USA Piping Solution is a distributor and supplier of corten steel products, also referred to as weathering steel. Corten Steel is special in the sense that it is created to withstand rust, when uncoated it develops a layer called patina on its surface. This patina is successful in stopping the further corrosion of the steel below.

We have a vast product line, which comprises corten steel seamless pipes & tubes, Corten steel Welded Pipes, and grades with specifications as ASTM A423 A Gr.1 tubes and ASTM A847 Hss Welded Square Pipe. We are stocked with different grades such as CORTEN A, CORTEN B, ASTM A423 GRADE 1, ASTM A847 tubes, ASTM A588 to mention but a few that are at competitive prices.Our Corten Steel Pipes and Tubes are produced in line with the national and international quality requirements. Our inventory of standard sizes, materials and types of pipes is diverse, thus we are able to deliver instantly to the world at affordable prices.

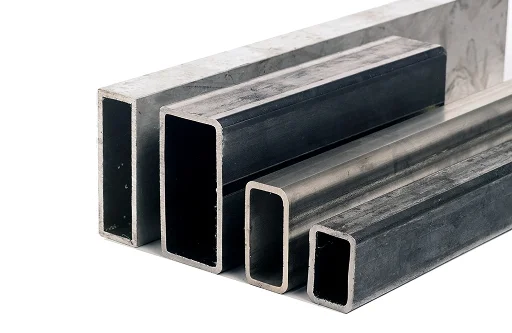

We manufacture high-quality Square Corten Steel Pipes, Hollow Corten Steel Pipes, Rectangular Corten Steel Pipes, and Round Corten Steel Pipes with various wall thicknesses with the sole purpose of having a strong pipeline use.

What are Corten Steel pipes and tubes?

Corten Steel pipes and tubes are produced out of various grades of weathering steels, which are named so due to their quality of weathering, and their ability to form the distinctive layer of oxide, or patina, on the surface. It is the distinctive identifier of this material; as it is exposed to the atmosphere, it will create a protective layer of the material that is thin and serves as a kind of coating against further oxidation.

These types of steel are used in other specialized uses like in Exhaust Pipe systems. An example of this is the ASTM A847 specification that identifies high-strength low alloys that can be welded and bolstered and used in the areas that demand high corrosion resistance and structural integrity. Our pipes and tubes are of high quality and have a nominal diameter of 1 inch to 6 inches and a wall thickness of 0.133 inches to 0.280 inches. The price list and specifications of our Grade 1 Corten Steel Pipe, Seamless Pipe and A847 Welded Pipe are available on request.

Table of Contents

Specifications of Corten Steel Pipes and Tubes

Our Corten Steel Pipes and Tubes are produced and supplied under a large number of international and structural project standards to assure compliance with the requirements of different international and structural projects. The size ranges, grades and dimensional standards that we abide by are detailed below.

| Size Range | ½ OD to 16 OD |

|---|---|

| Standards | ASTM A 423 GR. 1,ASME SA 423, ASTM A 847, ASTM 588, ASTM 606 |

| Grade | ASTM A 423 GR.1 , asme SA A423 , astm a 847, astm 606 |

| Shape | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| Length | Single Random, Double Random & Cut Length |

| End | Plain End, Beveled End |

| Type | Weathering steel / corten steel |

Chemical Composition of Corten Steel Pipes and Tubes

Corten Steel has unique weathering and corrosion-resistant characteristics which are made through its accurate chemical composition. Balanced incorporation of alloying elements forms the special protective patina layer which is described by the following formula as presented in the table below.

| COMPOSITION | Grade 1 | Grade 2 |

|---|---|---|

| Carbon, max | 0.15 | 0.15 |

| Manganese, max | 0.55 | 0.50–1.00 |

| Phosphorus | 0.06–0.16 | 0.04 max |

| Sulfur, max | 0.060 | 0.05 |

| Silicon, min | 0.10 | … |

| Copper | 0.20–0.60 | 0.30–1.00 |

| Chromium | 0.24–1.31 | … |

| Nickel | 0.20–0.70 | 0.40–1.10 |

| Molybdenum, min | … | 0.10 |

Mechanical Properties of Corten Steel Pipes & Tubes

Corten Steel is highly valued because of its high structural strength and durability and hence it is used in load bearing and demanding applications. The following table provided details of the important mechanical properties, such as tensile strength, yield strength and elongation of our different Corten steel grades.

| Grade | Yield Strength Min PSI | Tensile Strength Min PSI | Elongation % (min) |

|---|---|---|---|

| ASTM A847 | 50,000 | 70,000 | 19 |

Corten Steel Tubes Sizes In Inch

Our Corten Steel Tubes are available in a wide size when it comes to the requirements of the project. The table below lists the nominal sizes that are standardized in inches and availability of the same.

