Stainless Steel 304L Seamless Pipes and Tubes are produced using low-carbon austenitic stainless steel and it is designed with the aim of providing superior corrosion resistance, high weldability and structural stability. The minimal carbon content affirms the limited carbon precipitation, and so, stable performance is guaranteed even following a prolonged welding activity.

ASTM A312 TP304L seamless pipes are manufactured according to compliance, giving them uniform metallurgy, increased resistance against intergranular corrosion, and reliable pressure-handling, making them suited to the aggressive and welding-intensive industrial applications.

What Is Stainless Steel 304L Seamless Pipe?

Stainless Steel 304L seamless pipe is made by either hot extrusion or cold drawing using a weld free process resulting in a continuous homogeneous structure of the pipe. The L grade indicates low carbon, and this avoids corrosion and sensitization of the joint made.

SS 304L seamless tubing is highly favored in systems that are either exposed to corrosive media, subject to frequent welding or operating at higher temperatures, where long-term integrity and safety are paramount.

Looking to buy Stainless Steel Seamless Pipes and Tubes?

Check price of Stainless Steel 304 Seamless & Stainless Steel 316 Seamless Pipe

Table of Contents

- Difference Between SS 304 & SS 304L Seamless Pipes

- Why SS 304L Is Preferred for Seamless Pipe Applications

- ASTM Standards for 304L Stainless Steel Seamless Tubes

- Chemical Composition of SS 304L Seamless Pipes

- Grades & Forms of Stainless Steel 304L Seamless Tubes

- Size Range of SS 304L Seamless Pipes

- Applications of 304L Stainless Steel Seamless Pipes & Tubes

- Why Choose USA Piping Solution for SS 304L Seamless Pipes?

- Related Stainless Steel Products

Difference Between Stainless Steel 304 & 304L Seamless Pipes

The basic distinction between the Stainless Steel 304 and 304L seamless pipes is in the amount of carbon. The carbon content in SS 304L is less and this strongly minimises the chances of intergranular corrosion that follow welding.

In general pressure, SS 304 seamless pipes are used but in welding intensive fabrication, corrosive service environments and long term industrial exposure where post-weld heat treatment is not an option, SS 304L seamless pipes are used.

Why SS 304L Is Preferred for Seamless Pipe Applications

SS 304L seamless pipes are selected for critical piping systems where weld integrity, corrosion resistance, and extended service life are primary requirements.

- Low carbon stainless steel minimizes carbide precipitation

- Enhanced resistance to intergranular corrosion

- Excellent performance after welding without post-weld heat treatment

- Suitable for high-pressure and elevated temperature service

Longer service life in chemical, marine, and industrial environments

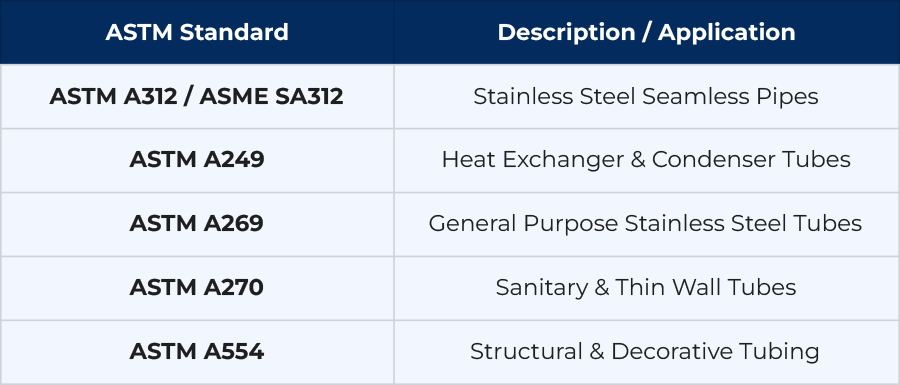

ASTM Standards for SS 304L Seamless Tubes

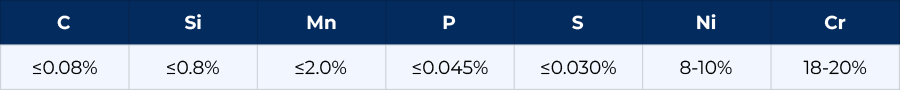

Chemical Composition of Stainless Steel 304L Seamless Pipes & Tubes

Low carbon content in SS 304L prevents intergranular corrosion after welding, making it ideal for seamless pipe applications.

