ASTM A249 TP304 Pipes, Stainless Steel 304 Welded Pipe, SS 304 Welded Pipe & Tube, Stainless Steel 304 ERW Pipe, Stainless Steel 304 Welded Tube, ASTM A312 SS 304 Stainless Steel Welded Pipes & Tubes Manufacturer & Supplier in USA

Stainless Steel 304 Welded Pipes and Tubes are an important part and parcel of industrial infrastructure designed to handle the pressure and temperatures of up to 870 C. They are normally produced according to the ASTM A249 TP304 standards and comprise a strong austenitic alloy of chromium, nickel, carbon and nitrogen, thus making them exceptionally ductile, tough and easy to weld via the traditional fusion methods. Having a tensile strength of around 621 Mpa (90 Ksi), SS 304 welded pipes provide an excellent resistance to oxidation and corrosion due to its composition that incorporated at least 18 percent chromium and 8 percent nickel compositions.

The versatility of Stainless Steel 304 Welded Pipe & Tube makes it the preferred choice for diverse sectors, including marine operations, chemical processing, food and beverage manufacturing, power industry and breweries. Having the density of 8 g/cm 3, these pipes are stable at high temperatures and have better creep resistance. Their combination of high formability, durability and strength make them fit the hard usage of petrochemical plants, pharmaceutical plants and other high pressure systems.

USA Piping Solutions specializes in SS 304 Welded Pipes and Tubes of all types, round, square and rectangular in shapes to match the exact specifications of projects, tolerances and any custom sizes. The SS 304 welded pipes contain greater amounts of carbon which increases tensile strength and rigidity and thus can be used in structural fabrication, industrial piping and pressure vessels where large post-weld corrosion resistance is not of high importance. ASTM A249 TP304 pipes are typically applied in heat exchangers and condensers whereas ASTM A312 TP304 pipes are applicable in general industrial applications. Stainless Steel 304 welded pipes are also ideal structural support, pressure-containing structures, and welded assembly without sensitization treatment because they are more rigid and stronger than low-carbon types.

Looking to buy Stainless Steel Seamless Pipes and Tubes?

Check price of Stainless Steel 304 Seamless & Stainless Steel 304L Seamless

Table of Contents

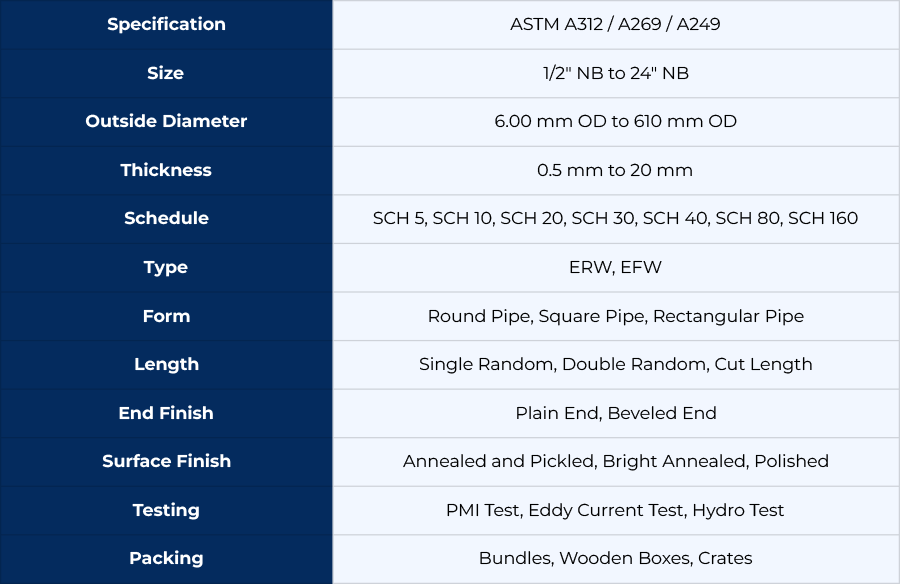

- Stainless Steel 304 Welded Pipe & Tube Specifications

- SS 304 Welded Pipe Equivalent Grades

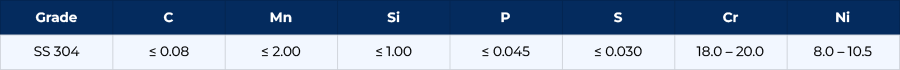

- A249 TP304 Welded Pipe & Tube Chemical Composition

- Stainless Steel 304 Welded Pipe Mechanical Properties

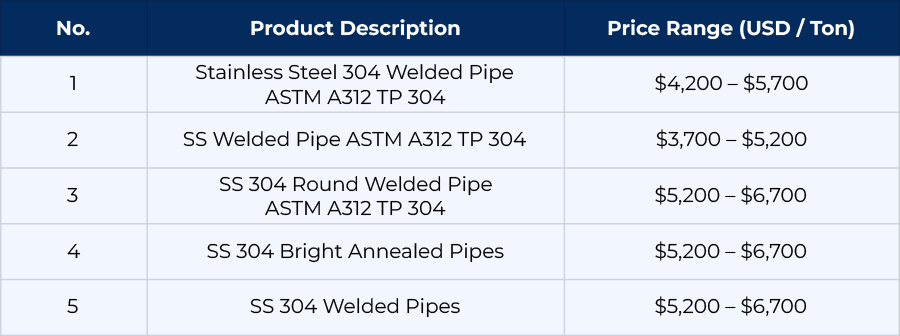

- Stainless Steel 304 Welded Pipes Prices

- Stainless Steel 304 Welded Pipe & Tube Applications

- Why Choose USA Piping Solution for SS 304 Welded Pipes?

- Related Products

Stainless Steel 304 Welded Pipe & Tube Specifications

SS 304 Welded Pipe Equivalent Grades

A249 TP304 Welded Pipe & Tube Chemical Composition

Mechanical & Physical Properties of Stainless Steel 304 Welded Pipe

<

<Stainless Steel 304 Welded Pipes Prices

Prices are indicative and may vary based on size, schedule, finish, and market conditions.

Request Your Quote Today!Stainless Steel 304 Welded Pipe & Tube Applications

- Chemical Industries

- Petrochemical Industries

- Oil & Gas Industry

- Food Processing Industry

- Power Plants

- Water Treatment Plants

- Pharmaceuticals

Why Choose USA Piping Solution for SS 304 Welded Pipes?

- ASTM & ASME Certified Materials

- Third-Party Inspection Availability

- Custom Sizes & Fast USA Delivery

- Extensive Export & Industry Experience

- ISO Certified Quality Management

Related Products