The super duplex S32750 material contains chromium, nickel, molybdenum and nitrogen to provide outstanding pitting and crevice corrosion resistance.

|

Grade / UNS |

C (%) |

Cr (%) |

Ni (%) |

Mo (%) |

N (%) |

Mn (%) |

Cu (%) |

W (%) |

S (%) |

Si (%) |

|---|---|---|---|---|---|---|---|---|---|---|

|

S32750 |

≤ 0.03 |

24.0 – 26.0 |

6.0 – 8.0 |

3.0 – 5.0 |

0.24 – 0.32 |

≤ 1.20 |

≤ 0.50 |

– |

– |

– |

|

2507 |

≤ 0.03 |

24.0 – 26.0 |

6.0 – 8.0 |

3.0 – 5.0 |

0.24 – 0.32 |

≤ 1.20 |

≤ 0.50 |

– |

– |

– |

- High Chromium & Molybdenum: Provides superior pitting and crevice corrosion resistance

- Nitrogen Addition: Enhances mechanical strength and corrosion performance

- Low Carbon Content: Reduces the risk of intergranular corrosion during welding

- Balanced Alloying: Ensures excellent performance in aggressive chloride-containing environments

Super Duplex s32750 mechanical properties – 2507 / UNS S32750 Pipes & Tubes

The S32750 mechanical properties of Super Duplex Stainless Steel UNS S32750 Pipes & Tubes provide high yield strength, excellent tensile material and ductility performance. This suggests that super duplex stainless steel UNS S32750 would be perfect for offshore, desalination and chemical processing systems.

|

Grade |

Yield Strength (MPa) |

Ultimate Tensile Strength (MPa) |

% Elongation |

Hardness (BHN) |

|---|---|---|---|---|

|

UNS 2750 |

≥ 550 |

≥ 795 |

≥ 15 |

≤ 310 |

|

UNS S32750 |

≥ 550 |

≥ 795 |

≥ 15 |

≤ 310 |

- High Yield & Tensile Strength: Twice as strong as conventional austenitic stainless steels, allowing for thinner wall construction and reduced weight.

- Good Ductility: Minimum elongation of 15% ensures the material can handle forming, bending, and fabrication without cracking.

- Controlled Hardness: Maximum hardness of 310 BHN for optimal machinability and resistance to wear.

Material Properties – Super Duplex Steel UNS S32750

Super Duplex UNS S32750 (WNR 1.4410) is designed to have high mechanical strength, excellent corrosion resistance and high fatigue performance.

The table below shows the major physical and mechanical properties of the steel which will assist engineers and buyers in assessing if the steel would be suitable for particular applications.

|

Property |

Value / Description |

|---|---|

|

Density |

7.8 g/cm³ |

|

Melting Point |

~1350°C (2460°F) |

|

Yield Strength (0.2% proof) |

≥ 550 MPa |

|

Tensile Strength |

≥ 795 MPa |

|

Elongation |

≥ 15% |

|

Hardness (BHN) |

≤ 310 |

|

Modulus of Elasticity |

~200 GPa |

|

Impact Energy (Charpy V-Notch) |

High toughness at sub-zero temperatures |

|

Thermal Conductivity |

~14 W/m·K |

|

Coefficient of Thermal Expansion (20–100°C) |

~13.7 µm/m·°C |

|

PREN (Pitting Resistance Equivalent Number) |

> 40 |

|

Corrosion Resistance |

Excellent resistance to pitting, crevice corrosion, and chloride SCC |

Overall, these properties are the reason that UNS S32750 is often the material of choice for marine, offshore, petrochemical and high-pressure applications. It has a very high PREN value and strength, which are suitable for the longest service life in the harshest of environments in chloride-rich and aggressive conditions.

