Stainless Steel 304L Welded Pipes & Tubes is made of a low-carbon austenitic stainless steel, which provides reliable tensile and yield strengths, as well as, excellent weld integrity. The regulated amount of carbon greatly increases the weldability and the stainless steel 304L pipes are ideal to use in fabricating projects where the activity involves high levels of welding. These welded pipes are manufactured under ASTM A312 TP304L ERW requirements and offer the same handling of pressure and a more cost-effective alternative to seamless tubing.

The welded pipes SS 304L are particularly used in case the post-weld corrosion resistance is required. The low carbon content prevents the formation of carbide in the welding process, which guarantees better resistance to the intergranular corrosion and stable operation in the environment of severe and high temperature conditions.

Stainless Steel 304L Welded Pipes and Tubes are available in a wide variety of sizes, wall-thicknesses and surface-finishes, and are used in corrosive and demanding environments. They are also a good fit in food processing equipment, chemical processing plants, pharmaceutical systems, and other high-stress industrial systems due to their capacity to endure high temperatures and high mechanical loads. The standard 304L stainless steel pipes are usually found in the 12-inch size to half an inch.

Looking to buy Stainless Steel Seamless Pipes and Tubes?

Check price of Stainless Steel 304 Seamless & Stainless Steel 304L Seamless

Table of Contents

- What’s the Difference between Stainless Steel 304 & 304L Welded Pipes & Tubes?

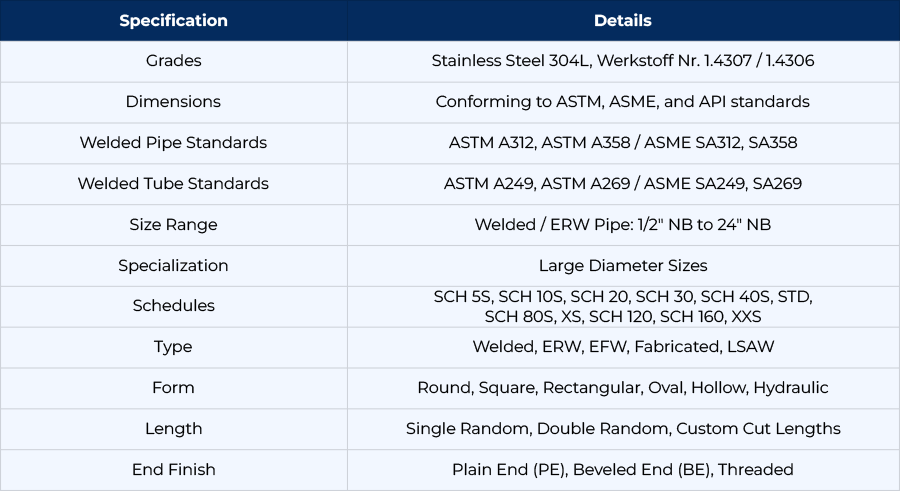

- Stainless Steel 304L Pipe & Tube Specifications

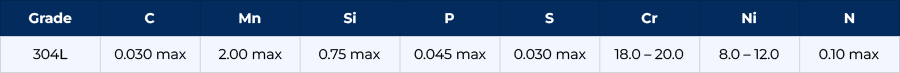

- Chemical Composition of Stainless Steel 304L Pipes

- Mechanical Properties of Stainless Steel 304L Pipes and Tubes

- Physical Properties of Stainless Steel 304L Pipes and Tubes

- Equivalent Grades for Stainless Steel 304L Pipes and Tubes

- Types of Stainless Steel 304L Pipes

- ASTM A312 TP304L ERW Pipe Schedule

- Applications of 304L Welded Pipes & Tubes

- Related Products

What’s the Difference between Stainless Steel 304 & 304L Welded Pipes & Tubes?

The similarity that exists between Stainless Steel 304 and Stainless Steel 304L Welded Pipes and Tubes is that, they belong to the austenitic structure with corrosion resistance, but the main difference between these two is the amount of carbon content and their performance during welding and high-temperature service. These variations enable each grade to be applicable to certain industrial requirements.

The stainless steel 304 Welded Pipes have a greater amount of carbon that offers a little higher tensile strength. Nonetheless, at the time of welding, this added carbon can cause carbide to form at the grain boundaries and this can lessen the corrosion resistance at the heat-affected areas unless heat treatment is provided immediately after welding. Consequently, general fabrication, structural and other areas where welding is not intensive are prevalent in SS 304 welded pipes.

Stainless Steel 304L Welded Pipes on the other hand are produced using a low-carbon composition that gives the material high resistance against intergranular corrosion following the welding process. This removes the use of post weld heat treatment in majority of the applications. Because of this merit, SS 304L welded pipes and tubes are very popular in any industries involving chemical processing, pharmaceuticals, food processing, and piping systems where frequent welding and exposure to corrosive media are encountered.

Performance wise, the two grades have high levels of durability, formability and oxidation resistance. The SS 304L welded pipes are however preferable in welded assemblies that require either a corrosive or high-temperature environment whereas the SS 304 welded pipes are a cheaper alternative to the general industrial use.

Stainless Steel 304L Welded Pipes are used in corrosive atmospheres with the aim of welded piping systems because it has low-carbon chemistry, thus it is the material to use in welded piping systems, though Stainless Steel 304 welded pipes is usually used in structural and general construction.