Grades & Forms of 304L Stainless Steel Seamless Pipes & Tubes

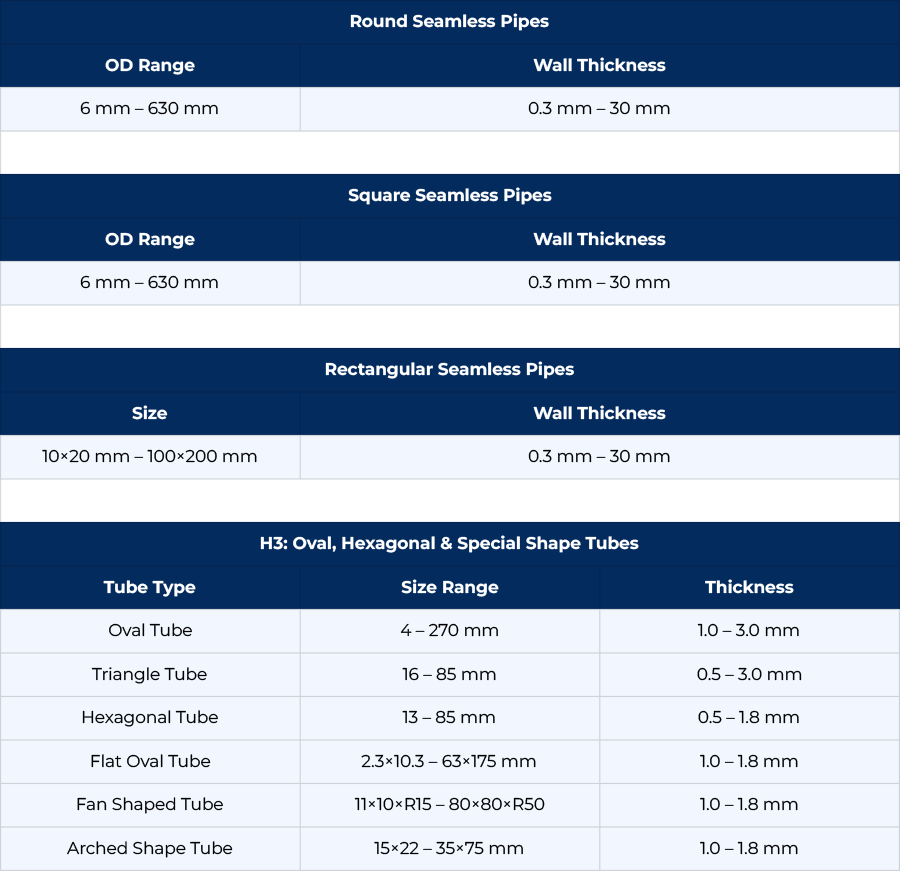

- Round Seamless Pipes

- Square Stainless Steel Tubes

- Rectangular Seamless Tubing

- Oval & Flat Oval Tubes

- Hexagonal & Triangle Tubes

- Fan Shaped & Arched Tubes

- Handrail Tubes

- Capillary & Inner Polished Tubes

Size Range of Stainless Steel 304L Seamless Pipes & Tubes

Applications of 304L Stainless Steel Seamless Pipes & Tubes

- Chemical & petrochemical processing pipelines

- Food & beverage processing equipment

- Pharmaceutical manufacturing systems

- Heat exchangers and condensers

- Oil & gas transportation lines

- Power generation and boiler systems

Why Choose USA Piping Solution for SS 304L Seamless Pipes?

- ASTM & ASME certified stainless steel materials

- ISO-certified manufacturing and quality control

- Third-party inspection (TPI, SGS, BV) available

- Custom sizes, schedules & cut lengths

- Fast delivery across the USA

- Proven export expertise across industries

Related Products