Super Duplex Steel S32750 Pipes & Tubes Price in USA – UNS S32750 Material

Super Duplex Steel 2507 / UNS S32750 pipes and tubes are high-quality materials, and price in the USA is dependent on various factors, including manufacturer, order quantity, surface finish, and overall demand for alloy steels at the time. The table below reflects an indicative price range per kilogram, and can help procurement teams budget going forward for future projects.

|

Country / Region |

Pipes Price (per kg) |

Tubes Price (per kg) |

|---|---|---|

|

India (₹) |

800 – 850 |

825 – 875 |

|

Malaysia (RM) |

43.44 – 46.16 |

44.80 – 47.52 |

|

Singapore (S$) |

12.97 – 13.78 |

13.38 – 14.19 |

|

UAE (Dirham) |

35.96 – 38.21 |

37.08 – 39.33 |

|

UK (£) |

7.76 – 8.25 |

8.00 – 8.49 |

|

Europe (€) |

8.88 – 9.43 |

9.16 – 9.71 |

|

USA ($) |

9.79 – 10.40 |

10.10 – 10.71 |

Bulk orders often qualify for preferential pricing, and rates can vary with surface finish, wall thickness, and specific testing requirements (e.g., PMI, hydro testing, third-party inspections). For the most accurate and competitive quote, request a formal quotation from certified Super Duplex 2507 suppliers in your region.

Note:Prices are indicative and may fluctuate based on global nickel costs, production expenses, and currency exchange rates.

Types and Variations of S32750 Pipes & Tubes

USA Piping Solution offers S32750 in forms suited to various needs:

- Seamless Pipes & Tubes: Uniform structure, ideal for high pressure/temperature and critical integrity needs.

- Welded Pipes & Tubes: Cost-effective option made via ERW or EFW methods, suitable for many applications. Post-weld treatments ensure optimal properties.

- Round, Square, Rectangular: Standard shapes for fluid transport and structural use.

- Hydraulic & Instrumentation: Small diameter, high precision tubes for control systems.

- U-Tubes: Custom bent for heat exchanger efficiency.

- Coiled Tubing: Long lengths for minimizing joints in chemical injection or control lines.

- Polished Finishes: Available for aesthetic, sanitary, or specific corrosion needs.

We supply the right configuration of Duplex Steel S32750 Tubes and pipes for your application.

Applications and Industries Served

S32750's properties make it indispensable in tough industries:

- Oil & Gas: Offshore platforms, subsea equipment, pipelines (resists chlorides, H₂S).

- Chemical Processing: Handling aggressive chemicals, acids, chloride streams in reactors, piping.

- Petrochemicals: High temperature/pressure, corrosive refining processes.

- Marine: Seawater cooling, ballast systems, desalination, structures.

- Desalination: High-pressure piping, pumps, heat exchangers handling brine.

- Pulp & Paper: Bleaching equipment, digesters resisting corrosive chemicals.

- Power Generation: FGD systems, geothermal/nuclear components, cooling systems.

- Mining: Handling abrasive and corrosive slurries.

- Structural: Bridges, coastal infrastructure requiring high strength and corrosion resistance.

- Pollution Control: Scrubbers, wastewater treatment handling aggressive effluents.

S32750 offers long-term cost-effectiveness through enhanced service life and reliability.

Certifications and Compliance Standards

Quality assurance is key. All our S32750 Pipes & Tubes come with full documentation:

- Mill Test Certificates (MTC): Per EN 10204 3.1 standard, detailing chemistry, mechanical properties, heat treatment, NDE results, and traceability. EN 10204 3.2 (third-party witnessed) available on request.

- NACE MR0175 / ISO 15156: Certification for sour service suitability available.

- PED Compliance: Materials can be certified for European Pressure Equipment Directive requirements.

- Third-Party Inspection (TPI): We welcome client-appointed agencies (Lloyd's, DNV, BV, etc.).

- Additional Testing: Can be arranged (specific corrosion tests, impact tests, advanced NDE, PMI).

Our system ensures materials are fully compliant and documented.

FAQs for the Product

Related Products

We also supply related piping materials:

Super Duplex S32760 Pipes & Tubes

Duplex S31803 / S32205 Pipes & Tubes

S32750 Fittings (Buttweld, Forged)

S32750 Flanges

S32750 Bars, Plates, Sheets

Austenitic Stainless & Nickel Alloy Products