Stainless Steel 304L Pipe & Tube Specifications

Chemical Composition of Stainless Steel 304L Pipes

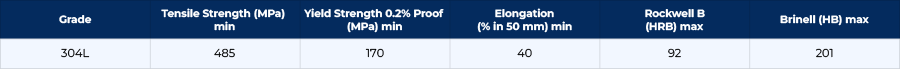

Mechanical Properties of Stainless Steel 304L Pipes and Tubes

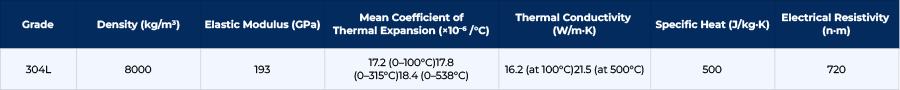

Physical Properties of Stainless Steel 304L Pipes and Tubes

Equivalent Grades for Stainless Steel 304L Pipes and Tubes

Types of Stainless Steel 304L Pipes

DIN 1.4307 Hollow Pipe

AISI 304L Seamless Pipe

SUS 304L Round Pipe

INOX 304L Exhaust Pipe

Stainless 304L Oval Pipe

304L SS Square Pipe

SS 304L Hexagonal Pipe

UNS S30403 Rectangular Pipe

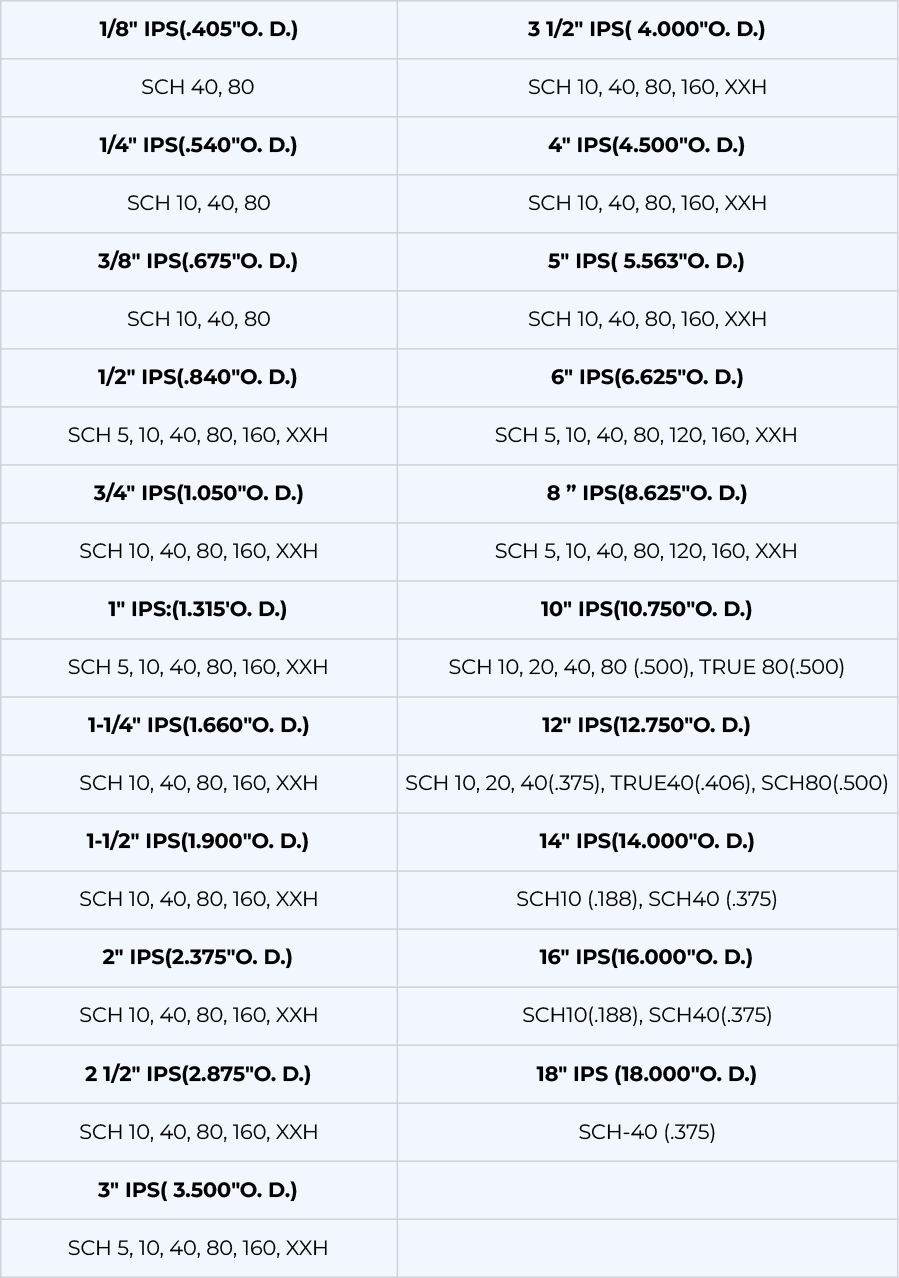

ASTM A312 TP304L ERW Pipe Schedule

Applications of 304L Welded Pipes & Tubes

- Chemical & Pharmaceutical Industry

- Food & Beverage Industry

- Architecture & Construction

- Water Treatment & Plumbing Systems

- Oil & Gas Industry

- Power Generation Plants

- Marine & Coastal Applications

- Automotive & Engineering Applications

Related Products