Availability

ASTM A847 – Square Tubing

| Normal Wall Thickness | 11ga. | 3/16 | 1/4 | 3/8 | 1/2 |

|---|---|---|---|---|---|

| 1 x 1 | ✓ | ||||

| 1-1/4 x 1-1/4 | ✓ | ||||

| 1-1/2 x 1-1/2 | ✓ | ✓ | ✓ | ||

| 2 x 2 | ✓ | ✓ | ✓ | ||

| 2-1/2 x 2-1/2 | ✓ | ✓ | |||

| 3 x 3 | ✓ | ✓ | ✓ | ||

| 3-1/2 x 3-1/2 | ✓ | ||||

| 4 x 4 | ✓ | ✓ | ✓ | ||

| 5 x 5 | ✓ | ✓ | ✓ | ||

| 6 x 6 | ✓ | ✓ | ✓ | ✓ | |

| 8 x 8 | ✓ | ✓ | ✓ | ||

| 10 x 10 | ✓ | ✓ | ✓ | ||

| 12 x 12 | ✓ |

**Inquire about sizes not listed

Corten Steel Tubing Pressure Rating

Understanding the performance capability of our tubing is crucial for engineering safety. This table provides the calculated pressure ratings for Corten Steel tubing across different wall thicknesses and nominal sizes, helping you determine suitability for your application.

| Pipe O.D. (in.) | Wall Thickness of Pipe/Tube (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Types of Corten Steel Pipes & Tubes

Our inventory features a comprehensive range of Corten Steel pipes and tubes categorized by manufacturing process, shape, and specialized application, including seamless, welded, square, and rectangular forms.

- Astm A847 Corten Steel Pipes

- Astm A606 Corten Steel Plates

- ASTM A242 Type 1 plate & Sheet

- Corten Steel ASTM A588 GR.A Plates

- ASME SA423 GR 1 Corten Steel Tube

- Corten Steel Astm A423 Gr1 Pipes & Tube

- Corten Steel IRSM 41-97 Steel Plate

- Corten Steel IRSM 41-97 Steel Plate / Sheet / Coil

- ASME SA588 GR B Plate

- Corten Steel ASME SA588 GR B Plate

- ASTM A847 Corten Steel Tube

Applications of Corten Steel Pipes & Tubes

Corten steel is also referred to as weathering steel, it is mostly applied in the areas where its distinctive corrosion resistance and rustic character can be exploited. It is best suited to difficult outdoor and industrial conditions because of its capability to develop a protective patina.

Marine industries: Corten steel pipes and tubes find a great demand in the marine industry because they have very good weather resistance. It is used in the construction of ships and marine containers as well as offshore structures whose components are in constant contact with saltwater, humidity, and corrosion in the atmosphere. The rust coating (patina) that develops on the surface of the steel guarantees the structural integrity of the material over an extended time and in very harsh environments (coastal and open-sea).

Petrochemical and Oil & Gas Industries: Corten steel is used in the Petrochemical and the Oil & Gas Industries in case of pipelines and structural elements that are prone to the effects of the corrosive fumes and chemicals as well as the elements of nature. Although it is not the best choice when it comes to transporting highly corrosive liquids such as stainless steel, its strength and resistance to overall degradation in the atmosphere makes it ideal in:

- External Piping and Ducting: This is applicable in the open sections of refineries and processing plants.

- Structural Supports: Frames and support structures of storage tanks and platform where high strength and low maintenance are needed.

- Exhaust Systems: Corten steel can withstand high temperature and corrosion hence is an excellent choice in exhaust systems in the industry.

Food Processing Industries: Corten steel is not normally applied to food or beverage direct contact in the Food Processing Industries. The reason is that its typical patina is a loose layer of oxide that may fall off and pollute products. Rather, this industry is very strict with materials that are highly sanitary and which are non-reactive such as Stainless Steel (particularly, grade 304 and 316) so as to maintain cleanliness and avert product contamination.

Related Products